Tempered glass, also known as toughened glass, is a type of safety glass that is manufactured through a process of extreme heating and rapid cooling. This process enhances the strength and thermal resistance of the glass, making it ideal for various applications, including in buildings, automobiles, and electronic devices.

The tempered glass process begins with selecting a suitable type of glass, typically float glass, which is known for its uniform thickness and clarity. Once the glass is chosen, it is cut to the desired size and shape. Precision is critical at this stage, as any imperfections can compromise the entire production process.

After cutting, the glass undergoes a cleaning process to remove any dust, dirt, or grease. This step is crucial because contaminants can lead to defects during the tempering process. Once the glass is cleaned, it is ready for heating. The glass is placed in a furnace where temperatures can reach up to 620 degrees Celsius (about 1,150 degrees Fahrenheit). This heating phase allows the glass to reach its softening point, making it pliable.

After reaching the appropriate temperature, the glass is removed from the furnace and subjected to rapid cooling, or quenching. This is achieved by blowing cool air onto the glass surface. The rapid drop in temperature creates a balance of internal stresses; the outer surface cools and solidifies faster than the inner part, resulting in a hardened structure. This thermal treatment increases the overall strength of the glass, allowing it to withstand impacts and high thermal variations that ordinary glass cannot endure.

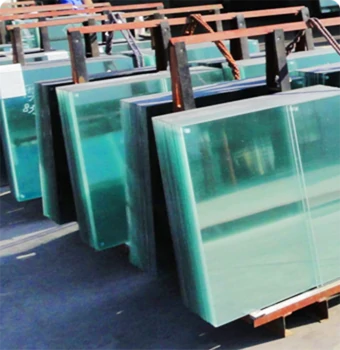

tempered glass process

The quality of tempered glass is evaluated through rigorous testing methods, ensuring it meets safety standards. When broken, tempered glass shatters into small, blunt pieces rather than sharp shards, minimizing the risk of injury—an essential characteristic for safety applications.

The applications of tempered glass are vast and varied. It is commonly used in residential and commercial buildings for windows, doors, and facades due to its strength and aesthetic appeal. In the automotive industry, tempered glass is used for windshields and side windows. Additionally, it is employed in electronic devices, shower doors, and glass partitions, making it a versatile component in modern architecture and design.

In conclusion, the tempered glass process is a sophisticated manufacturing method that transforms ordinary glass into a strong, safe material suitable for numerous applications. Its ability to resist thermal stress and minimize injury upon breakage underscores its importance in modern construction and design.

Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu