Toughened glass, also known as tempered glass, is a type of safety glass processed by controlled thermal or chemical treatments to increase its strength compared to normal glass. It is used where strength, thermal resistance, and safety are a necessity. For projects needing glass that fits unique spaces or specifications, the option to have toughened glass cut to order offers extraordinary advantages in terms of safety and aesthetic appeal—merging expert craftsmanship with durable design.

When choosing toughened glass as the material for your project, you are investing in enhanced safety. Unlike ordinary glass that shatters into jagged shards when broken, toughened glass fractures into small, blunt pieces less likely to cause significant injury. This characteristic makes it indispensable for places with stringent safety standards, such as offices, homes with young children, and commercial spaces like restaurants and malls.

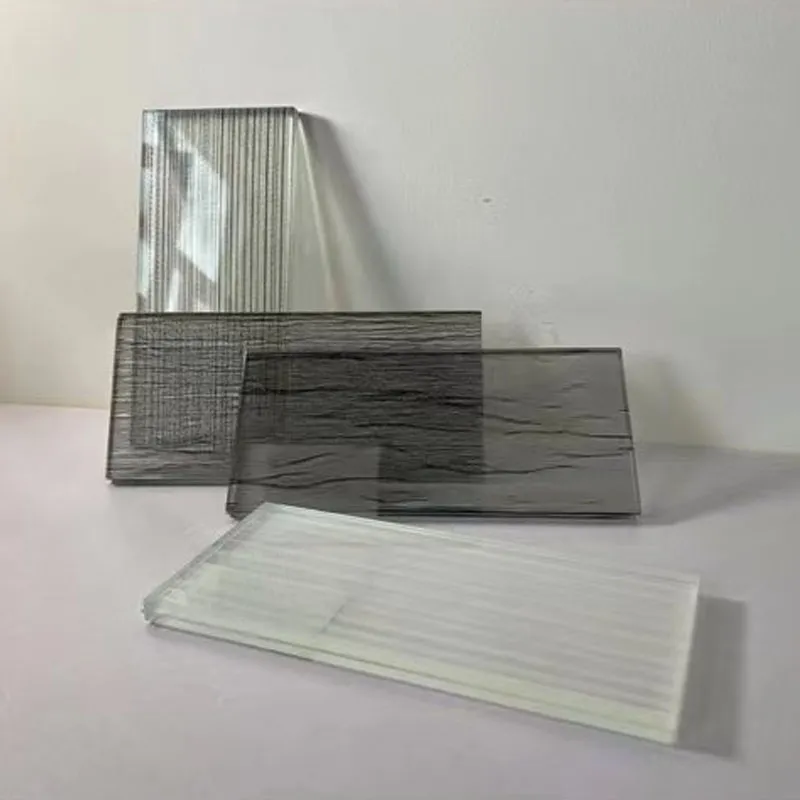

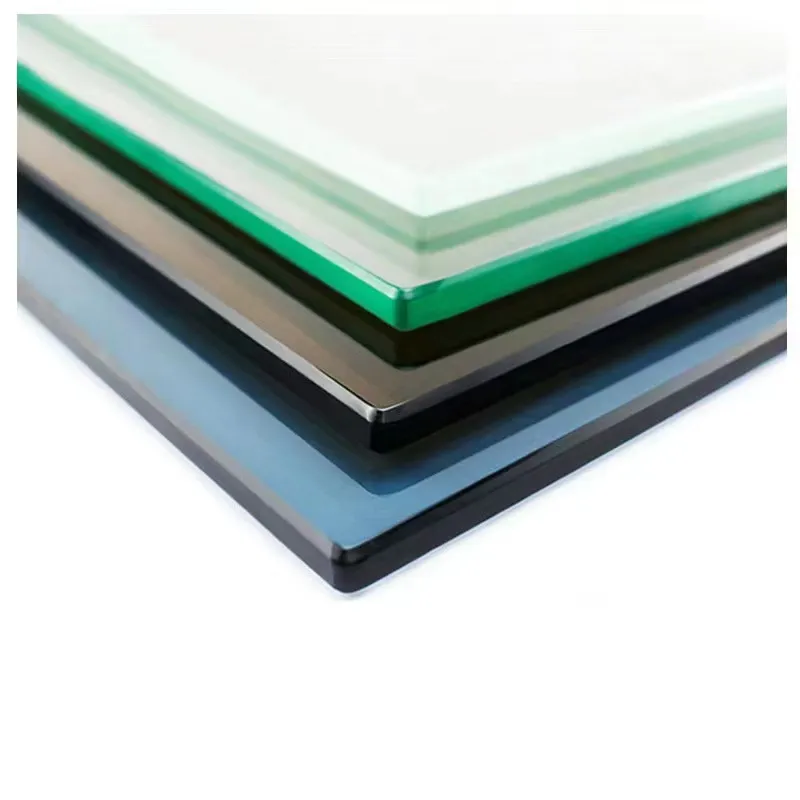

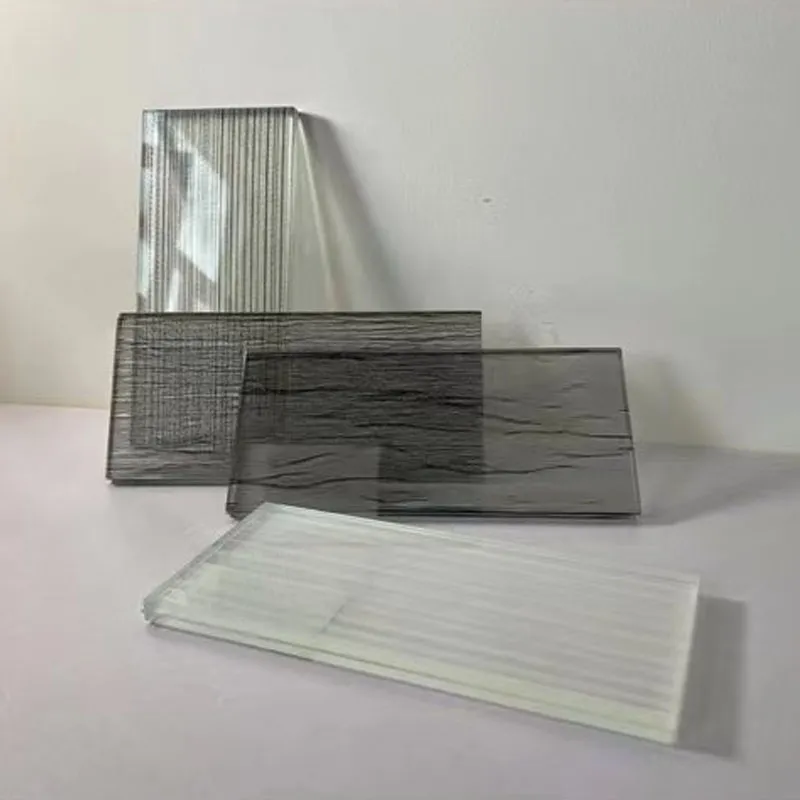

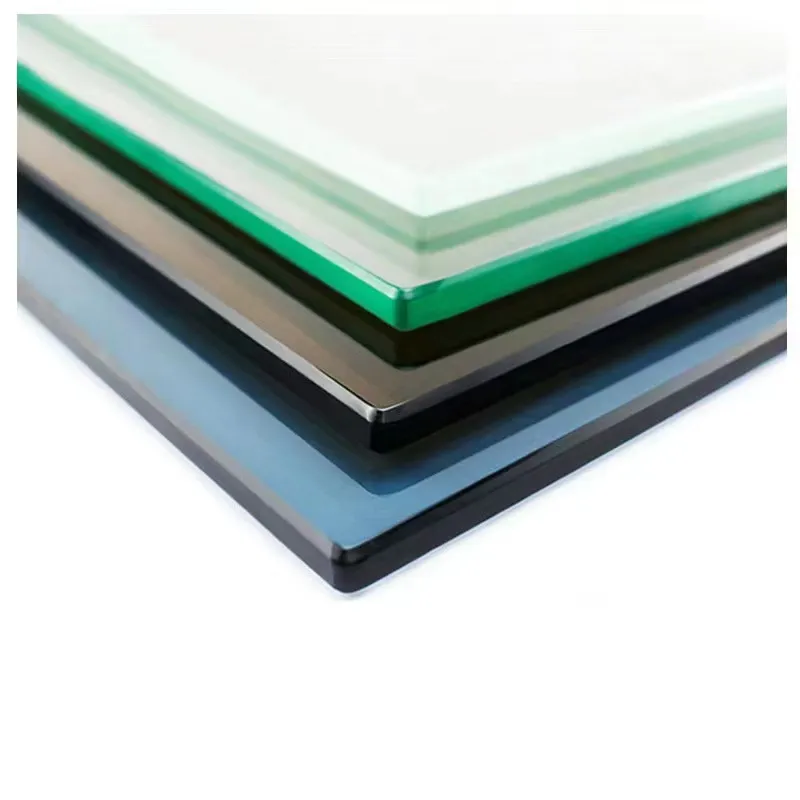

Customization is one of the primary advantages of ordering toughened glass tailored to specific measurements. Bespoke sizes meet the demands of modern architecture and interior design, allowing for seamless integration into any space. This is especially significant in contemporary home design, whether it's for sleek shower screens, expansive windows that capture panoramic views, kitchen splashbacks, or glass doors that open into garden areas. Architects and interior designers prefer toughened glass for these uses because its customizable nature enhances both form and function.

Craftsmanship in cutting and processing toughened glass is a specialized skill. Only professionals with extensive experience should undertake the task. The process involves precise cutting and shaping in predetermined dimensions before the glass undergoes tempering. Once tempered, the glass cannot be cut or drilled; this underscores the need for precision before the tempering process begins. Expert glass processors utilize state-of-the-art technology to ensure each pane fits exact specifications, and this meticulous attention to detail is an assurance of quality that affects the overall aesthetics and safety of the structure.

toughened glass cut to order

The authority and trustworthiness of suppliers in the toughened glass industry directly impact the quality of the material. Reputable suppliers are often affiliated with recognized industry bodies and adhere to international standards of safety and quality, such as EN12150-1 in Europe or ANSI Z97.1 and CPSC 16 CFR 1201 in the United States. Before choosing a supplier, checking these certifications is crucial. Esteemed suppliers provide not merely the glass itself but also guidance on installation and maintenance, ensuring their customers have a holistic understanding of how to handle and care for their glass structures.

User experience often tells the story of the product's true value. Testimonials and case studies from previous clients speak volumes. A platform showcasing innovative uses of toughened glass can inspire potential buyers, illustrating how a custom-cut glass project can transform spaces. For example, a minimalist residential kitchen might feature a dramatic toughened glass backsplash that combines functionality with striking visual appeal. Such galleries and client stories not only demonstrate the versatility of the product but also build trust and authority by showing that others have harnessed the product to positive effect.

In summary, toughened glass cut to order provides a blend of safety, aesthetic flexibility, and functional excellence. It accommodates personalized design specifications while ensuring compliance with the highest safety standards. By engaging skilled professionals and choosing certified suppliers, consumers are assured of a product that will enhance their environment in a safe, stylish, and enduring manner. This empowers projects with an unmatched balance of security and sophistication, keeping spaces not only beautiful but also secure.

Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu