The Art and Science of Toughened Glass Making

Toughened glass, also known as tempered glass, is a remarkable material that has revolutionized various industries, from construction to automotive. The manufacturing process of toughened glass involves a unique set of techniques that enhance its strength and safety features, making it a preferred choice for applications where durability is paramount. This article delves into the intricacies of toughened glass making, exploring its benefits, processes, and applications.

Understanding Toughened Glass

Toughened glass is produced through a special thermal treatment process that involves heating the glass to high temperatures, typically around 600 degrees Celsius, and then rapidly cooling it. This process alters the internal structure of the glass, distributing stress evenly throughout the material. As a result, toughened glass is significantly stronger than standard glass, able to withstand impact, thermal fluctuations, and even shattering when broken. When broken, it crumbles into small, blunt pieces, reducing the risk of injury.

The Toughening Process

The manufacturing of toughened glass starts with standard float glass, which is produced by floating molten glass on top of molten metal. The quality of this raw material is crucial, as any imperfections can affect the final product's durability. Once the float glass is cut to the desired size, it undergoes the toughening process, which includes several key stages

1. Heating The cut glass panels are placed in a tempering furnace where they are heated uniformly to the designated temperature. This ensures that all parts of the glass achieve the necessary strength characteristics.

2. Rapid Cooling After reaching the desired temperature, the glass panels are subjected to a process known as quenching. High-pressure air jets blow onto the glass, rapidly cooling its surface while the core remains at a higher temperature. This creates a state of compression on the surface of the glass, which is essential for its toughness.

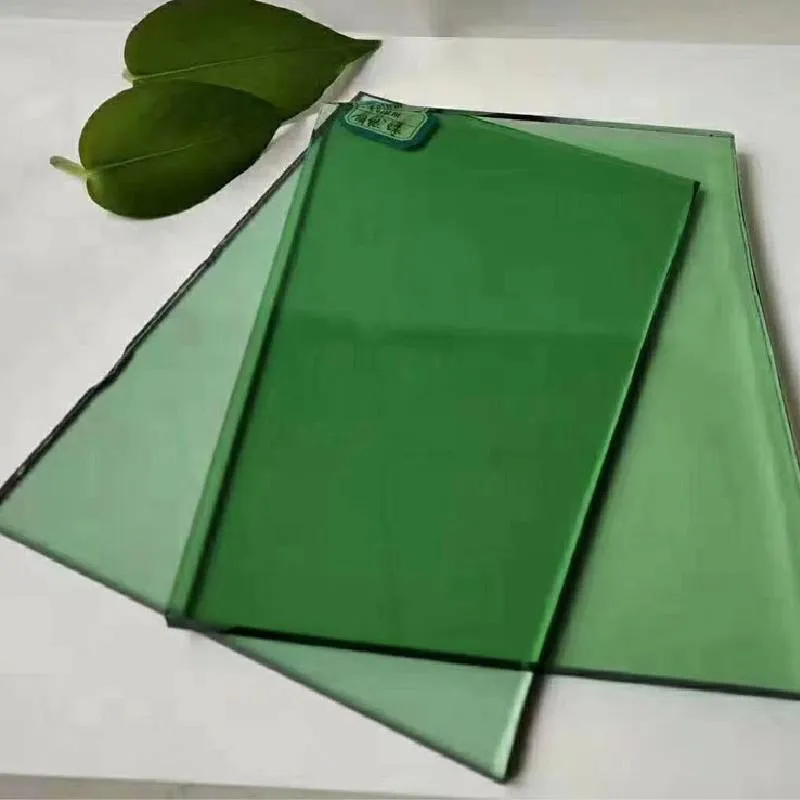

toughened glass making

3. Inspection Once the toughened glass has cooled, it undergoes rigorous quality control checks. Technicians inspect the glass for any defects, ensuring that it meets industry standards for safety and performance.

4. Cutting and Finishing After passing inspection, the toughened glass can be cut to specific dimensions or finished further depending on its intended use. This process may involve polishing the edges or applying coatings for additional properties, such as UV resistance.

The Advantages of Toughened Glass

The benefits of toughened glass are manifold. Its strength makes it an excellent choice for architectural applications, including facades, glass doors, and skylights. It is also used extensively in the automobile industry for windows and windshields, where safety and durability are paramount.

Additionally, toughened glass is energy-efficient, as it can be manufactured to hold insulation properties, contributing to better thermal management in buildings. Furthermore, its ability to resist breakage and shatter into harmless pieces makes it an ideal choice for environments where safety is a concern, such as schools and homes.

Conclusion

In conclusion, the making of toughened glass is a sophisticated combination of art and science. Through a carefully controlled heating and cooling process, manufacturers produce a material that is not only aesthetically pleasing but also exceptionally strong and safe. As industries continue to innovate and prioritize safety and sustainability, toughened glass will undoubtedly remain a pivotal component in the design and construction of modern structures, vehicles, and a myriad of other applications. Its transformative qualities will continue to contribute to a safer and more visually captivating world.

Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu