The Art and Science of Sheet Glass Manufacturing

Sheet glass manufacturing is a remarkable blend of art and science that plays a pivotal role in various industries. From architecture to automobiles, sheet glass serves as an essential material that offers clarity and strength. The process of creating this versatile material involves several intricate steps and advanced technologies.

The journey of sheet glass begins with the selection of raw materials. The primary ingredients used in manufacturing sheet glass include silica sand, soda ash, and limestone. Silica sand provides the essential silica component, which is the primary building block of glass. Soda ash acts as a flux, lowering the melting point of silica, while limestone helps to stabilize the glass structure. The right proportions of these materials are crucial to ensure the desired quality and properties of the final product.

The Art and Science of Sheet Glass Manufacturing

After reaching a uniform state, the molten glass is shaped into sheets through various processes. One of the most common methods is the float glass process, which involves pouring the molten glass onto a pool of molten tin. This method allows the glass to spread evenly, creating a flat and smooth surface. The use of tin helps in achieving a perfect finish since it prevents the glass from sticking. As the glass cools, it solidifies, forming a continuous sheet.

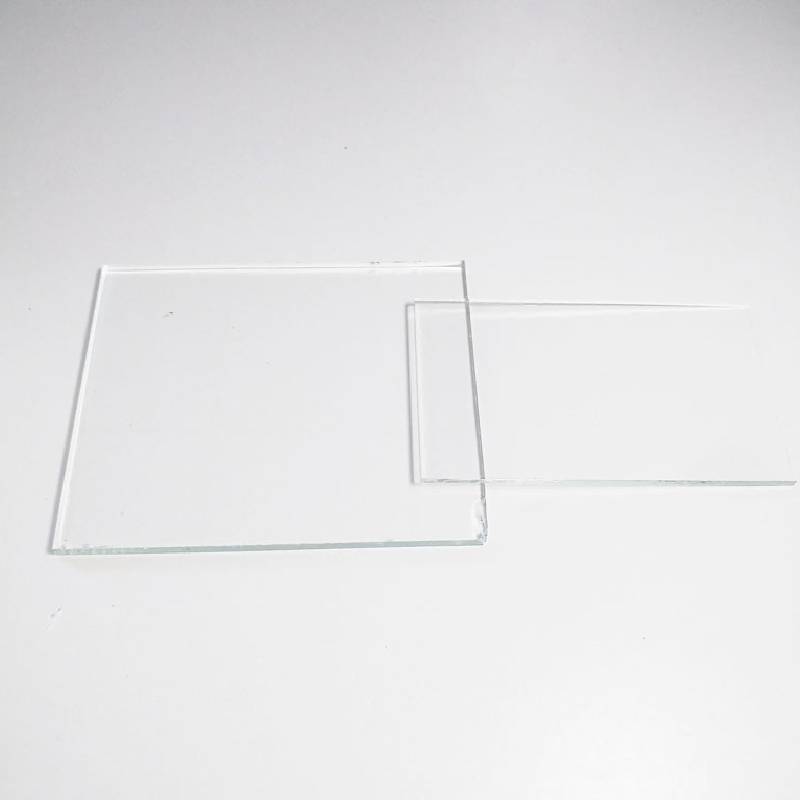

sheet glass manufacturing

The formed sheet glass is then annealed in a controlled environment to relieve internal stresses. This step is crucial as it enhances the durability and strength of the glass. Annealing involves slowly cooling the glass to room temperature in a process known as an annealing lehr. This controlled cooling prevents the development of cracks and imperfections, ensuring that the glass meets the stringent quality standards required for various applications.

After the annealing process, the glass sheets are cut to the desired dimensions, polished, and inspected for quality. Various tests are conducted to ensure the glass meets safety standards and performance criteria, including impact resistance, optical clarity, and thermal stability. Once approved, the sheet glass is packaged carefully to prevent damage during transportation.

The advancements in technology have also led to the development of specialized sheet glass products, such as low-emissivity (Low-E) glass and laminated glass. Low-E glass is designed to reflect heat while allowing natural light to pass through, enhancing energy efficiency in buildings. Laminated glass consists of two or more layers of glass with an interlayer that provides additional safety and sound insulation.

In conclusion, sheet glass manufacturing is a complex yet fascinating process that combines raw materials, high temperatures, advanced techniques, and rigorous quality control. The result is a versatile product that finds applications in numerous sectors, significantly contributing to both functional and aesthetic aspects of modern design. As technology continues to evolve, the future of sheet glass manufacturing holds much promise for further innovation and sustainability.

Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu