- Introduction to What Does Low Iron Glass Mean and Core Related Terms

- Technical Advantages of Low Iron Glass Over Regular Glass

- Comparing Low Iron and Tempered Glass: Data and Manufacturer Insights

- Distinctive Appearance: What Does Rain Glass Look Like?

- Tailored Solutions: Custom Low Iron Glass Applications

- Real-World Use Cases: Successful Low Iron Glass Integration

- What Does Low Iron Glass Mean for Innovation in Modern Design?

(what does low iron glass mean)

Introduction to What Does Low Iron Glass Mean and Core Related Terms

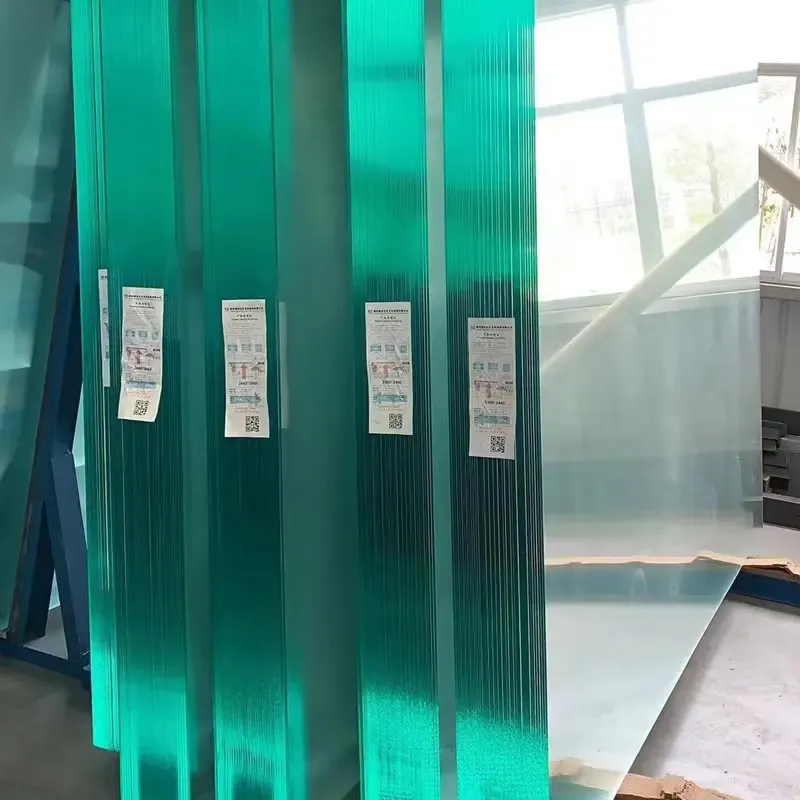

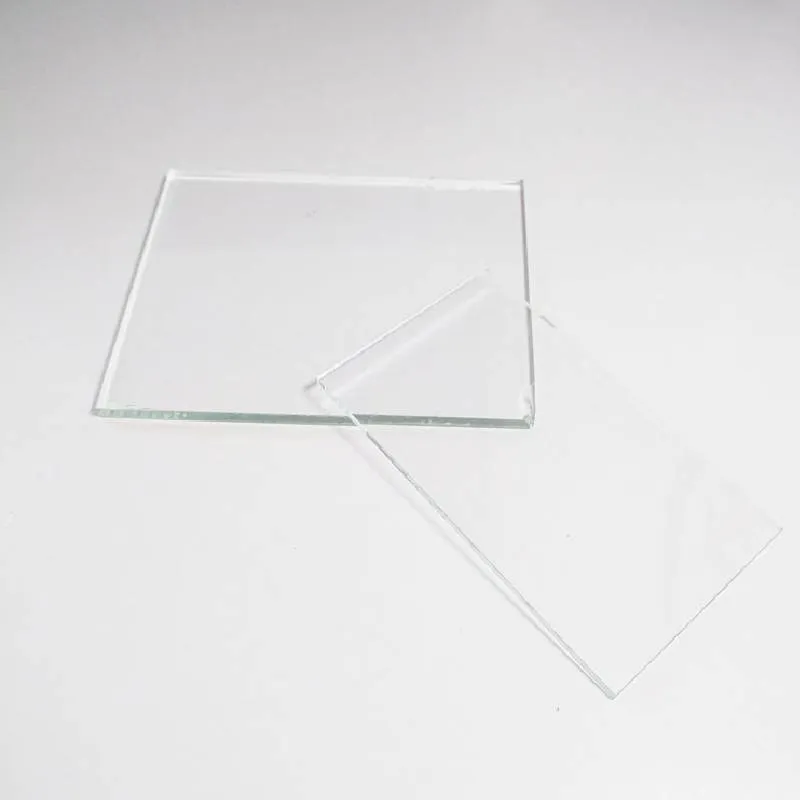

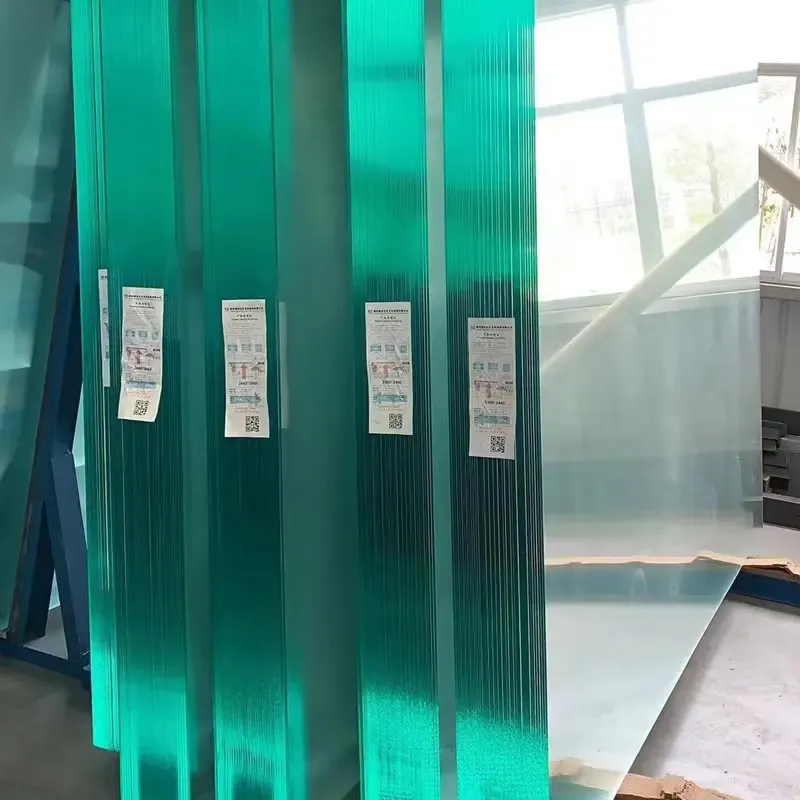

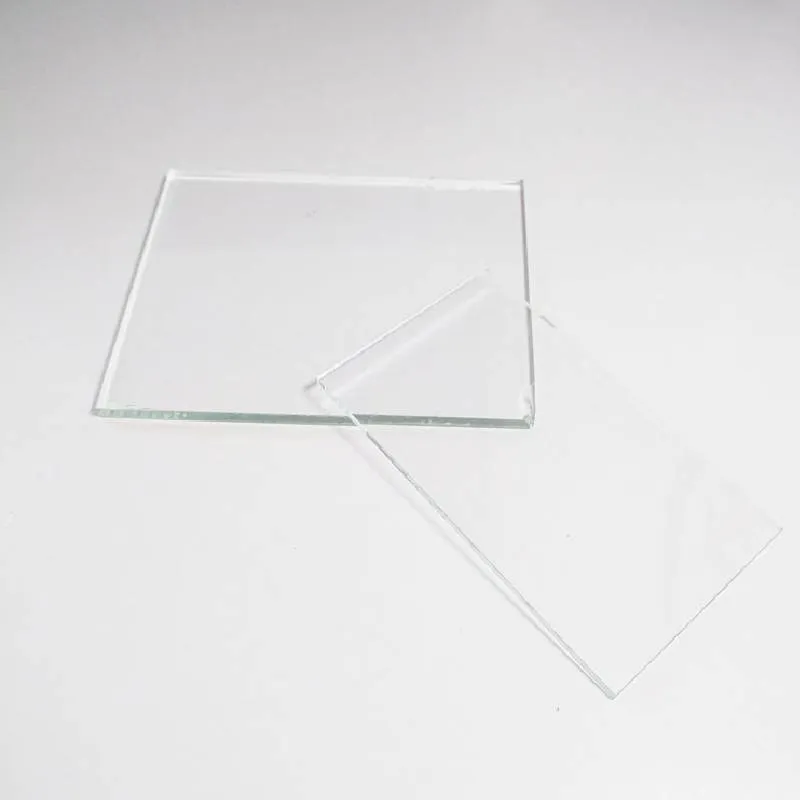

Understanding what does low iron glass mean

is fundamental when considering glass selection for architectural, display, or decorative purposes. Low iron glass, also known as extra-clear glass, is distinct because it is manufactured with reduced iron content, allowing for greater light transmission and clarity compared to standard clear glass. This lower iron concentration prevents the typical greenish tint often present in conventional glass products. In contrast, tempered glass refers to glass that has undergone special heat-treatment to improve its strength and safety characteristics, while rain glass is a decorative glass product, noticeable by its textured surface mimicking falling rain. Understanding these key differences broadens the perspective when making informed decisions for glass usage.

Technical Advantages of Low Iron Glass Over Regular Glass

Low iron glass stands out not only aesthetically but also functionally. Its transmittance rate can reach up to 91-92%, compared to the typical 84-86% in standard float glass, creating a visibly clearer and brighter result. This property is invaluable in applications like solar panels, high-end architecture, retail displays, and aquariums. Furthermore, with iron content reduced to approximately 0.01-0.02%—compared to around 0.1% in standard glass—low iron glass eliminates unwanted coloration and ensures true-to-source color rendering. This clarity is especially critical in contemporary design trends prioritizing openness, natural lighting, and color accuracy. Beyond visual superiority, low iron glass can also be laminated, toughened, or coated just like conventional glass, maintaining safety and specialized performance.

Comparing Low Iron and Tempered Glass: Data and Manufacturer Insights

Evaluating the properties and offerings from top suppliers provides clear context for selecting the appropriate glass product. Below is a data-driven comparison table based on leading manufacturer specifications:

| Property / Attribute |

Low Iron Glass |

Tempered Glass |

Standard Clear Glass |

| Light Transmittance (%) |

91-92% |

84-90% (dependent on base glass) |

84-86% |

| Iron Content (%) |

0.01-0.02 |

0.1 (regular), 0.01-0.02 (when low iron base) |

0.1 |

| Color |

Ultra-clear, color-neutral |

Standard or ultra-clear (if low iron) |

Greenish tint present |

| Strength |

Dependent on processing |

4-5x stronger than annealed |

Standard |

| Available Thickness (mm) |

3-25 |

3-19 |

3-25 |

| Major Brands |

Guardian UltraClear, Saint-Gobain Diamant, Pilkington Optiwhite |

PPG, AGC, Saint-Gobain |

Generic float glass |

| Best Use Cases |

Facade, display, solar, aquarium |

Safety glazing, shower doors, partitions |

Windows, basic glazing |

It's vital to note that both low iron and tempered glass can be combined: when safety and clarity are needed simultaneously—such as in high-end storefronts—manufacturers offer low iron tempered glass. Industry leaders like Guardian, Saint-Gobain, and Pilkington set the global standards for low iron glass with highly consistent iron removal processes and rigorous quality control, ensuring every panel delivers optical precision.

Distinctive Appearance: What Does Rain Glass Look Like?

Rain glass differs substantially in both appearance and function from low iron glass. While low iron glass is prized for its clarity, rain glass features a visually textured pattern designed to resemble cascading water droplets or rainfall. This surface detail not only serves decorative purposes but also provides privacy by diffusing light and obscuring direct lines of sight. The orientation of rain glass—vertical versus horizontal—can alter its impact in interiors or exterior settings. Market data reveals that rain glass is most commonly used in bathroom enclosures, cabinet doors, and certain window applications, with its ability to scatter light effectively reducing glare and softening harsh sunlight. In design comparisons, rain glass typically transmits slightly less light, often in the 75-80% range, due to patterning, but delivers unrivaled ambiance in spaces where privacy and decorative style are desired.

Tailored Solutions: Custom Low Iron Glass Applications

Customization is a pivotal advantage of low iron glass. Architects and designers increasingly specify bespoke panel sizes, edge profiles, and coatings—including anti-reflective and solar control layers—to suit project needs. Manufacturers cater to a wide array of requirements:

- Thick, ultra-clear casings for aquarium panels, display cases, and luxury balustrades

- Oversized façade applications for modern skyscrapers and curtain walls

- Specialty lamination for sound reduction and safety in high-traffic environments

- Precision-cut or shaped components for museum or retail presentations requiring distortion-free transparency

Industry estimates indicate a

20% annual growth in demand for tailored low iron glass projects in premium commercial and residential markets. This surge is fueled by clients seeking differentiation through maximized daylighting and elegant, color-true visual connections to outdoors. From digitally printed graphics to switchable privacy technologies embedded in low iron panels, customization is limited mainly by imagination and logistics, not material constraints.

Real-World Use Cases: Successful Low Iron Glass Integration

Examining practical examples illustrates the full spectrum of low iron glass utility. Consider the Apple Park Visitor Center in Cupertino, which employs expansive low iron glass walls to achieve seamless indoor-outdoor transitions, supporting the brand’s minimalist architectural ethos. Similarly, the Dubai Frame's observation decks maximize skyline views with low iron glass, enabling clear vistas even in challenging sunlight. On a smaller scale, luxury jewelry retailers use low iron display cases to eliminate color distortion, crucial for the accurate presentation of gemstones. In art galleries and museums, preserving faithful art representation—and protecting against UV degradation—is possible due to specialized low iron glass with added protective coatings. These projects highlight not just aesthetic but commercial and functional gains: increased traffic, longer dwell times, and a measurable lift in perceived space value—sometimes as much as 15-25% higher than conventional builds.

What Does Low Iron Glass Mean for Innovation in Modern Design?

The question of what does low iron glass mean for modern development extends far beyond mere material specification. In a world driven by technological advancement and evolving aesthetic standards, low iron glass enables design possibilities that spark innovation. Data shows that projects incorporating low iron glass—either alone or in combination with technologies like double-glazing or photovoltaic layers—outperform traditional builds in both energy efficiency and occupant satisfaction. The transparency and purity of low iron glass foster a unique connection to the outside world, fulfilling human-centric design objectives while supporting sustainable urban environments. As glass manufacturing continues to evolve, expect further enhancements in clarity, strength, and customization, helping shape iconic, enduring spaces in architecture, retail, and beyond.

(what does low iron glass mean)

FAQS on what does low iron glass mean

Q: What does low iron glass mean?

A: Low iron glass is a type of glass that has reduced iron content compared to standard glass, resulting in higher clarity and less greenish tint. It is commonly used in applications requiring maximum transparency and color accuracy.

Q: Why choose low iron glass over regular glass?

A: Low iron glass is chosen for its enhanced clarity and true color representation, making it ideal for displays, shower enclosures, and architectural features. Unlike regular glass, it does not give off a noticeable green hue.

Q: Tempered glass—what does it mean?

A: Tempered glass is specially heat-treated to increase its strength and safety. When broken, it shatters into small, blunt pieces rather than sharp shards, reducing injury risk.

Q: What does rain glass look like?

A: Rain glass features a textured surface that mimics the appearance of falling rain. It provides privacy while still allowing light to pass through and is often used in shower doors and windows.

Q: Can low iron glass be tempered for safety?

A: Yes, low iron glass can undergo the tempering process just like regular glass. This makes it both highly transparent and safe for use in demanding settings such as doors and facades.

Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu