Thermal Tempering of Glass Enhancing Strength and Safety

Thermal tempering of glass is a crucial process in the manufacturing of safety glass that enhances its strength and resilience. This method involves heating glass to high temperatures and then cooling it rapidly, resulting in a product that can withstand significant stress and impact. The process and its implications are vital for various applications, including automotive, architectural, and even artistic fields.

The Process of Thermal Tempering

The thermal tempering process begins with the selection of raw glass, which is then cut to the desired size and shape. The glass is placed in a furnace where it is heated to temperatures between 600°C and 620°C (about 1,112°F to 1,148°F). This heating phase is crucial because it allows the internal stresses within the glass to relax. Following this, the glass is subjected to a rapid cooling phase called quenching. Air jets are used to cool the surface of the glass quickly, while the interior remains hot for a little longer. This temperature difference creates compressive stresses on the surface of the glass and tensile stresses in the interior.

The result is a glass that is four to five times stronger than standard, untreated glass. This increased strength makes thermal tempered glass ideal for environments where safety is paramount, such as in car windows, shower doors, and facades of commercial buildings.

Advantages of Thermal Tempering

One of the primary advantages of thermal tempering is its ability to enhance the safety of glass products. In the event of breakage, tempered glass fractures into small, blunt pieces rather than sharp shards, reducing the risk of injury. This property is particularly important in high-traffic areas where glass installations are prone to accidental impact.

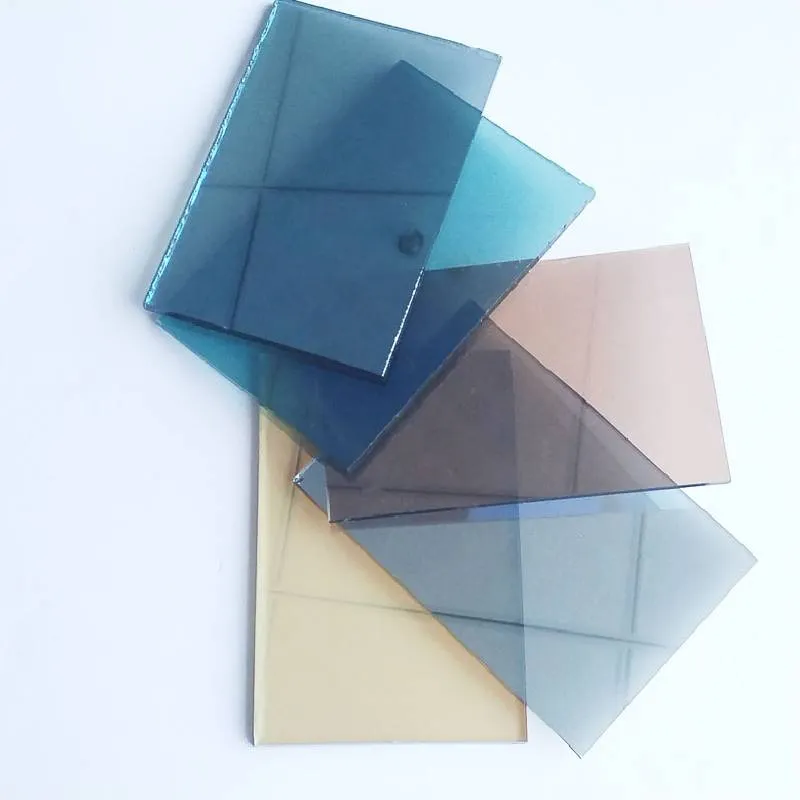

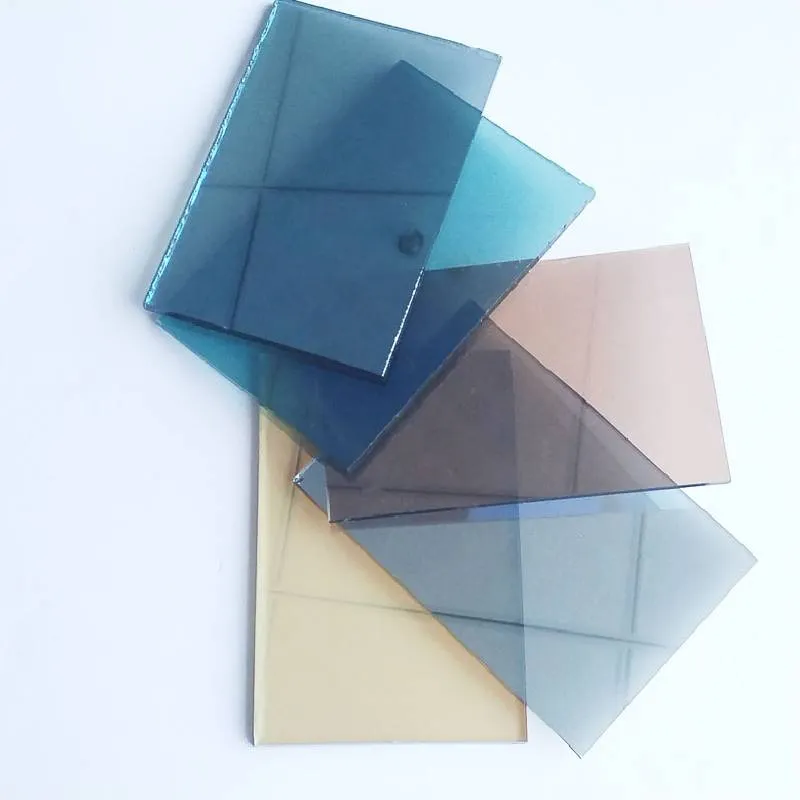

thermal tempering of glass

Another advantage is the thermal stability that tempered glass provides. It can withstand higher temperature fluctuations than standard glass, making it suitable for applications such as glass doors in kitchens or buildings exposed to direct sunlight. The enhanced thermal resistance not only improves durability but also ensures that the glass maintains its structural integrity under varying weather conditions.

Moreover, the aesthetic appeal of thermal tempered glass cannot be overlooked. It can be manufactured with various surface finishes, colors, and patterns, allowing architects and designers more freedom to innovate. The versatility of tempered glass opens up endless possibilities for creative and functional designs, from modern skyscrapers to elegant interior features.

Applications of Thermal Tempered Glass

The applications for thermal tempered glass are vast and varied. In the automotive industry, it is used for side windows, sunroofs, and windshields. The automotive sector demands high durability and safety, and thermal tempered glass meets these requirements effectively. In architecture, many contemporary buildings utilize tempered glass in their façades and skylights due to its strength, safety, and aesthetic versatility.

Additionally, thermal tempered glass plays a crucial role in interior design, particularly in shower enclosures and glass partitions where both safety and style are essential. In the realm of furniture design, tempered glass is frequently used for tabletops and shelving, combining functionality with elegance.

Conclusion

In conclusion, thermal tempering of glass is a transformative process that significantly enhances the strength, safety, and versatility of glass products. From improving the safety of everyday items to expanding the creative potential of architects and designers, the benefits of this technology are far-reaching. As industries continue to evolve, the demand for safe and durable glass solutions will only increase, solidifying the central role of thermal tempering in glass manufacturing. This process not only ensures the practical applications of glass but also elevates its aesthetic value, marking a significant advancement in material technology.

Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu