Toughened glass, also known as tempered glass, stands as an exemplary choice in industries where safety and durability hold paramount importance. This glass is manufactured through a process that not only enhances its strength but also guarantees a higher standard of safety compared to regular glass. The art of toughened glass making is steeped in both engineering precision and innovative technology, offering an unrivaled product that meets the stringent demands of modern design and architecture.

The primary appeal of toughened glass lies in its remarkable robustness. It is engineered to withstand impact and stress, often without shattering, which makes it an ideal candidate for use in construction, automotive, and interior design industries. The process begins with heating ordinary glass to a temperature of approximately 620 degrees Celsius. This is followed by a rapid cooling phase, where air is blasted onto the glass surfaces. This sudden cooling solidifies the outer surfaces of the glass while the core cools more slowly, creating balanced internal stress. This unique compositional tension bestows upon toughened glass its formidable strength, making it up to five times stronger than untreated glass.

Expertise in toughened glass manufacturing is not just about understanding the process but entails a thorough grasp of its applications. For instance, its high thermal resistance makes it a valuable addition in environments exposed to drastic temperature variations. This quality ensures that toughened glass does not warp or deform under intense heat, a trait highly valued in kitchen appliances and architectural glass façades, where thermal stability is crucial.

Professionalism in this domain also involves an appreciation for safety, the hallmark of toughened glass. Upon receiving a heavy impact, toughened glass crumbles into small, blunt-edged granules rather than jagged shards. This characteristic highlights its suitability for environments accessible to children and the general public, such as glass doors, shower screens, and public transport windows. The safety profile of toughened glass not only meets but often exceeds regulatory standards across different industries, making it a preferred choice for manufacturers and architects alike.

The authoritativeness of toughened glass as a material is well-documented in building codes and safety regulations worldwide. This endorsement stems from an extensive body of research and long-term testing, which consistently confirms its reliability and performance. The glass is subjected to rigorous quality checks, ensuring that every sheet of toughened glass adheres to essential safety and performance benchmarks. These quality assurance protocols are critical in preserving the material's reputation and reliability across varied applications.

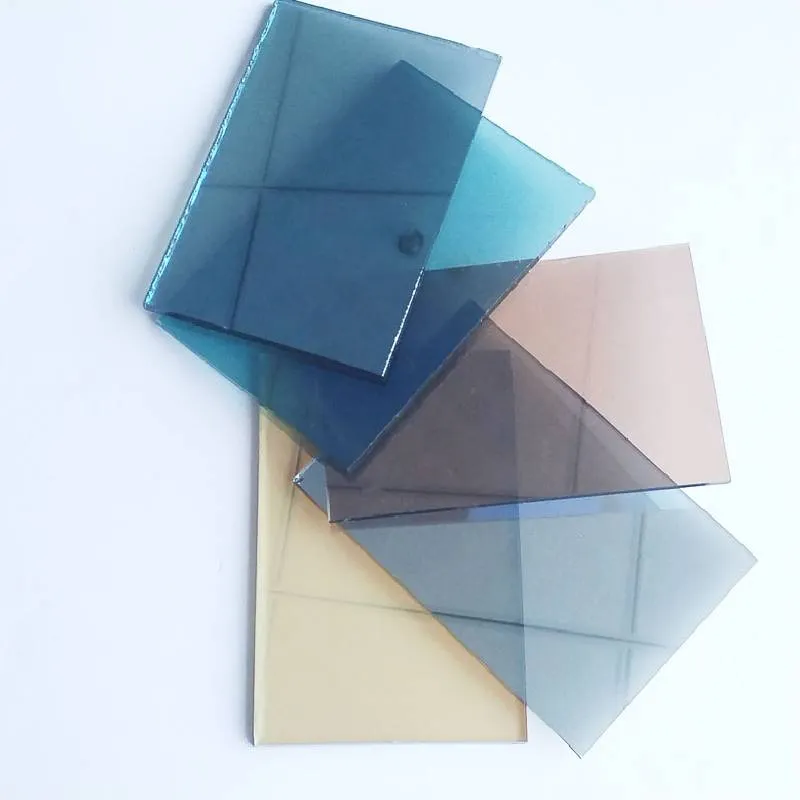

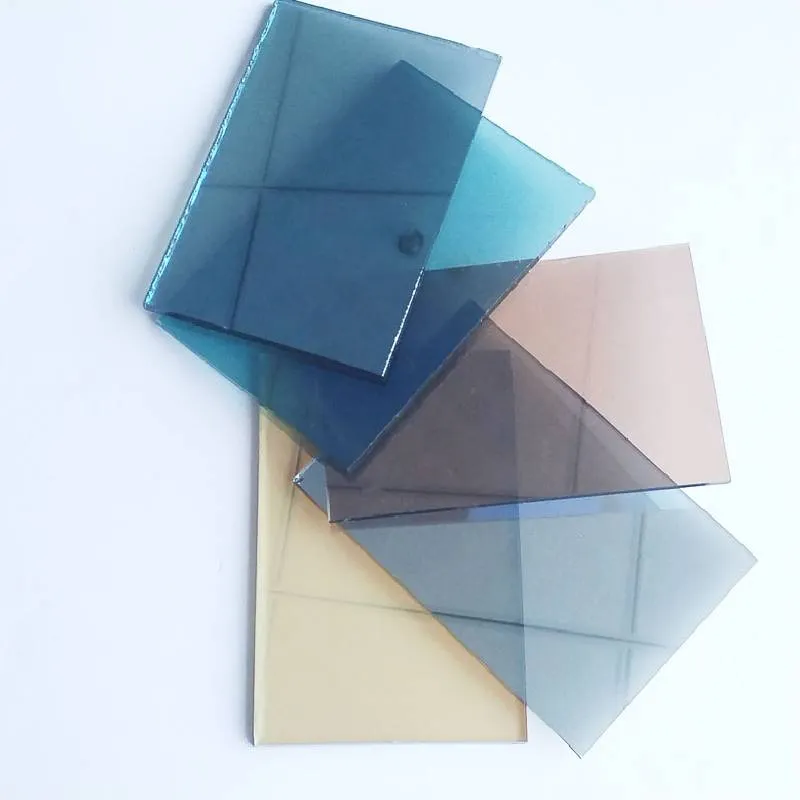

toughened glass making

Trustworthiness in toughened glass production extends beyond the product itself to the manufacturers and suppliers who produce it. This industry thrives on transparency and accountability, with suppliers often providing comprehensive guarantees and after-sales support to reinforce customer confidence. Partnerships between toughened glass manufacturers and independent safety-certification bodies further bolster consumer trust, providing undeniable proof of compliance with global safety standards.

In recent years, innovation has further propelled the relevance of toughened glass. Technological advancements have introduced new possibilities, such as incorporating smart functionalities like switchable glass technology and scratch-resistant coatings. These features enhance the adaptability of toughened glass, making it a versatile element in modern design that caters to both aesthetic and functional requirements.

In a marketplace that demands high standards for safety, efficiency, and aesthetic quality, toughened glass represents a blend of state-of-the-art technology and traditional craftsmanship. The refined process of toughened glass making not only produces robust and safe glass products but does so with a commitment to sustainability and efficiency. As industries continue to evolve, so too does the methodology behind toughened glass production, ensuring it remains a cornerstone in contemporary material science and engineering.

In conclusion, toughened glass stands as a testament to human ingenuity in material innovation. Its production process, distinguished by precision and technology, guarantees unmatched strength, safety, and adaptability. The expertise of industry professionals ensures that toughened glass remains at the forefront of material choice in safety-focused sectors. As we look to the future, toughened glass will undoubtedly continue to shape the landscape of design and architecture, offering both function and style with unwavering reliability.

Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu