Understanding Plain Float Glass Properties, Production, and Applications

Plain float glass is a widely used material in various industries, known for its clarity, brightness, and thermal stability. This article explores the properties, production techniques, and diverse applications of plain float glass, emphasizing its significance in modern construction and design.

Properties of Plain Float Glass

Plain float glass is characterized by a few key properties that make it an excellent choice for numerous applications. Firstly, it is made from high-purity silica sand, soda ash, and limestone, which are melted together at high temperatures. The resulting product is a flat sheet of glass with a uniform thickness and smooth surface, allowing for high light transmission and minimal distortion.

Another significant property of plain float glass is its optical clarity. The glass is produced through a process that creates an optical quality surface, making it ideal for applications where visibility is essential, such as windows and display cases. Additionally, plain float glass is resistant to many chemical agents, which enhances its durability and longevity.

Thermal performance is another crucial aspect to consider. While plain float glass is not a thermal insulator, it can withstand significant temperature changes without breaking, making it suitable for environments where such conditions are common. Its ability to reflect and transmit light also provides advantages in energy-efficient building design.

Production of Plain Float Glass

The production of plain float glass involves several steps, starting with the preparation of raw materials

. The primary ingredients—silica sand, soda ash, and limestone—are combined and heated in a furnace at temperatures exceeding 1,600 degrees Celsius (2,912 degrees Fahrenheit). The molten glass is then floated on a layer of molten tin, which creates a perfectly flat surface.

This floating process is critical because it minimizes surface defects and ensures a uniform thickness. After forming, the glass is gradually cooled in a controlled manner, known as annealing, to relieve internal stresses. The resulting sheets are then cut to size, polished, and packaged for distribution.

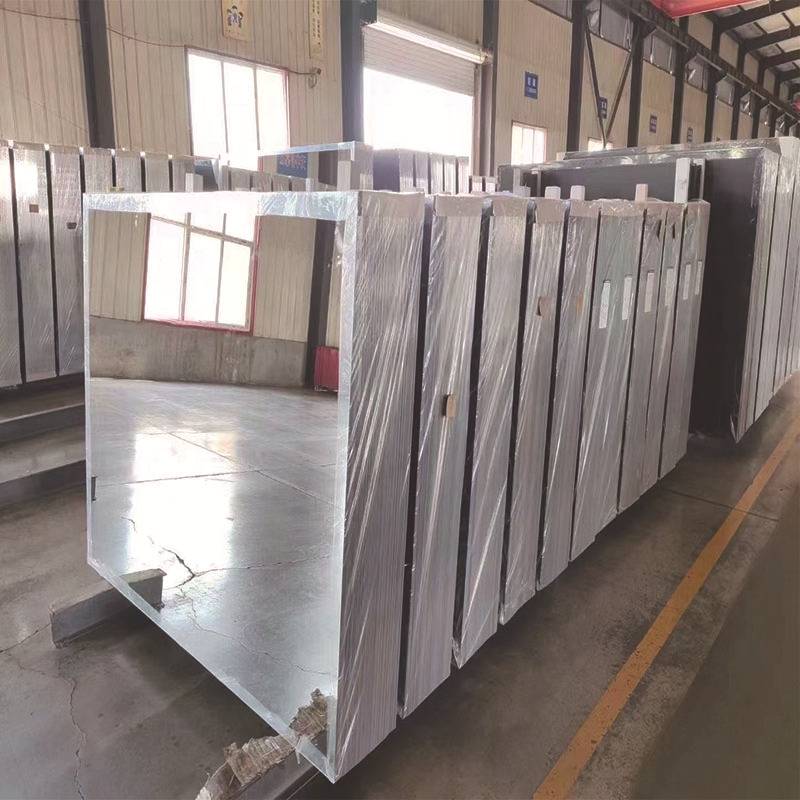

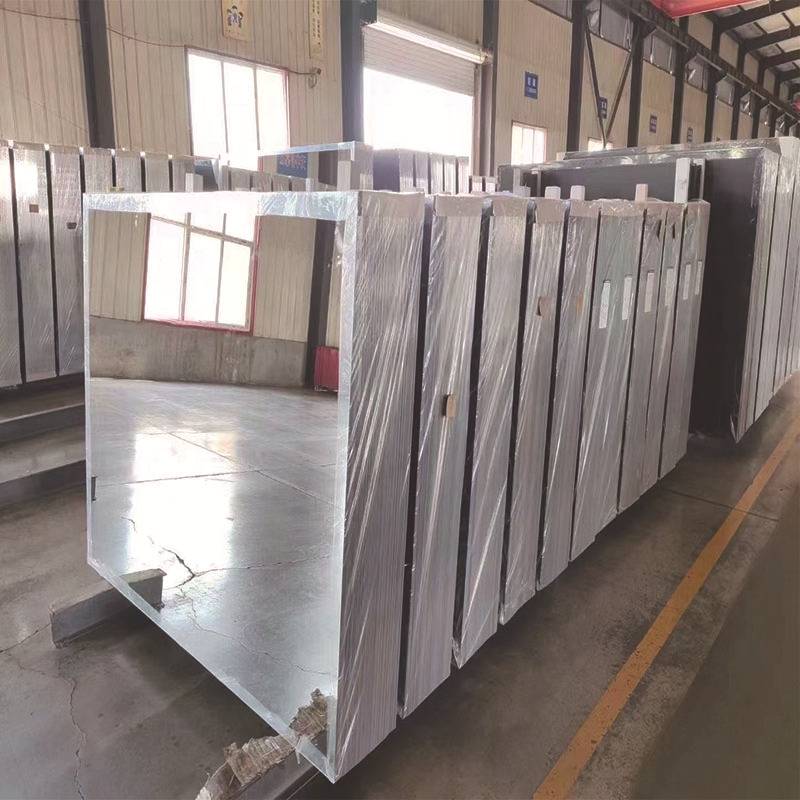

plain float glass

This innovative production method was first developed in the mid-20th century and has since evolved with technological advancements. Modern float glass production facilities utilize automated systems for better efficiency and quality control, making it one of the most reliable and popular glass types available.

Applications of Plain Float Glass

The versatility of plain float glass makes it suitable for a wide range of applications. In the construction industry, it is predominantly used for windows in residential and commercial buildings due to its excellent light transmission and aesthetic appeal. Architects often choose plain float glass for façades to create a seamless connection between indoor and outdoor spaces.

Moreover, plain float glass serves various functional roles in buildings, including doors, partitions, and skylights. Its ability to be easily fabricated allows for customization, enabling designers to create unique architectural features while adhering to safety standards.

In the automotive industry, plain float glass is commonly used for windshields and windows. Its clarity and strength enhance driver visibility and safety. Additionally, it is used in manufacturing appliances and interior design elements such as tabletops and mirrors, where aesthetics are paramount.

Furthermore, float glass has applications in the energy sector, specifically in solar panel technology. By effectively transmitting sunlight, plain float glass helps maximize energy capture in photovoltaic solar panels, contributing to sustainable energy solutions.

Conclusion

In summary, plain float glass is an essential material at the intersection of functionality and aesthetics. Its unique properties, efficient production process, and versatile applications have made it a staple in construction, automotive, and energy sectors. As technology continues to advance, the potential for new uses and enhancements of plain float glass remains vast, ensuring its relevance in future developments. Whether used in modern skyscrapers or innovative solar technologies, plain float glass will undoubtedly continue to play a vital role in shaping our environments.

Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu