The Process of Making Tempered Glass

Tempered glass, also known as toughened glass, is a type of safety glass that undergoes a specific heat treatment process to enhance its strength and durability. The process of making tempered glass involves several critical steps, each contributing to the final product's ability to withstand high temperatures and impacts.

The journey begins with selecting the right raw materials. High-quality glass is preferred to ensure optimal results. Once the raw glass is prepared, it is cut to the desired dimensions. Precision is key in this stage, as any defects may affect the safety and performance of the tempered glass.

After cutting, the glass is subjected to a rigorous washing process. It is essential to remove any dirt, oil, or impurities that could interfere with the subsequent thermal treatment. This washing process typically involves a combination of detergents and rinsing with high-purity water, ensuring that the surface of the glass is pristine.

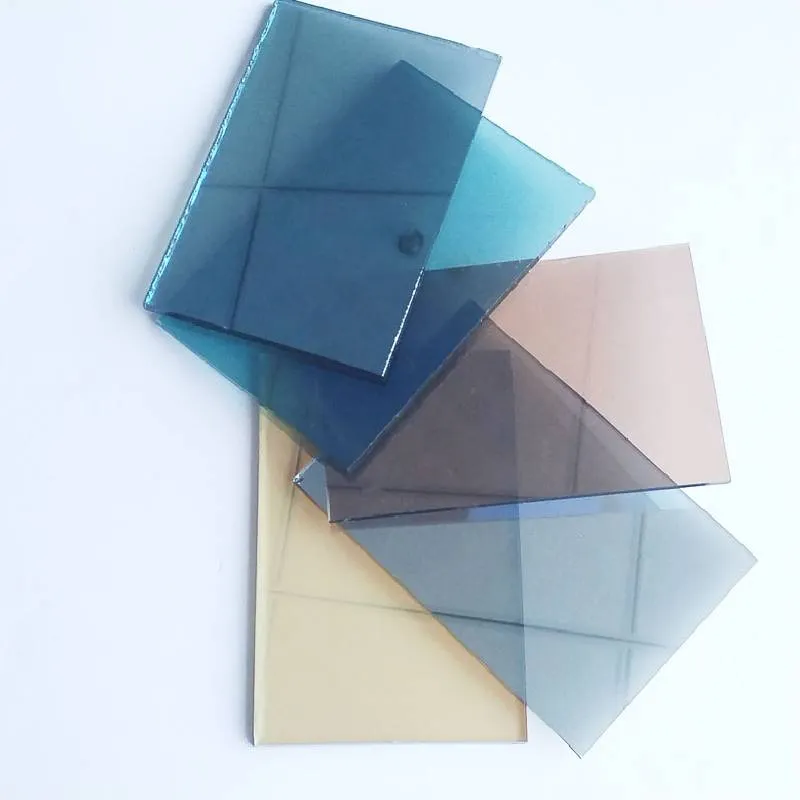

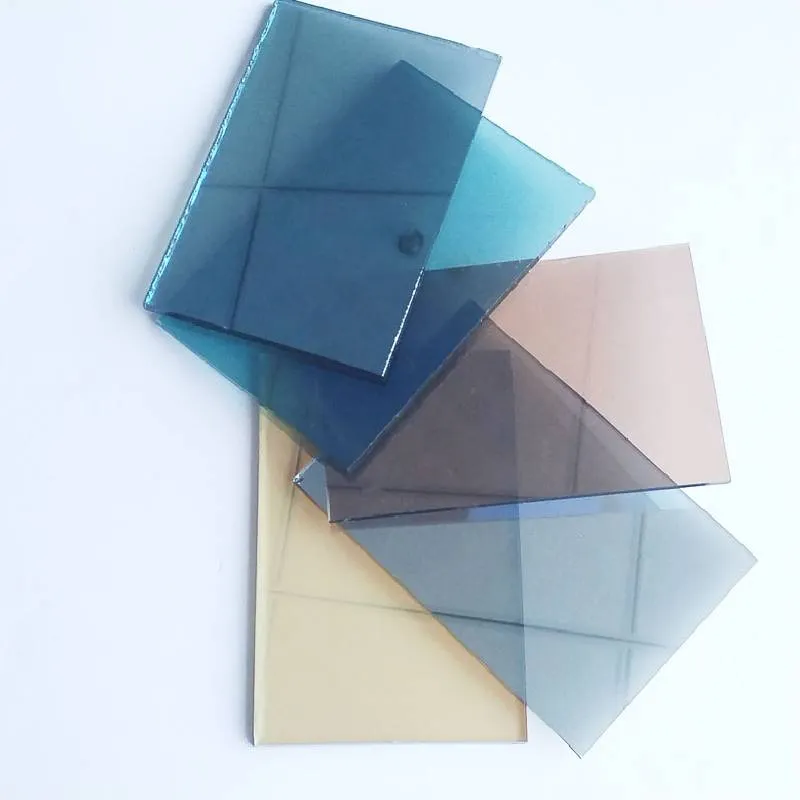

process of making tempered glass

Following the cleaning, the glass is placed in an oven, where it is heated to temperatures between 600 to 700 degrees Celsius (about 1112 to 1292 degrees Fahrenheit). This heating process is known as annealing, and it allows the glass to reach a uniform temperature. Maintaining this temperature for a sufficient period is crucial, as it ensures that the internal structure of the glass becomes more malleable, preparing it for the next stage.

Once the glass has reached the desired temperature, it is rapidly cooled in a process called quenching. This involves passing cool air over the surface of the glass, allowing the outer layers to cool significantly faster than the inner layers. The rapid temperature change creates a compressive stress on the surface of the glass, which enhances its strength. As a result, tempered glass is about five to six times stronger than standard glass of the same thickness.

Finally, after the glass is tempered, it undergoes rigorous quality control. This step ensures that the glass meets safety standards and specifications, checking for any visual defects such as bubbles or distortions. Once it passes inspection, the tempered glass is ready for use in various applications, including windows, shower doors, glass doors, and facades.

In conclusion, the process of making tempered glass is a complex yet fascinating procedure that transforms ordinary glass into a robust material. Through careful selection of materials, precise cutting and heating, and rapid cooling, manufacturers create a product that enhances safety and performance in everyday applications.

Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu