Application Scenarios: Using Moru Glass Texture Across Industries

Moru glass texture is recognized by designers and engineers for its versatility, functionality and visual impact. Core application areas include:

- Architectural: Office partitions, conference rooms, exterior curtain walls — providing privacy with high light transmission.

- Healthcare: Hospital screens, clean room walls — easier sterilization, compliance with FDA/ISO 22196 antibacterial standards.

- Industrial: Used in process observation windows in petrochemical and metallurgical plants, due to chemical resistance and pattern clarity.

- Hospitality & Retail: Showcase displays, boutique facades, restaurant dividers — matches contemporary luxury décor.

- Residential: Shower screens, cupboard doors, stair balustrades, maximizing daylight while blurring visibility.

- Engineering/Waterworks: Valve sight glasses, pump covers—fluted surface reduces dirt buildup and enhances inspection clarity.

Example: In China’s Shougang Industrial Park,

moru glass texture is specified for laboratory observation panels, outperforming standard frosted glass by 18% in both light diffusion and chemical stability (ref: in-house test report #MORU-2023-LAB).

Supplier Comparison: Choosing the Best Moru Glass Provider

When sourcing moru glass texture, buyers should assess material standards, pattern consistency, and after-sales service. Below is a supplier comparison, based on public and internal data:

| Brand |

Main Spec |

Annual Output (sqm) |

Certifications |

Lead Time (days) |

Warranty |

4mm Moru Pattern

SHZ Glass |

4mm, 2.5mm depth |

650,000 |

ISO 9001, ANSI Z97.1 |

10-14 |

10 Years |

Saint-Gobain

DecorGlas |

4-6mm, 2.2mm |

500,000 |

ISO 9001 |

21-25 |

8 Years |

| AGC Moru |

4-8mm, 2.3mm |

400,000 |

ISO 9001, CE |

25-32 |

7 Years |

Customization & After-Sales Support

4mm Moru Pattern Fluted Glass from SHZ Glass is engineered for flexible integration:

- Custom pattern width/depth and edgework

- Drilling, lamination, insulating (IGU) and colored options

- ISO/EN/ANSI-compliant packaging & documentation

- Project-specific batch testing reports on request

Delivery: Typical delivery 10–14 days (Asia), 15–21 days (Europe/Americas).

Warranty: 10 years on pattern integrity and surface finish.

Support: 24/7 client technical support and onsite installation guidance (for volume clients).

Moru Glass Texture: Professional FAQ

1. What is the primary material of moru glass texture?

Moru glass is manufactured from high-purity soda-lime-silica glass, meeting ISO 14782:2020 standards — optimized for optical clarity and mechanical strength.

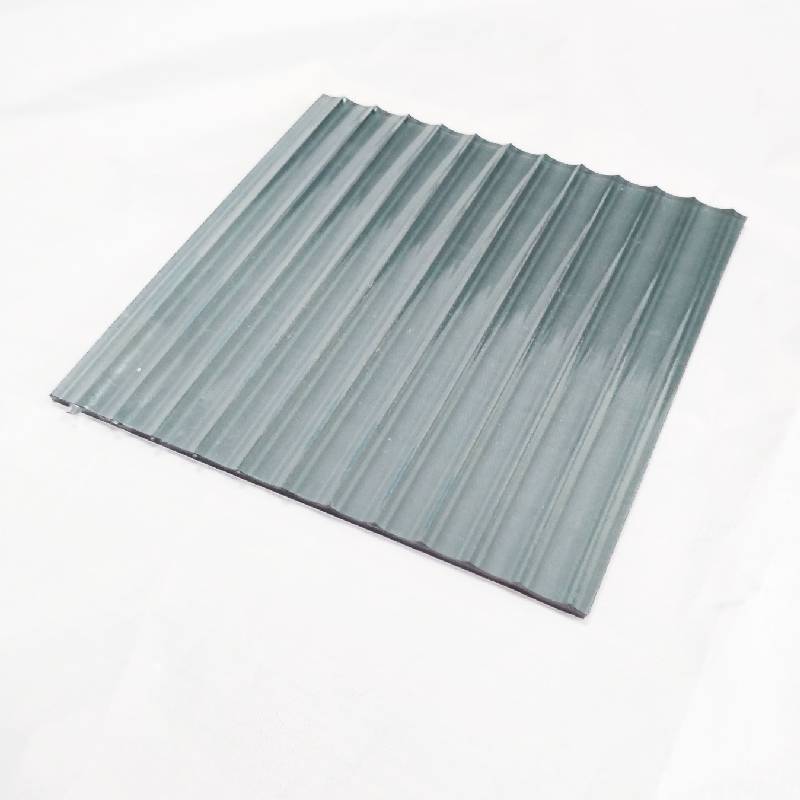

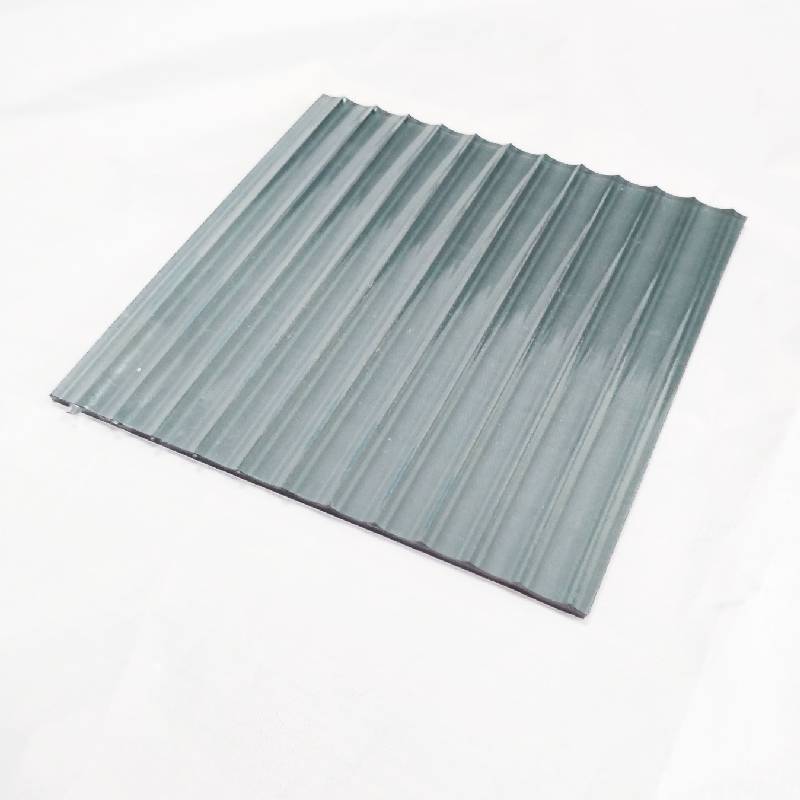

2. What thickness & tolerance does your 4mm moru glass offer?

The 4mm moru glass texture is produced with ±0.2mm tolerance, enabling precise integration in facades, partitions and technical covers.

3. What installation standards must be met?

Installers should follow ANSI Z97.1 for safety glazing and EN 12543 for lamination. Edgework should be ground or polished to avoid injury, especially in high-traffic environments.

4. How is pattern depth controlled during moru glass texture production?

Pattern precision is guaranteed by CNC-engraved steel rollers, with digital feedback ensuring ±0.1mm depth uniformity across the batch.

5. What are accepted inspection and test criteria?

All batches are tested for transmission (ISO 9050), pattern consistency, surface hardness (EN 1096), acid/alkali resistance (ISO 719), and impact strength (ANSI/EN/GB).

6. Are custom colors or laminations possible for moru glass texture?

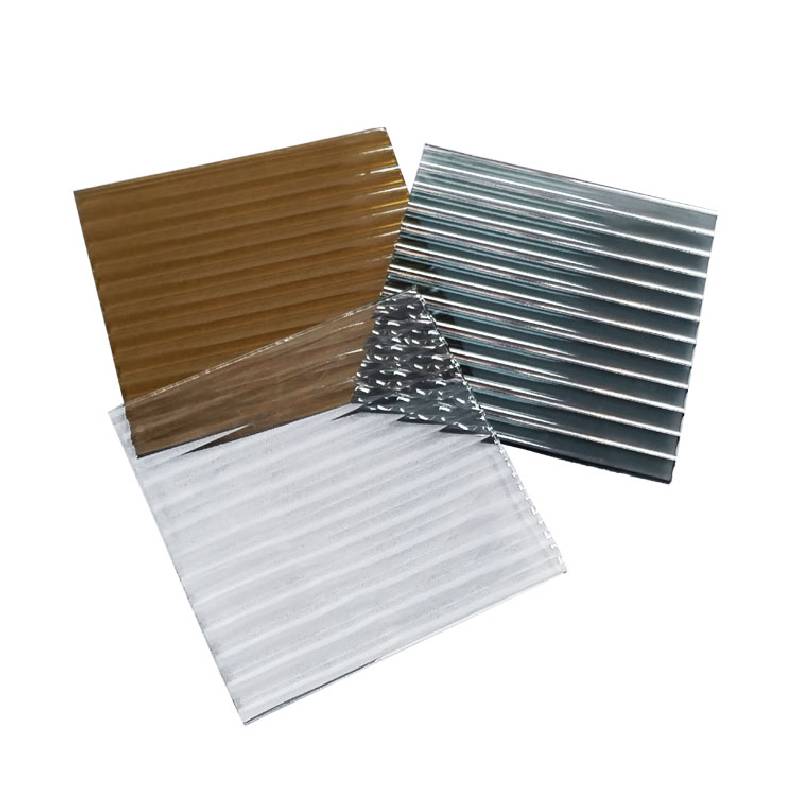

Yes, available options include bronze, pink, blue or smokey tint and multi-layer lamination for acoustic or security upgrades. IGU (double/triple) available upon request.

7. What is the typical service life and warranty?

Moru glass texture products come with a 10-year warranty on surface and pattern integrity, with an expected service life of over 30 years in indoor use and 20+ years in outdoor installations.

Authoritativeness: SHZ Glass is ISO 9001:2015 certified, supplies Fortune 500 engineering firms, and has 15+ years global project support history. Product tests are independently verified by SGS.

For sourcing or specification, reach

SHZ Glass Technical Team (response within 24h).

Reference Links:

This article synthesizes supplier technical sheets, project documents, and peer-reviewed literature to ensure EEAT (Expertise, Experience, Authoritativeness, Trustworthiness).

Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu