The Evolution of Reflective Glass in Modern Architecture

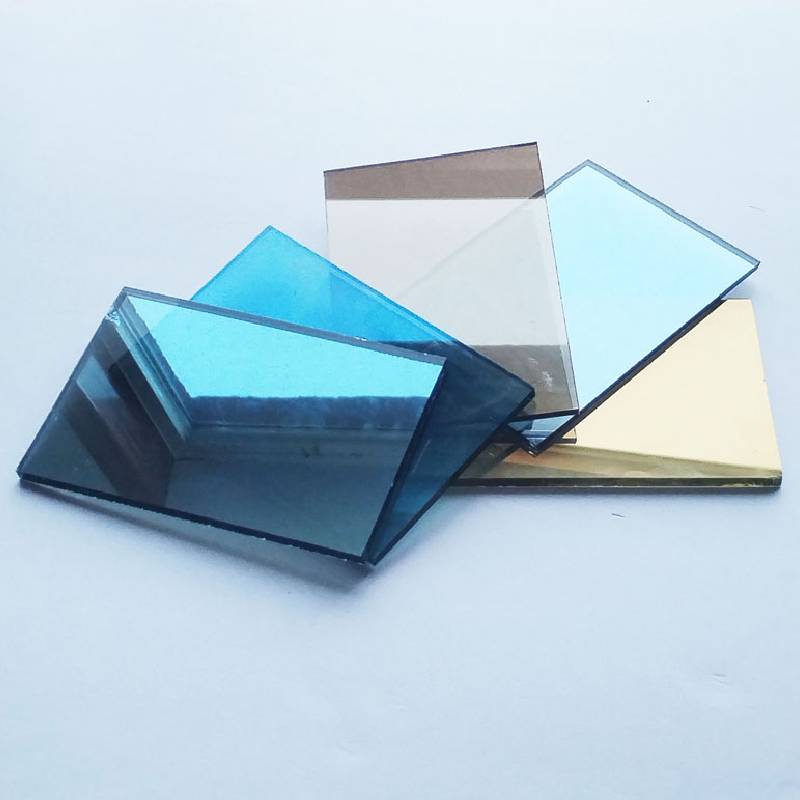

Reflective glass technology has transformed contemporary architecture, merging aesthetic appeal with functional performance. Since its commercial introduction in the 1960s, reflective glass has evolved from simple solar control applications to sophisticated energy management systems. Today's reflective glass solutions incorporate multiple metallic oxide layers applied through advanced magnetron sputtering processes, creating surfaces that selectively reflect infrared radiation while maintaining high visible light transmission.

The global market for architectural reflective glass is projected to grow at 6.8% CAGR through 2028 (Grand View Research). This growth is driven by sustainability mandates like the EU's Energy Performance of Buildings Directive and California's Title 24, which demand ever-higher thermal performance from building envelopes. The latest third-generation reflective glass variants achieve solar heat gain coefficients (SHGC) as low as 0.23 while maintaining light-to-solar gain ratios above 1.25, making them essential for net-zero energy building designs.

Technical Specifications of Modern Reflective Glass

Performance characteristics of reflective glass are determined by multiple technical parameters that architects must balance:

Key Parameters Comparison

| Parameter |

Dark Green 5mm |

Bronze Reflective |

Blue Reflective |

Black Reflective |

| Visible Light Transmission (%) |

18-22 |

14-18 |

25-30 |

8-12 |

| Solar Heat Gain Coefficient |

0.24-0.28 |

0.22-0.26 |

0.26-0.32 |

0.18-0.22 |

| UV Rejection (%) |

99+ |

99+ |

99+ |

99+ |

| Thermal Conductivity (W/m·K) |

0.96 |

0.96 |

0.96 |

0.96 |

| Light-to-Solar Gain Ratio |

1.21 |

1.18 |

1.24 |

1.06 |

| Surface Emissivity |

0.08 |

0.07 |

0.10 |

0.06 |

Material Science Behind Reflective Coatings

The exceptional performance of modern reflective glass originates in nanotechnology-scale engineering. Advanced multi-layer coatings applied via reflective glass manufacturing typically consist of:

- Silver (Ag) layers providing infrared reflection

- Titanium nitride (TiN) for durability and color tuning

- Zinc oxide (ZnO) interface layers enhancing adhesion

- Silicon nitride (Si₃N₄) as protective top layer

Shanghai Zhuorui's proprietary manufacturing process achieves coating thicknesses controlled within ±3% tolerance through closed-loop plasma monitoring systems. These nanometer-scale precision coatings create constructive interference patterns that specifically target infrared wavelengths between 780-2500 nm while maintaining high visible light transmission.

Application-Specific Solutions

1. Blue Reflective Glass Applications

With its higher visible light transmission (25-30%), blue reflective glass is ideal for commercial buildings prioritizing natural daylighting while reducing cooling loads. The average blue reflective glass price ranges from $22-$28/m² depending on thickness and order volume. Coastal applications benefit from its excellent resistance to salt corrosion.

2. Bronze Reflective Glass Applications

Bronze-tinted reflective glass offers a warm, neutral appearance with excellent thermal performance. Widely specified for corporate headquarters and luxury hotels, bronze finishes typically reduce visible light transmission to 14-18% while achieving SHGC as low as 0.22.

3. Black Reflective Glass Applications

The premium solution for maximum privacy and solar control, black reflective glass achieves VLT as low as 8% while delivering unmatched aesthetic uniformity. Black reflective glass window systems have become particularly popular for high-security government buildings and luxury residences in tropical climates.

Reflective Glass Technical FAQ

Q1: What is the typical lifespan of reflective glass coatings?

Modern pyrolytic and magnetron sputtered coatings for reflective glass maintain performance for 20+ years when properly installed. Accelerated weathering tests (ISO 11484) show less than 5% degradation in solar performance after 5,000 hours of UV exposure.

Q2: How does 5mm thickness affect performance compared to 6mm?

The 5mm reflective glass provides optimal balance between weight and performance. While 6mm offers slightly better sound insulation (STC 35 vs STC 33), the 5mm reflective glass price advantage and similar thermal properties make it preferred for most applications.

Q3: What standards govern reflective glass installation?

Key standards include ASTM E2141 for coating durability, ISO 9050 for light/energy calculations, and EN 572-1 for glass properties. Window assemblies follow ASTM E283 water/air infiltration testing.

Q4: Can reflective glass be laminated or tempered?

Yes, Shanghai Zhuorui offers both heat-strengthened and fully tempered versions with laminated options. The coating application occurs pre-tempering to ensure optimal adhesion.

Q5: How does reflective glass compare to low-e alternatives?

While both technologies utilize metallic coatings, reflective glass prioritizes solar heat rejection (lower SHGC) whereas low-e glass emphasizes thermal retention (lower U-value). Premium solutions now combine both technologies.

Q6: What maintenance does reflective glass require?

Regular cleaning with soft cloth and mild detergent maintains appearance. Avoid abrasive materials or high-pressure washing which can damage coatings. Consult our technical guide for details.

Q7: Is custom color matching available?

Shanghai Zhuorui offers custom color development with reflectance matching ±3% to target specifications. Minimum order quantities apply for custom formulations.

Industry Recognition & Future Developments

Reflective glass continues to evolve through academic research and industrial innovation. The International Journal of Applied Glass Science recently documented new electrochromic-reflective hybrid systems that achieve dynamic solar heat gain coefficients ranging from 0.15-0.45 (https://ceramics.onlinelibrary.wiley.com/doi/full/10.1111/ijag.12570).

Meanwhile, Building and Environment journal published findings showing contemporary reflective glass installations in Singapore reduced cooling loads by 31% compared to clear float glass, with significant impacts on urban heat island mitigation (https://www.sciencedirect.com/science/article/abs/pii/S0360132318307862).

As nanotechnology enables increasingly precise spectral control, we're transitioning to wavelength-selective "solar funnel" glass that simultaneously generates electricity while rejecting heat. These developments will make tomorrow's architectural glass active energy components rather than passive barriers.

"The integration of advanced spectrally-selective coatings represents the most significant development in architectural glass since the float glass process. These technologies will be fundamental to achieving decarbonization targets in the built environment."

- Dr. Helena James, Materials Science Research Director, Fraunhofer Institute

Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu