Understanding Standard Float Glass An Essential Material in Modern Construction

Standard float glass is a fundamental material widely utilized in various architectural and industrial applications. Known for its clarity, strength, and versatility, float glass has become a staple in windows, doors, and numerous other installations. This article explores the properties, manufacturing process, and applications of standard float glass, highlighting its significance in contemporary materials science and construction.

What is Float Glass?

Float glass is a flat glass product manufactured through the float process, which involves melting silica sand, soda ash, and limestone at high temperatures to form molten glass. This molten glass is then floated on a bath of molten tin, resulting in a smooth and uniform thickness. The floating method allows for the creation of large, flawless sheets of glass, free from imperfections that often plague other glass types. Once cooled, the glass is cut into sheets of various dimensions, which can then be further processed for specific applications.

Properties of Standard Float Glass

One of the defining characteristics of standard float glass is its optical clarity. It has a high light transmission rate, making it an ideal choice for applications requiring transparency, such as windows and display cases. Additionally, float glass has excellent durability, offering resistance to weathering, scratches, and chemical exposure. Its smooth surface makes it easy to clean and maintain, contributing to its long-lasting performance.

In terms of thermal properties, float glass has a moderate level of thermal conductivity and resistance, making it suitable for both indoor and outdoor settings. However, it is important to note that standard float glass is not inherently energy-efficient. The development of low-emissivity (low-E) coatings has enhanced its energy performance, allowing for better insulation and reduced energy costs in modern buildings.

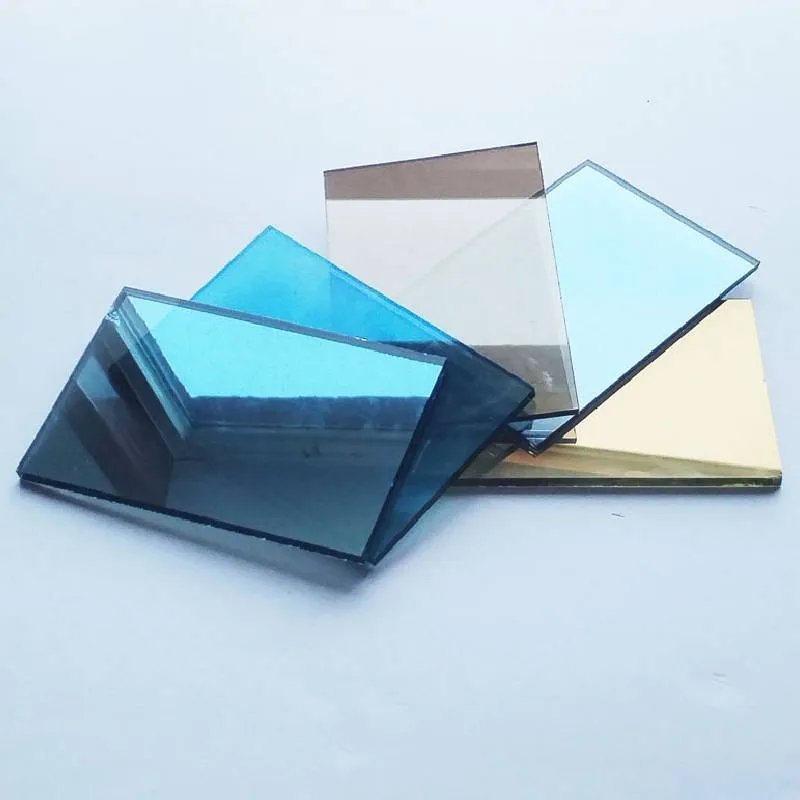

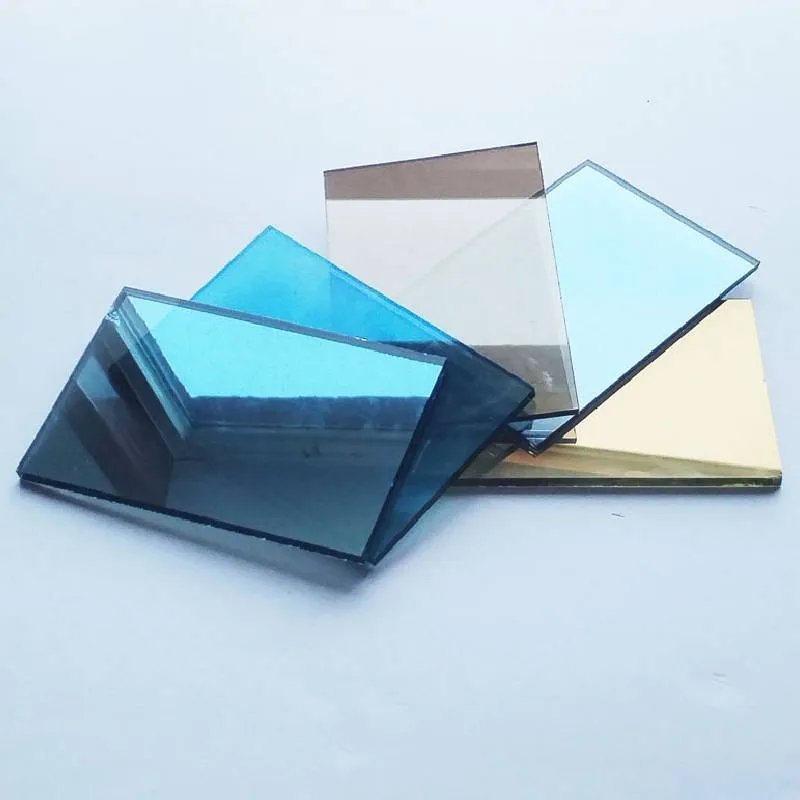

standard float glass

Applications of Standard Float Glass

The versatility of standard float glass extends to various sectors, including residential, commercial, and industrial applications. In the architectural realm, it is commonly used in facades, curtain walls, skylights, and partitioning. Its aesthetic appeal and ability to create bright, open spaces make it a favorite choice among architects and designers.

In addition to construction, float glass finds applications in automotive manufacturing, where it is used for windows and windshields that require high clarity and strength. The optical properties of float glass are also harnessed in the production of mirrors and glass furniture, contributing to the modern design aesthetic.

Furthermore, float glass is increasingly being integrated into smart technologies as innovations in glazing surfaces arise. This includes solar control glass that regulates heat gain and loss, as well as glass that can be transformed into interactive displays, showcasing the ongoing evolution of this timeless material.

Conclusion

In summary, standard float glass stands as a quintessential element in the world of construction and design. Its unique combination of clarity, durability, and versatility ensures its continued relevance in modern applications. As technology advances and the demand for innovative building materials increases, float glass will undoubtedly play a pivotal role in shaping the future of architecture and beyond.

Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu