The Beauty and Functionality of Monolithic Annealed Glass

Monolithic annealed glass is a type of flat glass that has undergone a specific thermal treatment process, known as annealing, which enhances its physical properties and performance characteristics. This glass is widely used in various applications due to its aesthetic appeal, strength, and versatility. In this article, we will explore the manufacturing process, benefits, applications, and environmental impacts of monolithic annealed glass.

Manufacturing Process

The production of monolithic annealed glass begins with raw materials, primarily silica sand, soda ash, and limestone, combined in precise proportions. These ingredients are melted together in a furnace at high temperatures, around 1,700 to 2,000 degrees Celsius. The molten glass is then formed into sheets using the float glass process, where it is floated on molten tin to create a smooth surface.

Once the desired thickness and size are achieved, the glass sheets enter the annealing lehr, a controlled heating and cooling chamber. In the lehr, the glass is gradually cooled at a specific rate to relieve internal stresses. This annealing process is critical as it ensures uniformity in thickness and improves the structural integrity of the glass. The end result is a strong, flat, and clear sheet of glass that is ready for various applications.

Benefits of Monolithic Annealed Glass

One of the primary advantages of monolithic annealed glass is its aesthetic quality. The glass provides excellent clarity and optical quality, making it ideal for applications where visibility is paramount. Its smooth surface can easily be coated or tinted, offering additional customization options for architects and designers.

Furthermore, monolithic annealed glass is cost-effective compared to tempered or laminated glass products. The annealing process allows for mass production, resulting in lower production costs that can be passed on to consumers. This affordability makes it accessible for a wide range of projects, from residential to commercial buildings.

In terms of performance, while monolithic annealed glass is not as strong as tempered glass, it is sufficiently robust for many applications. It can withstand impacts and weather conditions, making it suitable for windows, glass doors, and interior partitions. Additionally, its excellent thermal insulation properties enhance energy efficiency in buildings, contributing to a reduction in energy consumption and cost savings over time.

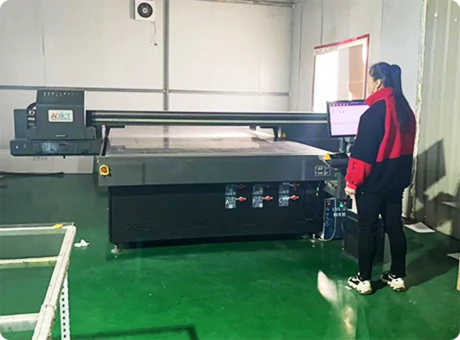

monolithic annealed glass

Applications

Monolithic annealed glass finds applications in various sectors, including construction, automotive, and interior design. In the construction industry, it is commonly used for windows, doors, glass facades, and partitions. The ability to produce large sheets also allows for expansive glass installations, providing a modern and open aesthetic to buildings.

In the automotive industry, monolithic annealed glass is utilized for windshield production and side windows. Its clarity and smooth finish ensure unobstructed visibility for drivers and passengers. Moreover, it can be fabricated to meet specific safety and regulatory standards, ensuring compliance without compromising on style.

Within interior design, monolithic annealed glass is often employed in furniture designs, such as tabletops and shelves, where elegance meets practicality. Its versatility also allows it to be used in artistic applications, like glass art installations and decorative panels that enhance interior aesthetics.

Environmental Impact

Despite its advantages, the environmental impact of monolithic annealed glass manufacturing cannot be overlooked. The glass production process is energy-intensive, contributing to greenhouse gas emissions. However, many manufacturers are now focusing on sustainable practices, such as using recycled glass and implementing energy-efficient technologies in production.

Recycling glass can significantly reduce the environmental footprint associated with its production, as it requires less energy than creating new glass from raw materials. Additionally, the durability and longevity of monolithic annealed glass contribute to its sustainability, as fewer replacements are needed over time.

Conclusion

Monolithic annealed glass is a remarkable material, seamlessly combining beauty, functionality, and affordability. Its extensive applications across various industries highlight its versatility and significance in modern design and architecture. As the demand for sustainable materials grows, the industry continues to evolve, striving towards greener solutions that benefit both consumers and the environment. Embracing monolithic annealed glass not only enhances the aesthetic appeal of spaces but also promotes a more sustainable future.

Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu