Toughened Glass Manufacturing Plant An Insight into Production and Innovation

Toughened glass, known for its enhanced strength and safety features, has become a critical component in various industries, including construction, automotive, and electronics. The manufacturing process of toughened glass is intricate, requiring precision and technology to ensure the final product meets the high standards expected in today’s market. A toughened glass manufacturing plant incorporates advanced machinery, skilled personnel, and rigorous quality control measures to produce this vital material.

The Production Process

The journey of toughened glass begins with the selection of the right raw materials. Float glass, known for its uniform thickness and clarity, is typically used as the starting point. The manufacturing process starts by cutting the float glass into specific dimensions based on client requirements. The glass is then subjected to a rigorous cleaning process to eliminate any impurities or contaminants that could affect the quality of the final product.

After the initial preparations, the glass enters the toughening process. This involves heating the glass to temperatures around 600 degrees Celsius in a specialized furnace. This step is critical, as it alters the internal structure of the glass, making it much stronger than regular glass. The heating stage is followed by a rapid cooling process known as quenching. The glass is exposed to cold air blasts, which cool the surface quickly while the interior remains hot, creating compressive stresses that greatly enhance its strength.

The entire cycle requires precise control of both temperature and duration, as any deviation can result in defects or reduced strength. Therefore, modern manufacturing plants utilize state-of-the-art technology, including computerized monitoring and control systems, to ensure the process is consistently optimized.

Quality Control Measures

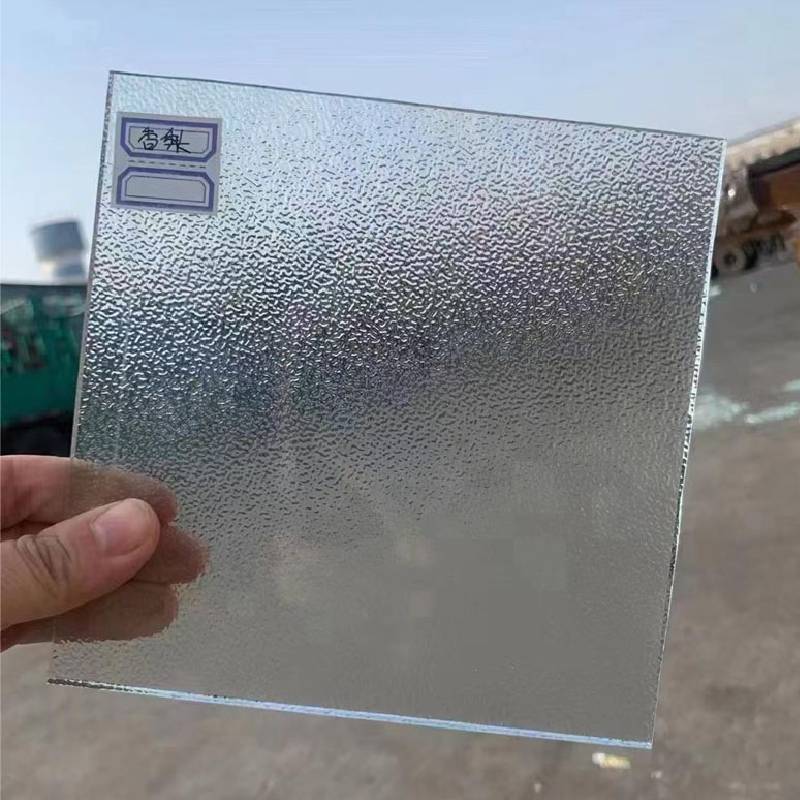

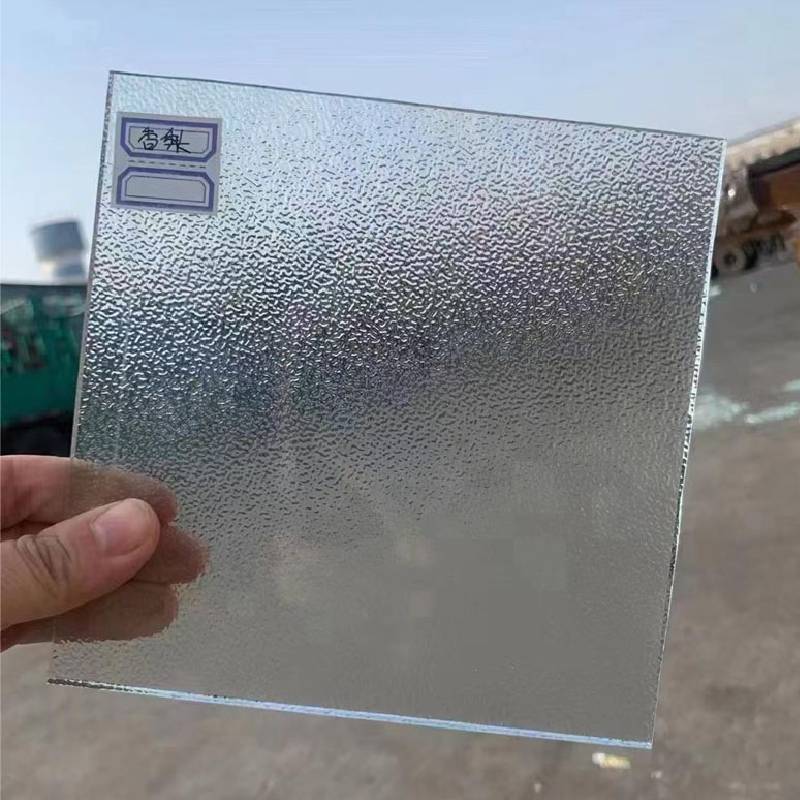

toughened glass manufacturing plant

Quality control is vital in the toughened glass manufacturing process. Various tests are conducted to ensure that the glass meets safety and strength standards. Some common assessments include checking for thermal stress, thickness uniformity, and optical clarity. Additionally, production plants often implement random sampling inspections to detect any flaws in the production batch. This comprehensive approach not only enhances the reliability of the product but also boosts customer confidence in the brand.

Environmental Considerations

In today’s environmentally-conscious world, toughened glass manufacturing plants have also taken significant strides towards sustainability. Many plants employ recycling processes to minimize waste. Scrap glass generated during cutting and production is often reintroduced into the manufacturing cycle, reducing the need for new raw materials. Furthermore, modern furnaces are designed to be energy-efficient, utilizing renewable energy sources wherever possible to lessen the carbon footprint of production.

Innovation in Toughened Glass

Innovation is at the heart of toughened glass manufacturing. The industry continually seeks to develop new techniques and products that enhance the functionality and aesthetics of glass. For instance, advances in glass coating technologies have led to anti-reflective and self-cleaning surfaces that appeal to both consumers and architects. Furthermore, the integration of smart technologies into glass—such as embedded sensors and variable opacity—allows for new applications in smart building design.

Conclusion

The toughened glass manufacturing plant represents a blend of tradition and modern technology. As construction and design continue to evolve, the demand for safe, durable, and aesthetically pleasing glass will remain high. By focusing on quality production, implementing stringent quality control measures, and embracing sustainability and innovation, these plants are poised to meet the challenges of the future. As we move forward, toughened glass will undoubtedly play a significant role in shaping our environments, providing not only functionality but also enhancing our lives through design and innovation. The commitment of manufacturers to enhance their processes will ensure that toughened glass remains a cornerstone of modern construction and design for years to come.

Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu