The Art and Science of Tempered Glass Production

Tempered glass, also known as toughened glass, is a crucial material in modern construction, automotive design, and various applications requiring high durability and safety. Its production is a fascinating blend of art and science, transforming ordinary glass into a marvel of engineering that resists thermal stress and impact.

The journey of tempered glass begins with raw materials. The primary ingredient is silica sand, which is combined with soda ash and limestone to create glass. Other additives can include various metal oxides that enhance the glass’s strength and color. Once these materials are mixed and melted in a furnace at temperatures exceeding 1,700 degrees Fahrenheit (about 927 degrees Celsius), the resultant molten glass is then formed into sheets through various methods, depending on the desired final product.

The Art and Science of Tempered Glass Production

Tempering is a controlled heating and cooling process that significantly increases the strength of the glass. The glass sheets are heated to approximately 1,200 degrees Fahrenheit (about 650 degrees Celsius) and held at that temperature for a set duration. This heating phase ensures even temperature distribution, allowing the material to undergo a structural transformation.

tempered glass maker

Once the heating phase is complete, the glass sheets are rapidly cooled by a process known as quenching. High-volume air jets blow cool air onto the surface of the heated glass, leading to a rapid temperature drop. This sudden cooling causes the outer surfaces of the glass to contract faster than the inner layers, creating a state of compressive stress on the outside. This unique balancing of internal stresses makes tempered glass about four to five times stronger than standard (annealed) glass of the same thickness.

In addition to its strength, tempered glass has notable safety advantages. When broken, it shatters into small, blunt pieces rather than sharp shards, minimizing the risk of injury. This characteristic makes tempered glass the preferred choice for high-traffic areas, building facades, shower doors, and even glass furniture.

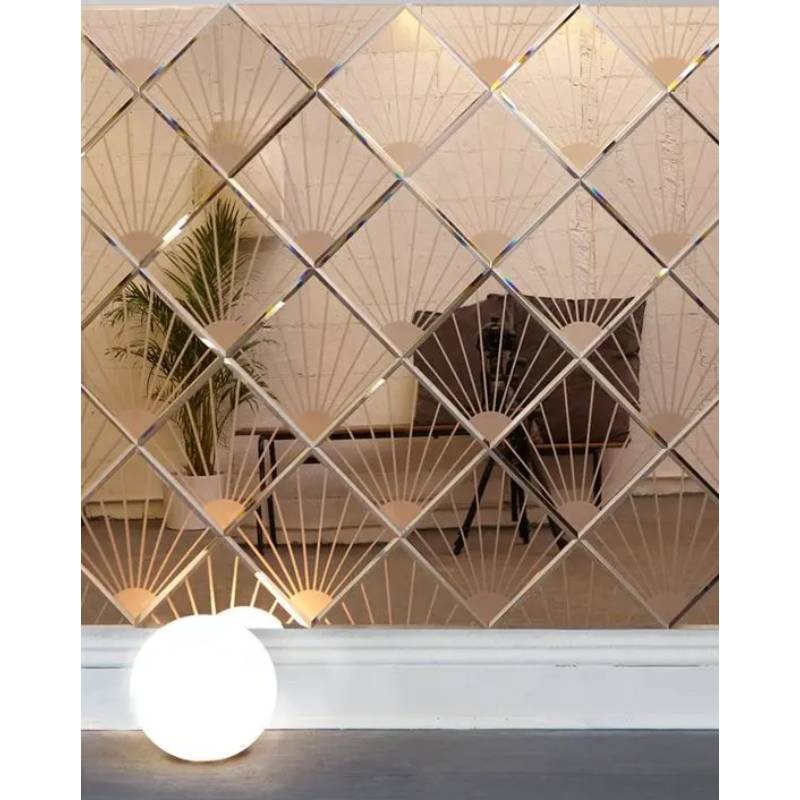

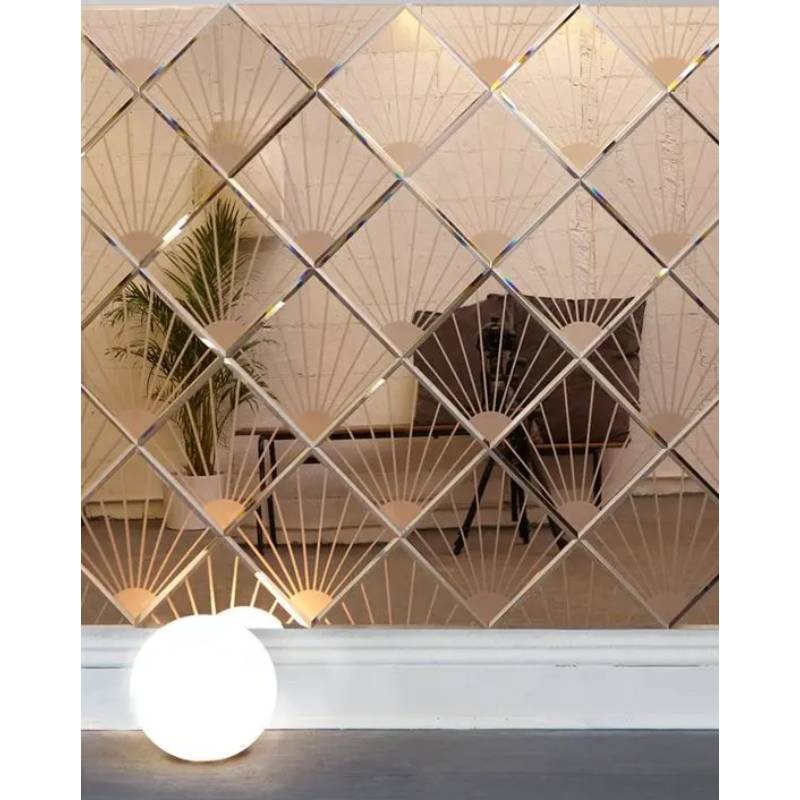

The versatility of tempered glass extends beyond physical properties. It can be manufactured in a variety of colors and finishes, including frosted, tinted, or reflective options, allowing architects and designers to play creatively with light and aesthetics. Furthermore, tempered glass can be laminated or coated for added functionalities, such as UV protection or sound insulation.

With the increasing demand for sustainable building materials, tempered glass has also gained attention for its energy efficiency. It plays a significant role in modern energy-efficient designs, helping to reduce heat loss and improve insulation in buildings. When used in double or triple glazing systems, tempered glass enhances thermal performance, contributing to lower energy consumption in residential and commercial buildings.

In conclusion, the production of tempered glass is a complex yet fascinating process that marries art with science, resulting in a safe, strong, and versatile material that continues to shape our environments. From its raw materials to its transformative tempering process, tempered glass exemplifies innovation in material science. As we look toward the future, its applications are only set to expand, underscoring its vital role in sustainable design and safety in our daily lives. Ensuring high standards in production and quality control, tempered glass makers are crucial to delivering these exceptional products that blend functionality with artistry.

Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu