Exploring the World of Silver Mirror Manufacturing

The silver mirror, a timeless and elegant reflective surface, has been a staple in homes, businesses, and various industries for centuries. The process of manufacturing silver mirrors involves meticulous attention to detail, advanced technology, and a deep understanding of materials. In this article, we will delve into the intricacies of silver mirror manufacturing, highlighting the key stages involved, technological advancements, and the environmental considerations that manufacturers must keep in mind.

The Manufacturing Process

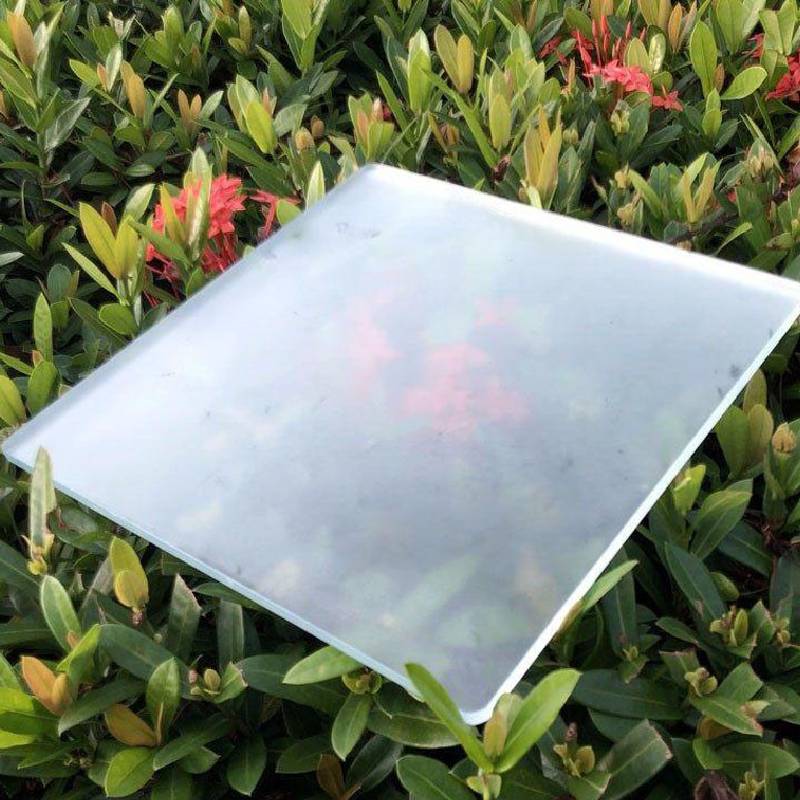

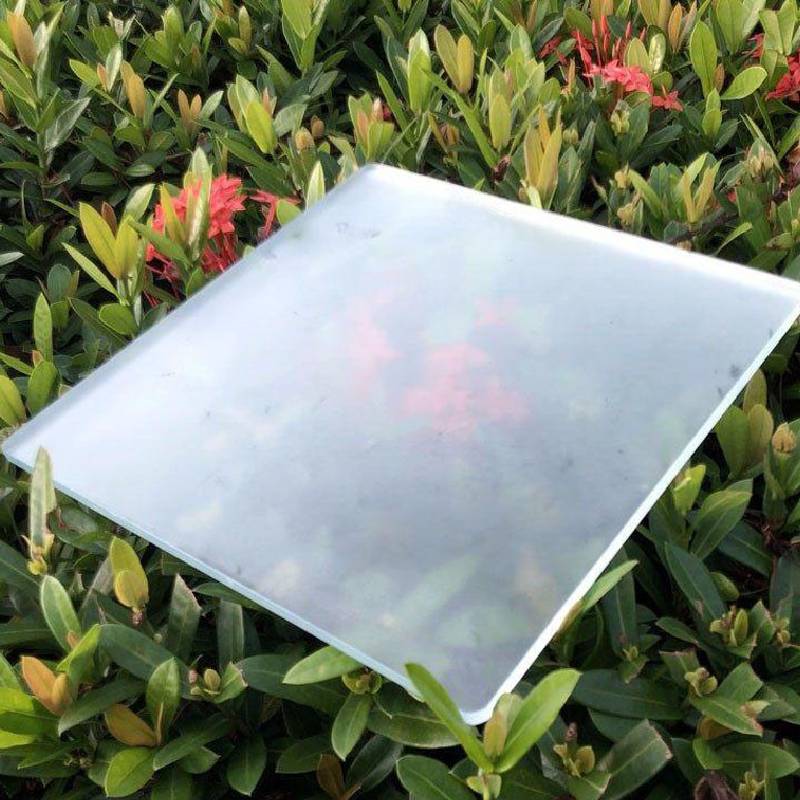

The journey of creating a silver mirror begins with the selection of high-quality glass. Floating glass, known for its smooth surface and clarity, is the primary choice. The first step in the manufacturing process is to cut the glass into the desired dimensions, followed by cleaning to remove any impurities that could affect the final finish.

After preparing the glass, the next step involves applying a thin layer of silver. This is typically done using a chemical process known as silvering. In this stage, a silver nitrate solution is applied to the glass surface. When exposed to reducing agents, the silver ions are converted into metallic silver, creating a reflective layer. This process requires precision, as uniformity in the silver layer is crucial for achieving a consistent and high-quality reflective surface.

After the silvering process, a protective coating is applied to prevent tarnishing and scratching. The coating, often composed of paint or lacquers, is essential to prolong the mirror's lifespan and maintain its aesthetic appeal. Finally, the mirrored glass undergoes additional quality checks to ensure there are no defects before being packaged and shipped to customers.

Technological Advancements

In recent years, the silver mirror manufacturing industry has embraced technology to enhance production efficiency and product quality. Automation has played a significant role in streamlining processes such as cutting, cleaning, and coating. Technological advancements have also introduced sophisticated quality control systems, including optical inspection tools that can detect flaws in the reflective surface or coating application.

Moreover, advancements in eco-friendly materials and processes are becoming increasingly important. Many manufacturers are exploring sustainable alternatives to traditional silvering methods, including the use of water-based coatings and reducing agents that minimize environmental impact. These innovations not only cater to the growing consumer demand for environmentally responsible products but also help companies reduce their carbon footprint.

silver mirror manufacturer

Market Trends and Consumer Preferences

The demand for silver mirrors spans various sectors, including residential, commercial, and automotive industries. In residential applications, consumers are increasingly favoring customized and decorative mirrors that enhance the space's aesthetic appeal. Interior design trends also dictate the shape, size, and finish of mirrors, driving manufacturers to adapt their offerings accordingly.

Online retailing has transformed the way consumers shop for mirrors. With the convenience of browsing and purchasing from home, manufacturers are leveraging e-commerce platforms to reach a wider audience. Social media also plays a vital role in influencing consumer preferences, with platforms like Instagram and Pinterest showcasing innovative mirror designs and home decor ideas.

Environmental Considerations

As consumer awareness of environmental issues continues to grow, silver mirror manufacturers are under pressure to adopt sustainable practices. This includes sourcing raw materials responsibly, optimizing energy consumption during production, and minimizing waste. Many companies are implementing recycling programs for used mirrors and packaging materials.

Additionally, certifications and eco-labels are becoming essential marketing tools that signal a manufacturer’s commitment to sustainability. By prioritizing eco-friendly practices, manufacturers can attract environmentally conscious consumers while ensuring compliance with regulations and standards.

Conclusion

The silver mirror manufacturing industry is a fascinating blend of tradition and innovation. As manufacturers refine their processes and adapt to changing consumer demands, they are not only enhancing the quality and aesthetic appeal of silver mirrors but also prioritizing sustainability. With continuous advancements in technology and an increasing focus on environmentally responsible practices, the future of silver mirror manufacturing looks promising and poised for growth. Whether in a modern home or a luxurious hotel lobby, silver mirrors continue to reflect beauty, elegance, and functionality.

Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu