1. What is the main difference between rain glass and frosted glass?

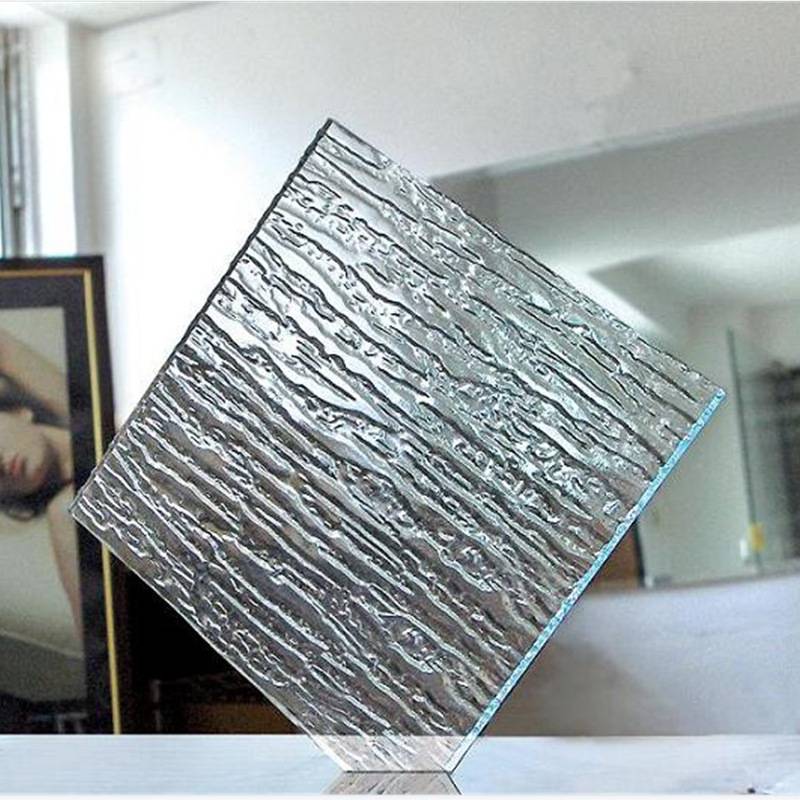

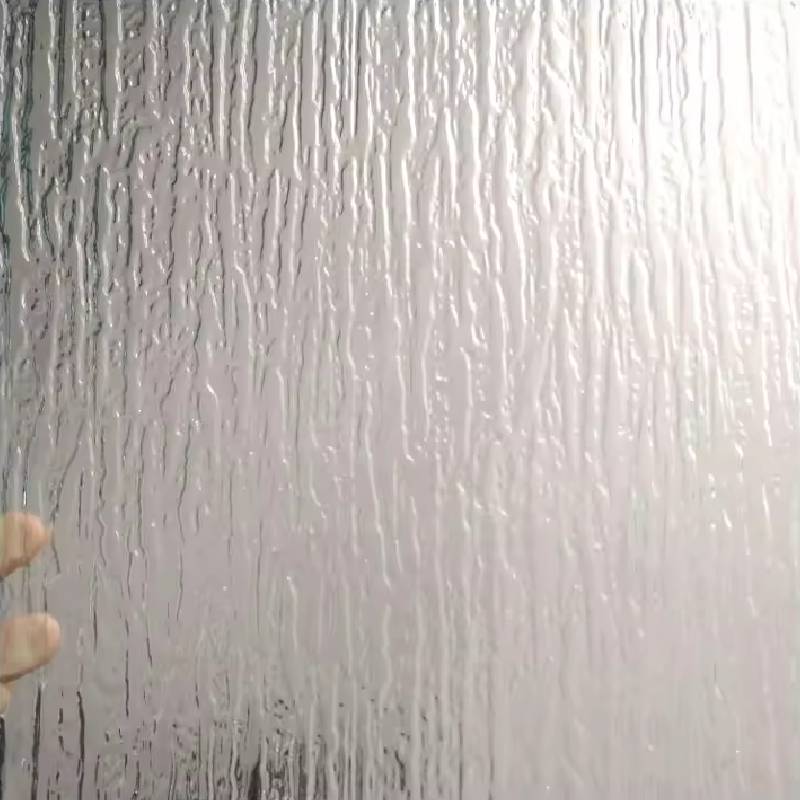

Rain glass's patterned surface is achieved by rolling molten glass between textured rollers, creating visual vertical ‘rain’ lines. Frosted glass is formed via sandblasting or acid-etching, producing a uniform, matte look but less light diffusion. Rain glass preserves more natural daylight and provides a dynamic privacy effect.

2. Are rain pattern glass and rainfall glass the same?

Yes, both refer to glass featuring a similar vertical, water-droplet-like texture, but "rainfall glass" sometimes implies larger droplet impressions. Check with your supplier for pattern samples.

3. What is the recommended installation standard for rain tempered glass?

Install per ANSI Z97.1/EN 12150-1 (for safety glazing): secure into frames with appropriate clearances (typically 3mm min) and use compatible silicone or EPDM gaskets to allow thermal expansion and absorb stress.

4. What is the minimum order size for custom rain pattern glass?

MOQ is usually 50m² for custom thickness/pattern design, but

standard rain glass is available from 5 pieces up.

5. What safety tests are performed on rain tempered glass?

Tests per ISO/ANSI: impact resistance (steel ball drop), fragmentation, light transmittance (ASTM E903), and thermal shock performance (EN 12150-1 Appendix A), all with full traceable records provided to clients.

6. Can rain glass be double glazed for better insulation?

Yes, rain glass can be combined in IGU (insulated glass units) for improved U-value and noise reduction, ideal for energy-efficient windows and doors.

7. What is the expected service life of rain glass in industrial environments?

Properly installed and maintained, 4mm–6mm rain glass routinely lasts 20–35 years, retaining at least 85% of initial clarity and pattern definition (laboratory test: EN 1096 accelerated weathering).

Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu