The Art and Science of Making Tempered Glass

Tempered glass, known for its strength and safety features, is a crucial material in modern architecture and everyday products

. The process of making tempered glass involves several intricate steps that enhance its durability, making it an essential choice for various applications, from building facades to smartphone screens.

The journey of tempered glass begins with the selection of high-quality raw materials, typically silica sand, soda ash, and limestone. These ingredients are meticulously mixed and melted in a furnace at temperatures exceeding 1,700 degrees Fahrenheit (about 927 degrees Celsius). This high-temperature environment ensures that the raw materials become a uniform molten glass, free from any impurities.

Once the glass reaches the desired consistency, it is carefully formed into sheets or shapes. This can be achieved through various methods such as blowing, pressing, or molding. The formed glass is then allowed to cool slowly in a controlled environment, transitioning to a state called annealed glass. While annealed glass is relatively strong, it does not have the same level of durability as tempered glass.

The heating process is followed by the crucial tempering phase. This involves reheating the glass sheets to around 1,200 degrees Fahrenheit (approximately 649 degrees Celsius). After achieving this high temperature, the glass is rapidly cooled through a process known as “quenching,” where high-pressure air is blown onto the surface. This rapid cooling creates a significant difference in temperature between the outer surface and the inner core of the glass.

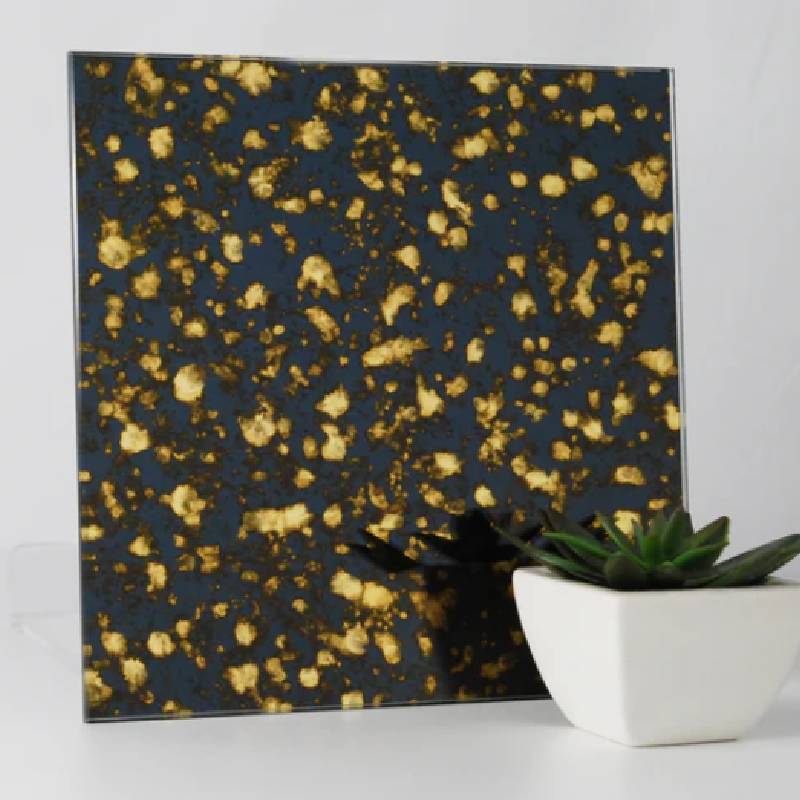

making tempered glass

The result of this thermal shock is a compressed outer layer that significantly increases the glass's strength. Tempered glass can withstand impacts and thermal stress far better than standard glass. This characteristic makes it a preferred choice in various demanding environments, including shower doors, glass doors and tables, and car windows.

An essential benefit of tempered glass is its safety feature when broken, it shatters into small, blunt pieces rather than sharp shards, reducing the risk of injury. This property is particularly important in public spaces and residential areas where safety is a paramount concern.

Moreover, the manufacturing process of tempered glass is not only efficient but also environmentally friendly. Many manufacturers utilize recycled glass in their production, thus contributing to a sustainable cycle. As building codes evolve and safety standards become stricter, the demand for tempered glass continues to rise.

In conclusion, the art and science behind making tempered glass exemplify the perfect blend of innovative engineering and craftsmanship. By transforming raw materials through heat and cooling processes, we produce a material that not only meets but exceeds the demands of modern applications, enhancing both safety and aesthetic appeal in our everyday lives.

Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu