Tempered Glass Maker The Art and Science of Resilience

In the modern world, tempered glass has become a quintessential material widely used in various applications, from architecture and automotive to electronics and furniture. Known for its exceptional strength and safety properties, tempered glass undergoes a meticulous process of heating and cooling, which makes it up to five times stronger than standard glass. The role of a tempered glass maker is thus not only vital but also fascinating, blending artistry with science and engineering.

The journey of tempered glass begins with the selection of high-quality raw materials. A tempered glass maker sources silica sand, soda ash, and limestone, which are essential components of glass production. The quality of these materials directly influences the final product’s clarity and durability. Once the materials are procured, they undergo a precise blending process, ensuring a uniform mixture free of impurities. This initial step is crucial, as even minute contaminants can compromise the glass’s integrity.

The next phase involves melting the mixture in a furnace at extremely high temperatures, usually around 1,650 degrees Fahrenheit (900 degrees Celsius). During this stage, the raw materials transform into a molten liquid, which must be handled with the utmost care. The skill of a tempered glass maker shines here, as timing and temperature control are critical. Any deviation can lead to defects, causing the glass to weaken or shatter unexpectedly.

Once the glass is molten, it is carefully shaped into sheets or specific forms using various techniques, such as floating, pressing, or blowing. The process of forming demands not only precision but also creativity, as designers and makers collaborate to bring innovative ideas to life. The resulting sheets of glass can vary in thickness, size, and texture, allowing for diverse applications in buildings, vehicles, and decorative elements.

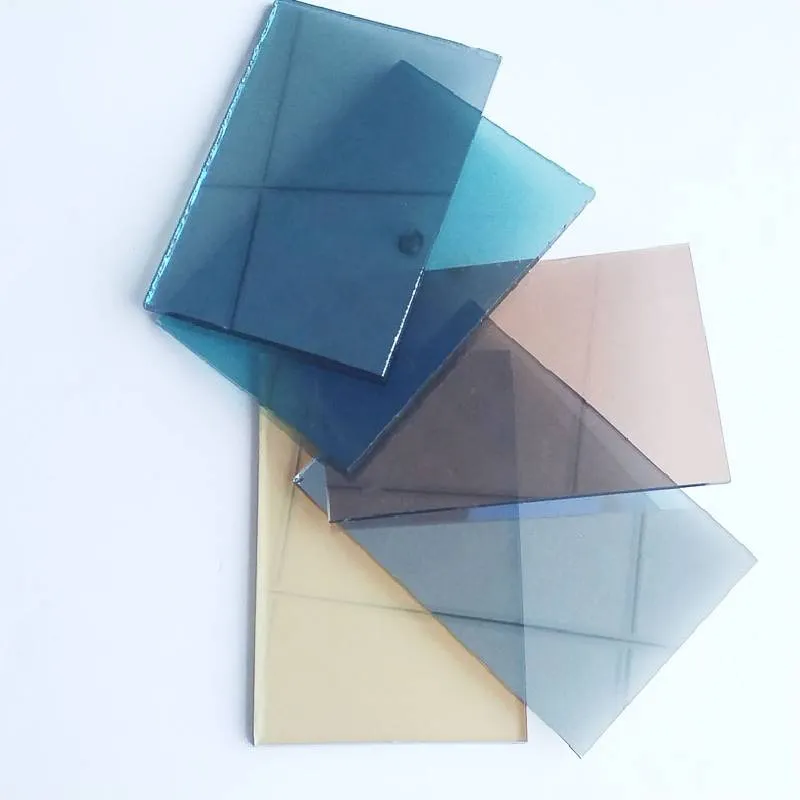

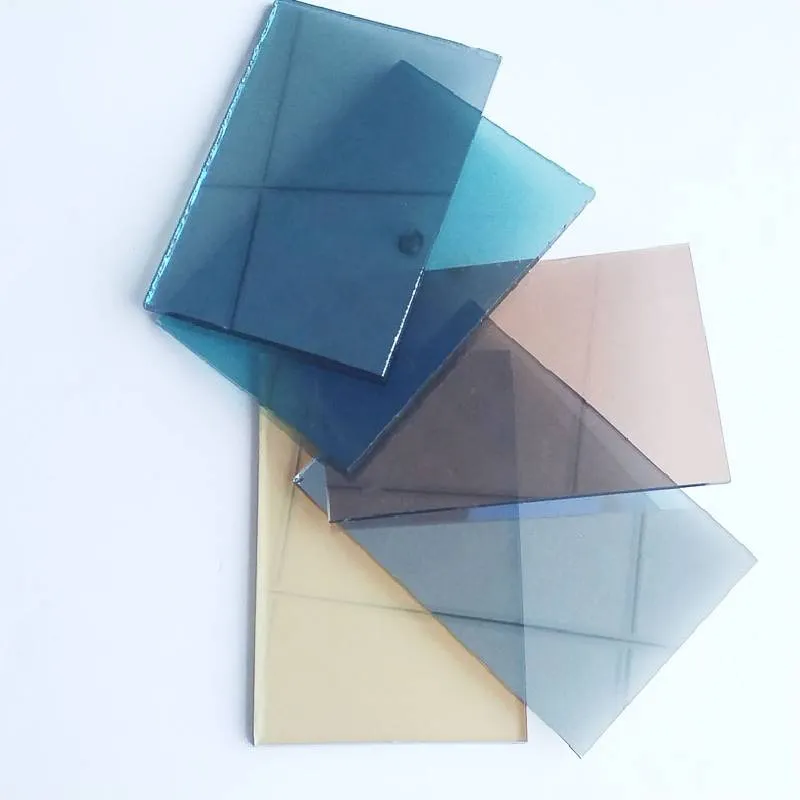

tempered glass maker

After the shaping process, the real magic begins with tempering, a phase that sets tempered glass apart from untreated varieties. The glass sheets are subjected to rapid heating, followed by an equally swift cooling process, known as quenching. This thermal treatment increases the glass's strength by inducing compressive stresses on its surface. The cooling rate and temperature are meticulously monitored to achieve the desired properties. A skilled tempered glass maker understands the delicate balance of these variables, ensuring that each piece meets stringent safety standards.

One of the most significant advantages of tempered glass is its safety feature. In the event of breakage, tempered glass shatters into small, blunt pieces rather than sharp shards, reducing the risk of injury. This characteristic makes it an ideal choice for various safety-critical applications, such as in cars, shower doors, and glass facades. The tempering process empowers architects and designers to create expansive glass structures that are not only aesthetically pleasing but also secure.

Moreover, tempered glass makers are increasingly adopting advanced technologies to enhance their production capabilities. Automated cutting machines, robotic handling systems, and computer-controlled tempering ovens streamline the manufacturing process, ensuring consistency and efficiency. However, even with automation, the human element remains indispensable. The expertise of seasoned craftsmen is still pivotal in monitoring the process, diagnosing potential issues, and making necessary adjustments.

Sustainability is another focal point for modern tempered glass makers. With a rising global emphasis on environmental responsibility, manufacturers are exploring eco-friendly practices, such as recycling glass and utilizing energy-efficient production techniques. This shift towards sustainability not only benefits the planet but also enhances the appeal of tempered glass, which is often seen as a green building material.

In conclusion, the role of a tempered glass maker is a blend of artistry, precision, and innovation. From sourcing raw materials to executing complex manufacturing processes, these professionals create a material that is essential to contemporary life. As technology advances and sustainability becomes a priority, tempered glass makers continue to adapt and innovate, ensuring that their craft remains relevant in an ever-changing world. The result is a resilient product that not only meets safety and aesthetic demands but also contributes to a more sustainable future.

Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu