The manufacturing of tempered glass is a process that combines art and science to produce one of the most robust safety materials used in various industries today. With over two decades of experience in the glass manufacturing field, I've observed the evolution of tempered glass production and its rising importance in sectors ranging from automotive to architecture.

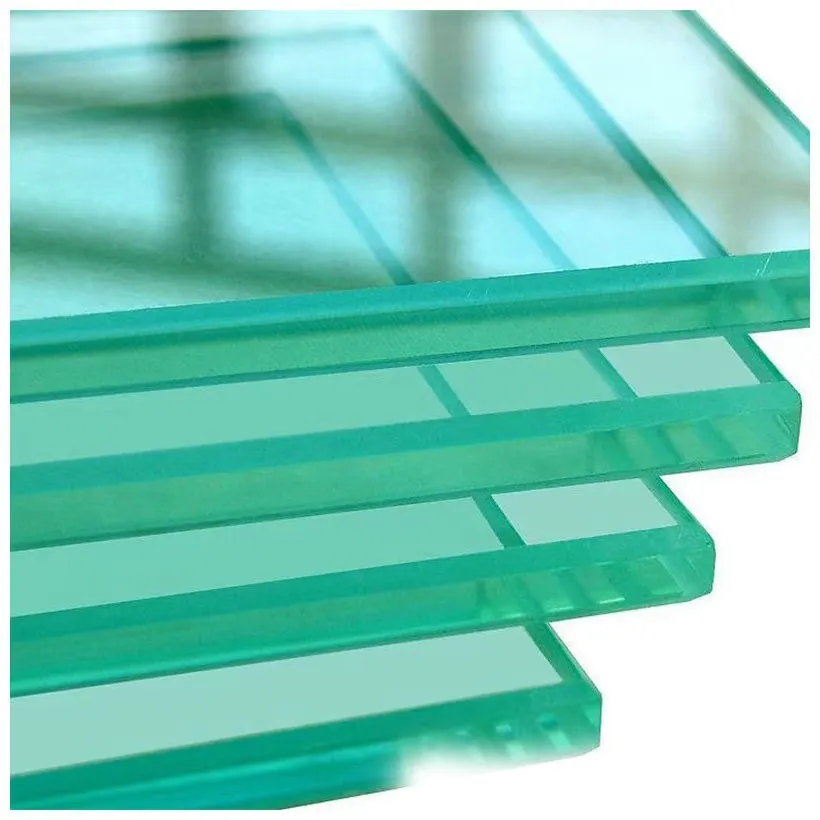

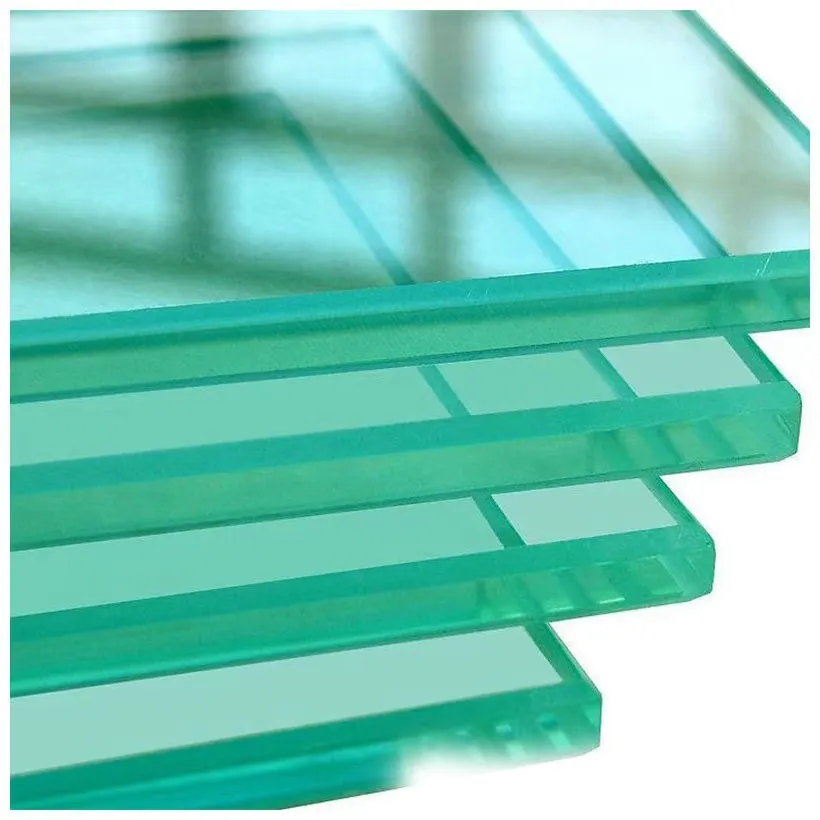

Tempered glass, renowned for its strength and durability, is created through a meticulous process that starts with heating the glass to over 600 degrees Celsius. This is followed by a rapid cooling phase known as quenching. The heating causes the surface to compress, while the interior remains in tension, giving tempered glass its remarkable strength, which is up to five times that of regular annealed glass.

From a professional standpoint, understanding the technical intricacies involved in creating tempered glass is crucial for manufacturers aiming to produce high-quality products. Expertise in areas such as glass chemistry, thermal dynamics, and mechanical engineering is essential to navigate the complexities of this process. The ability to control factors like heating time and temperature, cooling rates, and even the glass composition can significantly impact the final product's quality and safety standards.

Manufacturers must comply with rigorous industry standards and regulations. This ensures that the tempered glass meets necessary safety certifications, such as those from the American National Standards Institute (ANSI) and the European Committee for Standardization (CEN). These certifications are not mere formalities; they are a testament to the glass's ability to withstand stress and impact, making it suitable for critical applications.

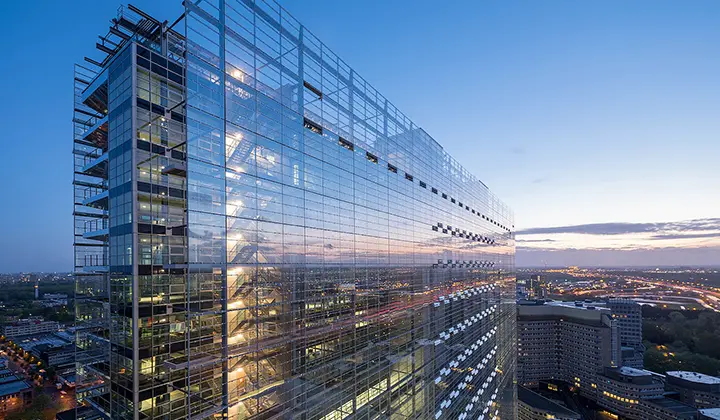

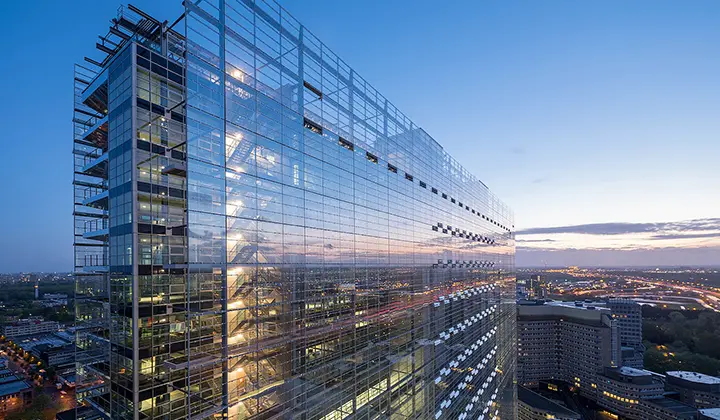

In the realm of material science, continual research and advancements have played a pivotal role in enhancing the quality of tempered glass. For example, the development of digital printing techniques allows manufacturers to imbue glass with decorative patterns without compromising its strength. This synergy of aesthetics and functionality has expanded tempered glass's use in interior design, making it a preferred choice for designers seeking both form and function.

manufacturing of tempered glass

Trustworthiness in the manufacturing of tempered glass is cultivated through transparency and a commitment to quality assurance. Manufacturers must invest in comprehensive testing procedures to ensure consistency and reliability. This includes stress testing under various environmental conditions and auditing every step of the production process. Establishing a traceable supply chain also adds to the credibility, assuring consumers that the glass they purchase is genuinely tempered and meets all safety requirements.

From an industry insider’s perspective, one challenge often faced by inexperienced manufacturers is the phenomenon known as 'spontaneous breakage.' This occurs due to the presence of nickel sulfide (NiS) inclusions in the glass. When these inclusions undergo transformation under temperature changes, they can lead to sudden glass failure. Addressing this requires both an in-depth understanding of the raw materials and employing advanced detection techniques, such as heat-soak testing, to mitigate risks.

The role of innovation cannot be understated in influencing the future of tempered glass manufacturing. As we push the boundaries of glass technology, embracing innovations like smart glass—which can change properties, such as shade or opacity, in response to electrical input—opens new avenues for tempered glass applications. These cutting-edge advancements not only enhance the functionality of the glass but also its market appeal.

In summary, the manufacturing of tempered glass is a sophisticated field that demands a blend of scientific know-how, meticulous adherence to regulatory benchmarks, and a relentless pursuit of quality and innovation. By focusing on these aspects, manufacturers can ensure their products remain at the forefront of the industry, providing safety, efficiency, and aesthetic appeal to a broad spectrum of applications. As a trusted entity in this domain, maintaining a reputation for reliability and excellence continues to be our guiding principle, enabling us to deliver products that stand the test of time and meet the ever-evolving demands of the modern world.

Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu