Understanding Tempered Glass Key Features and Applications

Tempered glass, also known as toughened glass, is a type of safety glass that has been treated through controlled thermal or chemical processes to increase its strength compared to normal glass. Its enhanced properties make it a popular choice in various applications, ranging from architectural design to automotive manufacturing.

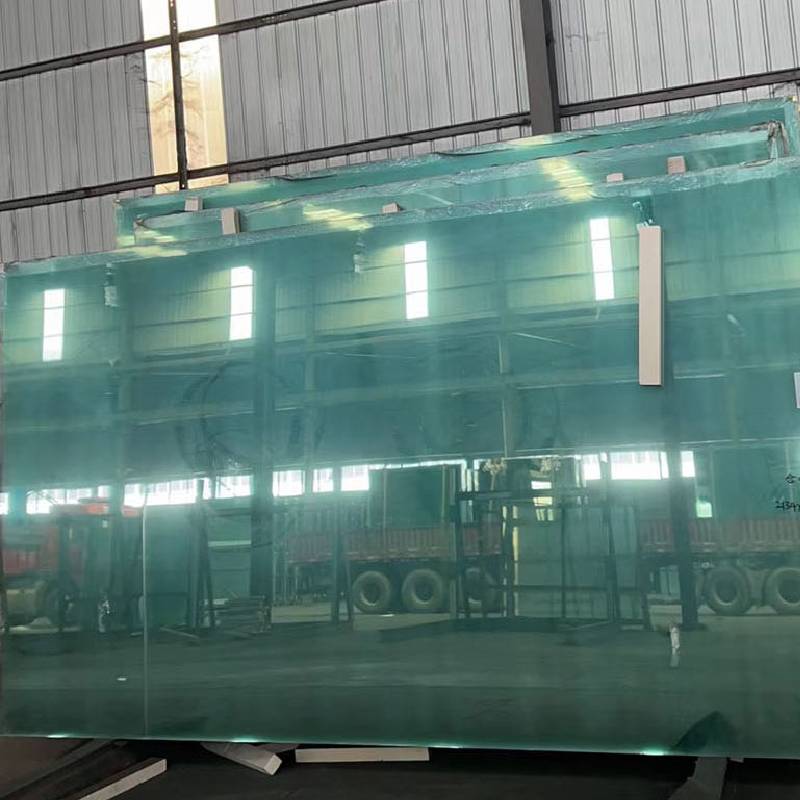

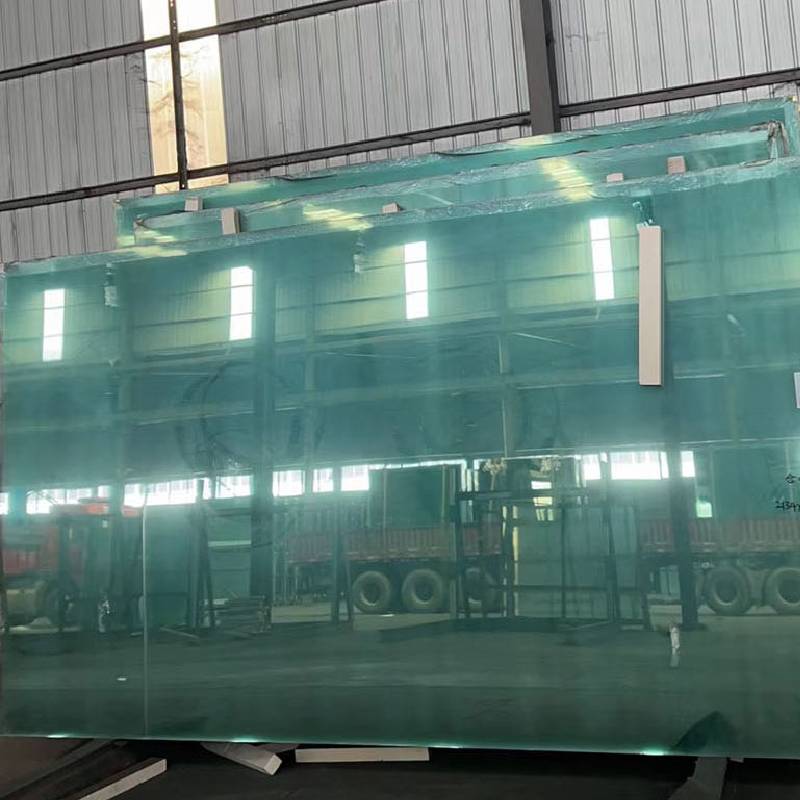

Production Process

The production of tempered glass involves heating the glass to over 600 degrees Celsius and then rapidly cooling it. This process, known as quenching, introduces compressive stresses on the surface of the glass, which significantly improves its strength. The resulting product is up to five times stronger than standard glass of the same thickness. Furthermore, if tempered glass does break, it shatters into small, blunt pieces rather than sharp shards, reducing the risk of injuries.

Physical and Thermal Properties

Tempered glass boasts several important physical properties. It has a high resistance to impact and thermal stress, making it suitable for environments that experience rapid temperature changes. For instance, it is often used in shower doors, glass facades, and glass tabletops where temperature fluctuations are common. The glass can withstand temperatures of up to 250 degrees Celsius, making it ideal for various industrial applications as well.

Additionally, tempered glass has excellent optical clarity, which makes it a favored choice for windows and skylights in commercial and residential buildings

. It provides clear visibility while offering added security and durability.

tempered glass data sheet

Applications

The versatility of tempered glass covers many industries. In architecture, it is used in facades, windows, and balustrades due to its strength and aesthetic appeal. Its ability to be fabricated into various shapes and sizes allows architects to push the boundaries of design while ensuring safety.

In the automotive industry, tempered glass is commonly utilized for side and rear windows. Its safety features are crucial, as it ensures driver and passenger protection in the event of an accident. Moreover, tempered glass can be found in appliances like ovens and stoves, where it can handle high heat and is easy to clean.

Regulatory Standards

Tempered glass must meet specific safety standards and regulations to be used in construction and other applications. Manufacturers often adhere to ASTM standards and other local regulations to ensure product quality and safety. These standards dictate the performance criteria for impact resistance, thermal stress, and overall durability.

Conclusion

In conclusion, tempered glass is an essential material that combines safety, durability, and aesthetic appeal. Its production process enhances its strength, allowing it to perform well in various challenging environments. From commercial buildings to automotive applications, tempered glass is a testament to engineering innovation that prioritizes safety without compromising on design. As demand for safe and durable materials continues to rise, tempered glass will undoubtedly remain a top choice across multiple industries.

Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu