The Plate Glass Manufacturing Industry An Overview

The plate glass manufacturing industry is a crucial sector that contributes significantly to the economy and modern architecture. Plate glass, known for its flatness and clarity, is primarily used in windows, doors, skylights, and various architectural applications. This article explores the processes involved in plate glass production, the key players in the industry, and the trends shaping its future.

The Manufacturing Process

The production of plate glass involves several stages, beginning with the raw materials. The primary components include silica sand, soda ash, and limestone. These materials are combined in specific proportions to form a batch that will be melted at high temperatures. The melting process occurs in a furnace, where the mixture is heated to around 1,500 degrees Celsius (approximately 2,732 degrees Fahrenheit). This high-temperature environment ensures that the raw materials fuse together to create molten glass.

Once melted, the glass is refined and homogenized to eliminate bubbles and impurities. The next step is forming the glass into flat sheets. This is usually achieved through two primary processes the float glass process and the casting process. The float glass method, which is the most commonly used today, involves pouring the molten glass onto a pool of molten tin, creating a smooth and uniform surface. In contrast, the casting process involves pouring molten glass into molds to create specific shapes or sizes, which is generally used for thicker glass products.

After forming, the glass sheets undergo annealing in a controlled cooling environment, which helps to relieve internal stresses and ensure durability. Finally, the glass is cut to size, polished, and treated as necessary for its intended use.

Key Players in the Industry

The plate glass manufacturing industry comprises several major companies that dominate the market. Firms like Saint-Gobain, Guardian Glass, and Pilkington are well-known for their high-quality products and innovative technologies. These manufacturers focus on developing energy-efficient and sustainable glass solutions to meet the growing demand from the construction industry.

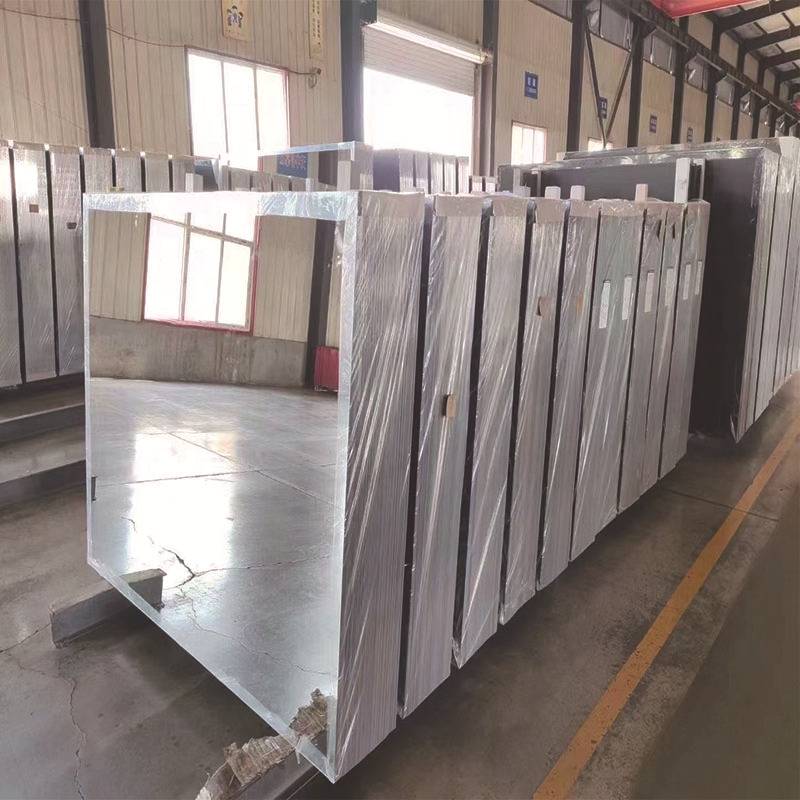

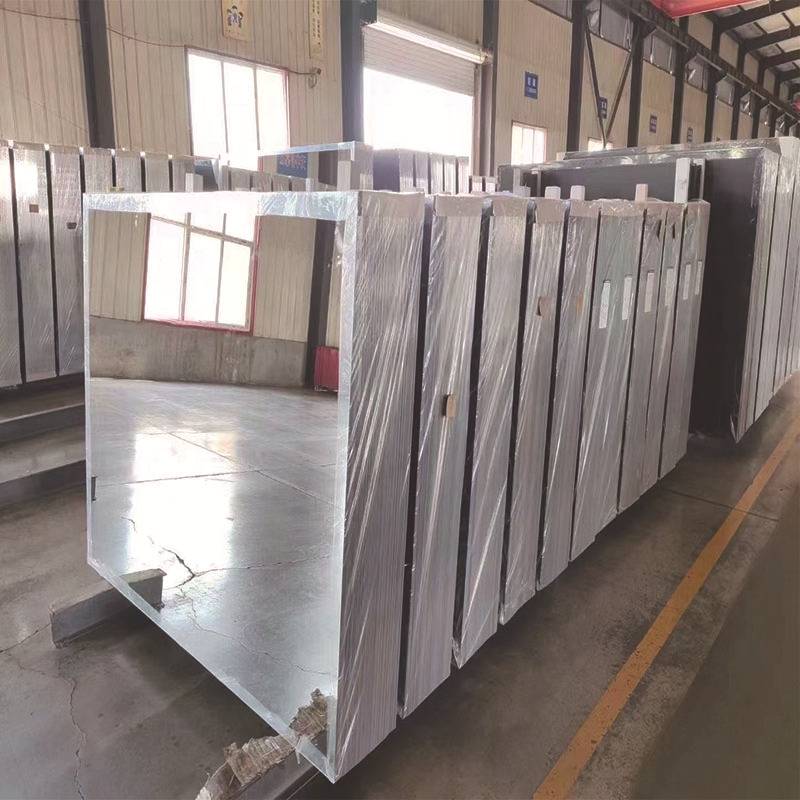

plate glass manufacturers

Additionally, the rise of small and medium enterprises (SMEs) in various regions has contributed to the diversification of the market. These companies often specialize in niche markets, such as custom-sized glass or specialized coatings, allowing them to compete with larger firms effectively.

Trends and Future Outlook

Several trends are currently shaping the plate glass manufacturing sector. One significant trend is the increasing demand for energy-efficient glass products, driven by global initiatives aimed at reducing energy consumption in buildings. Low-emissivity (Low-E) glass, which reflects heat while allowing light to enter, has gained popularity in both residential and commercial applications.

Environmental sustainability is another critical focus for manufacturers. Companies are investing in recycling technologies to reduce waste and improve resource efficiency. Moreover, the use of eco-friendly raw materials and processes is becoming more prevalent, aligning with global efforts to combat climate change.

Technological advancements also play a significant role in the industry’s evolution. Innovations such as smart glass, which can change its properties based on environmental conditions, are gaining traction. These products not only enhance energy efficiency but also add aesthetic value to architectural designs.

Conclusion

The plate glass manufacturing industry is a dynamic and essential component of modern construction and design. As it continues to evolve, driven by technological advancements and sustainability demands, manufacturers must stay ahead of the curve to meet the changing needs of consumers and the environment. The future of plate glass looks bright, with opportunities for growth and innovation on the horizon.

Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu