Understanding Tempered Glass Quality A Key to Safety and Durability

Tempered glass, also known as toughened glass, plays a crucial role in various applications, from architecture to automotive industries. Its enhanced strength and safety features make it a preferred choice for homeowners, businesses, and manufacturers. This article delves into the quality of tempered glass, outlining its production processes, benefits, and factors that contribute to its overall integrity.

Production Process of Tempered Glass

The quality of tempered glass begins with its manufacturing process. Tempered glass is created through a process of extreme heating and rapid cooling. First, the glass is cut to the desired size and shape before being heated in an oven to about 620-650 degrees Celsius. This high temperature alters the structure of the glass, making it more durable. After maintaining this temperature for a specified time, the glass is rapidly cooled using air jets. This cooling process is pivotal; it introduces compressive stress on the surface of the glass and tensile stress within, which significantly enhances its strength compared to standard glass.

An essential aspect of ensuring quality tempered glass is adhering to international standards and regulations. Various organizations, such as the American National Standards Institute (ANSI) and the Glass Association of North America (GANA), establish guidelines that manufacturers must follow. Compliance with these standards assures consumers that the tempered glass has undergone rigorous testing and meets safety requirements.

Benefits of Tempered Glass

The quality of tempered glass manifests in numerous benefits. One of the most significant advantages is its impact resistance. Tempered glass is approximately five to six times stronger than regular glass of the same thickness. This durability makes it an excellent choice for buildings, showers, and vehicle windows, where the risk of breakage is pronounced. In the event of a break, tempered glass shatters into small, blunt pieces rather than sharp shards, significantly reducing the risk of injury.

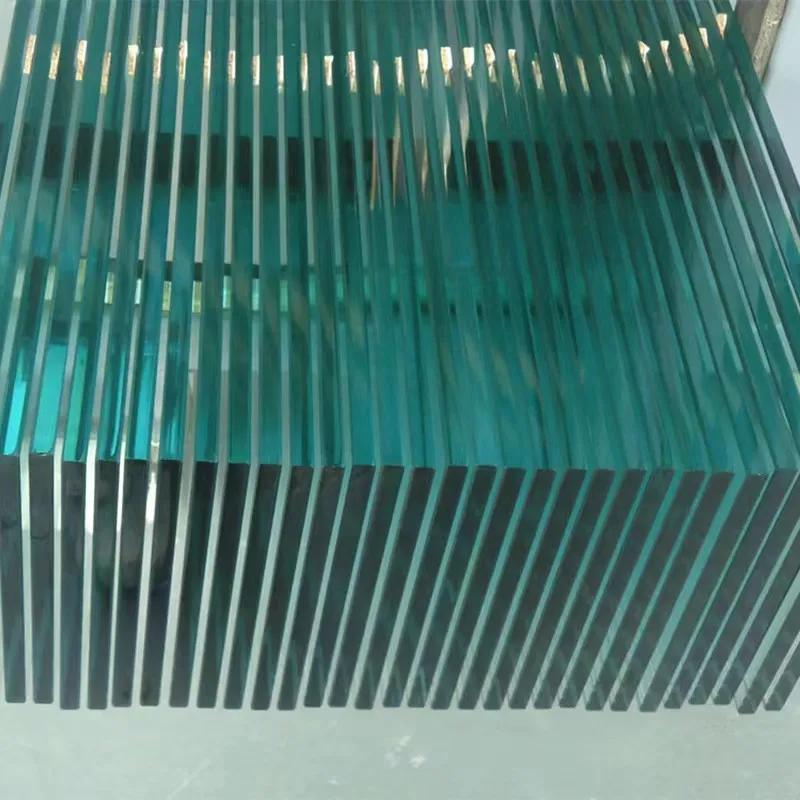

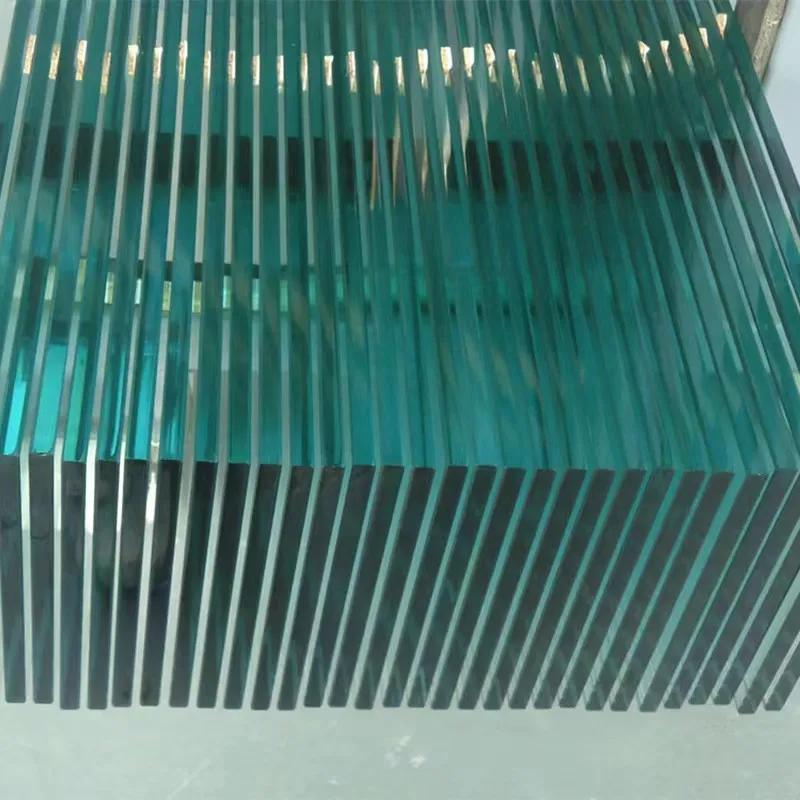

tempered glass quality

Additionally, tempered glass can withstand extreme temperature variations, making it suitable for applications such as oven doors or glass railings exposed to the elements. Its thermal resistance is another quality that enhances its usability in diverse environments. Furthermore, tempered glass offers aesthetic appeal; it comes in various thicknesses, finishes, and tints, allowing architects and designers to creatively integrate it into their projects without compromising on safety.

Factors Affecting Quality

While the production process determines the initial quality of tempered glass, several factors can influence its performance and longevity. The quality of the raw materials used in manufacturing is paramount. Low-quality raw materials can lead to inconsistencies and defects in the finished product, compromising safety and functionality. Additionally, the precision in the heating and cooling process significantly affects the final strength of the glass. Manufacturers must carefully control the temperature and time to ensure that the glass reaches the necessary thermal threshold.

Another critical factor is the installation process. Even the highest quality tempered glass can fail if not properly installed. It’s essential to use appropriate edging and fittings to avoid excessive stress concentration in certain areas. Furthermore, regular maintenance is vital to preserve the quality of tempered glass. Cleaning with suitable materials and avoiding harsh chemicals can prevent deterioration over time.

Conclusion

In conclusion, the quality of tempered glass is integral to its effectiveness and safety across various applications. Understanding its production process, benefits, and the factors that influence its integrity allows consumers and professionals to make informed decisions. As technology advances and new standards emerge, the glass industry will continue to evolve, ensuring that tempered glass remains at the forefront of safety and durability. Whether used in residential, commercial, or industrial settings, the superior qualities of tempered glass make it a material of choice for builders and designers committed to quality and safety.

Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu