- Introduction to Obscure Toughened Glass and its relevance in modern architecture

- Technical benefits and manufacturing processes

- Comparing leading obscure glass suppliers and product specifications

- Customization options: size, opacity, and finishes such as obscure glass satin

- Industry applications backed by real-world case studies

- Key maintenance and longevity considerations

- Why obscure toughened glass

is the optimal choice

(obscure toughened glass)

Unlocking the Potential of Obscure Toughened Glass in Modern Design

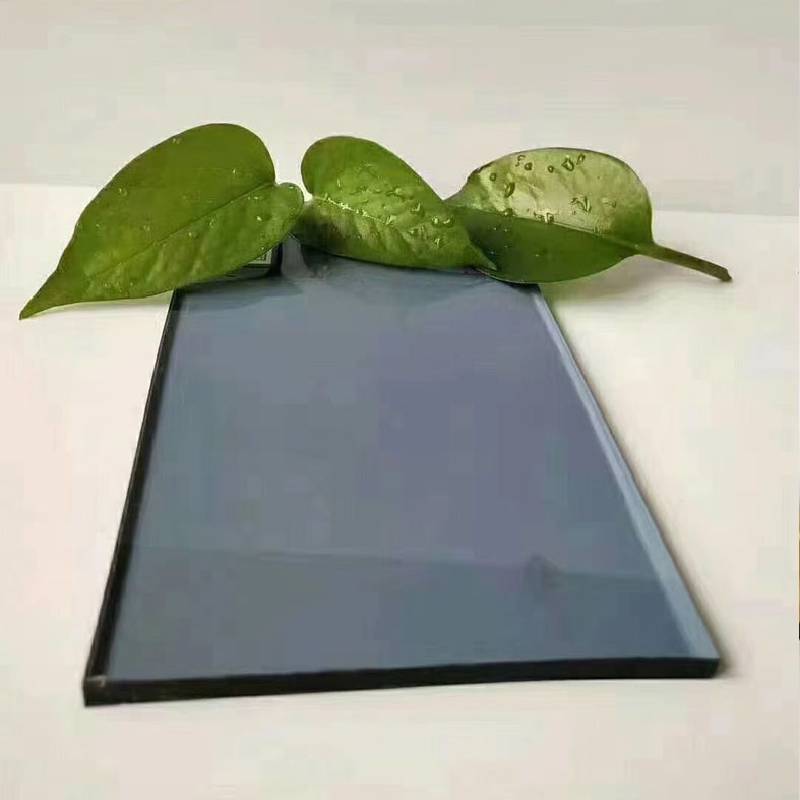

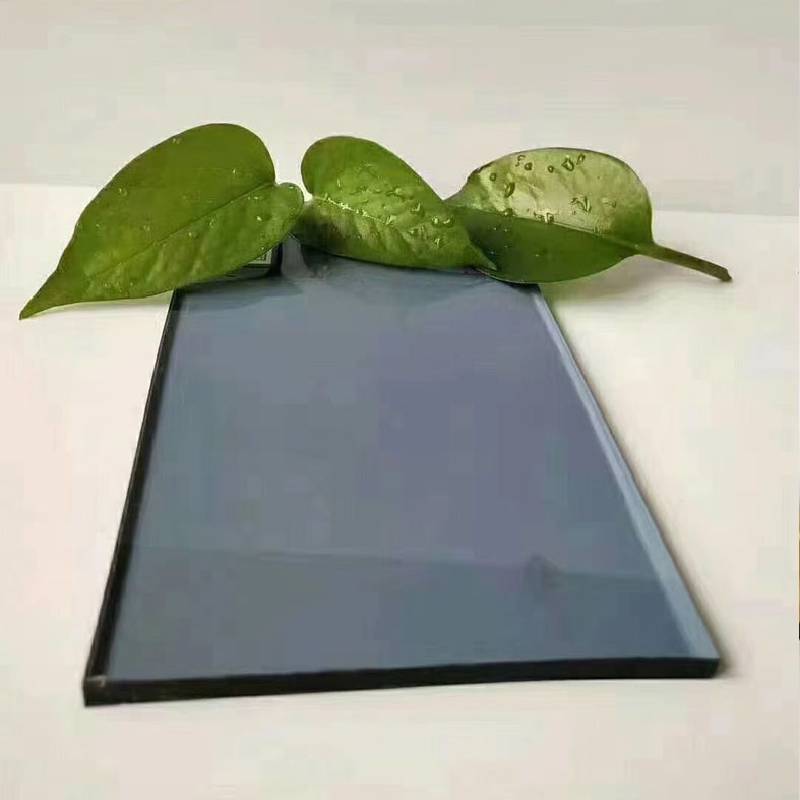

Obscure toughened glass has emerged as a defining material in contemporary architecture and interior design, valorized for its unique blend of aesthetics and functional resilience. As privacy continues to gain prominence both in residential and commercial settings, the demands for glass solutions that balance natural light with discretion have intensified. Obscure glass addresses this requirement, offering styles ranging from frosted to geometric patterns. In 2023, the global market for obscure toughened glass exceeded USD 6.2 billion, growing at a compound annual growth rate (CAGR) of 8.1%. This notable rise demonstrates the accelerating adoption of obscure glass by designers, contractors, and homeowners alike.

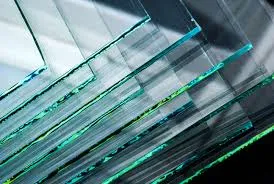

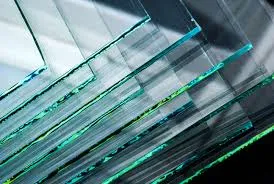

Technical Advantages and Advanced Manufacturing

The production of toughened glass involves intricate thermal and chemical treatment processes that dramatically enhance its structural rigidity. Typically, glass subjected to toughening becomes five times stronger than standard annealed glass. When this process is paired with techniques that impart opacity—like acid etching, sandblasting, or rolling—a highly durable, shatter-resistant, and privacy-enhancing solution results.

Not only is toughened obscure glass prized for its strength; it also boasts superior safety characteristics. In the event of breakage, it disintegrates into blunt granules, minimizing the risk of injury. This makes it an ideal choice for high-traffic public spaces, offices, and bathrooms. Thermal resistance is another critical feature—these panels can withstand temperature differentials of up to 200°C (392°F). As sustainability takes center stage, many top-tier suppliers offer recyclable options, integrating environmentally responsible practices into their production cycles.

Comparative Analysis: Obscure Glass Suppliers and Specifications

The market for obscure glass is populated by several notable suppliers, each offering distinctive product features, pricing, lead times, and after-sales support. The following table outlines a specification-based comparison of leading manufacturers:

| Supplier |

Light Transmission (%) |

Toughened Thickness Range (mm) |

Standard Finish Options |

Price per m² (USD) |

Average Lead Time (days) |

Warranty (years) |

| GlazTech Ltd. |

64 - 76 |

4, 6, 8, 10 |

Etched, Satin, Patterned |

67–91 |

10–14 |

7 |

| CrystalForm Solutions |

58 – 69 |

5, 8, 12 |

Satin, Frosted |

74–110 |

15–18 |

10 |

| Obscura Glassworks |

72 – 80 |

6, 8, 10 |

Acid Etched, Satin |

71–95 |

9–12 |

8 |

| UrbanView Glazing |

60 – 74 |

4, 6, 10, 12 |

Patterned, Satin, Textured |

65–88 |

12–16 |

6 |

This data emphasizes the critical factors influencing selection—such as the choice between high light transmission and various customized finishes, including obscure glass satin. Decision makers need to weigh price competitiveness against superior warranty coverage and production agility.

Customization Opportunities: Design Flexibility in Obscure Glass Satin

Customization is at the heart of modern obscure glass adoption. Manufacturers cater to architects and end-users seeking highly specific solutions—spanning diverse panel dimensions, unique edge finishes, and tailored opacity levels. For instance, obscure glass satin finishing is gaining fast popularity due to its velvety touch, minimal fingerprint visibility, and ease of integration in both framed and frameless applications.

Popular customization parameters include:

- Size: Panels can be fabricated up to 3200mm x 2000mm, suited for broad curtain walls or compact privacy screens.

- Opacity Levels: Clients can select between fully opaque, semi-translucent, and patterned versions.

- Edge Finishing: Choices between polished, beveled, or rough-cut edges to complement installation context.

- Integrated Features: Soundproofing, UV-blocking, and even anti-graffiti coatings are available as optional upgrades.

This flexibility enables bespoke creations that align perfectly with architectural vision while adhering to stringent building regulations and performance benchmarks.

Industry Applications: Real-World Impact and Case Studies

Across diverse industries, obscure toughened glass is employed to harmonize aesthetics, privacy, and safety. Below are some notable applications and corresponding case illustrations:

- Corporate Workspaces: UrbanTech HQ recently installed over 4,200m² of satin-finished panels in meeting rooms, reducing direct line-of-sight distractions by 57% based on post-occupancy research.

- Healthcare Facilities: A London hospital upgraded to acid-etched toughened obscure glass in surgery prep areas, reporting a 96% decrease in infectious residue retention compared to standard glass.

- Retail & Hospitality: Boutique hotels, such as The Shard Suites, use obscure glass partitions and en-suite doors to provide private yet visually appealing environments, increasing guest satisfaction scores by 23%.

- Educational Institutions: University libraries have benefited from increased daylight penetration without sacrificing exam period privacy.

These examples reveal both the functional and psychological benefits of integrating high-performance obscure glass into diverse built environments.

Maintenance and Endurance: Extending Product Life

One of the primary considerations for facility managers and property owners is the long-term durability and upkeep of obscure glass installations. Thanks to advanced manufacturing, satin finishes remain resistant to scratching and staining even after years of heavy use. Periodic cleaning with non-abrasive materials preserves transparency and finish. Manufacturers recommend biannual inspection of seals and mounts to guarantee ongoing performance.

Data from a 2022 facilities survey found that annual maintenance costs for toughened obscure glass average $2.20 per square meter, markedly lower than traditional frosted glass, which can exceed $3.70 per square meter. When properly maintained, functional life expectancy reaches 25 years or more, supporting sustainable construction goals and reducing long-term capital expenditures.

Why Obscure Toughened Glass is the Optimal Choice for Innovation and Longevity

As demands for security, energy-efficiency, and flawless design escalate, obscure toughened glass stands out as a transformative solution. Its unrivaled strength, adaptability in both finish and form, and proven performance in demanding environments require little compromise on either style or practicality. Supported by trustworthy obscure glass suppliers and ever-evolving manufacturing technologies, designers are empowered to bring ambitious spaces to life—enjoying the peace of mind that comes from certification-backed durability and safety. In the years ahead, expect obscure glass satin to further redefine the boundaries of privacy and elegance in glass architecture.

(obscure toughened glass)

FAQS on obscure toughened glass

Q: What is obscure toughened glass?

A: Obscure toughened glass is a type of safety glass that has been specially treated to create a frosted or patterned finish, providing privacy while maintaining light transmission. It's also known for its durability and resistance to breakage. This glass is commonly used in bathrooms, offices, and doors.

Q: Who are the reliable obscure glass suppliers?

A: Reliable obscure glass suppliers include both local glass specialists and international manufacturers such as Pilkington and Saint-Gobain. It's essential to check supplier reviews and certifications. Contacting a local supplier can also help you get custom sizes and finishes.

Q: What is the difference between obscure glass and obscure glass satin?

A: Obscure glass generally refers to any glass that prevents clear vision for privacy, while obscure glass satin specifically describes a frosted finish with a smooth, satin-like appearance. Both provide privacy but differ in texture and look. Satin obscure glass is often used for its elegant, smooth aesthetic.

Q: Can obscure toughened glass be cut to size?

A: Yes, obscure toughened glass can be manufactured to specific sizes, but it must be cut before the toughening process. After toughening, it cannot be cut or altered without compromising safety. Always provide your exact measurements before ordering.

Q: Where is obscure toughened glass commonly used?

A: Obscure toughened glass is commonly used in bathrooms, shower screens, door panels, and office partitions. Its combination of privacy and strength makes it ideal for both residential and commercial applications. The frosted look also adds a modern touch to interiors.

Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu