Window panes, mirrors or designer furniture: glass is a diverse material and we encounter it in many areas of everyday life. Float glass is used in almost all cases. This is flat glass, which is produced in a so-called float process and has a particularly smooth surface. Read all the important information about the manufacture and properties of float glass and special float glasses such as Optiwhite or safety glass here.

What is Floatglass?

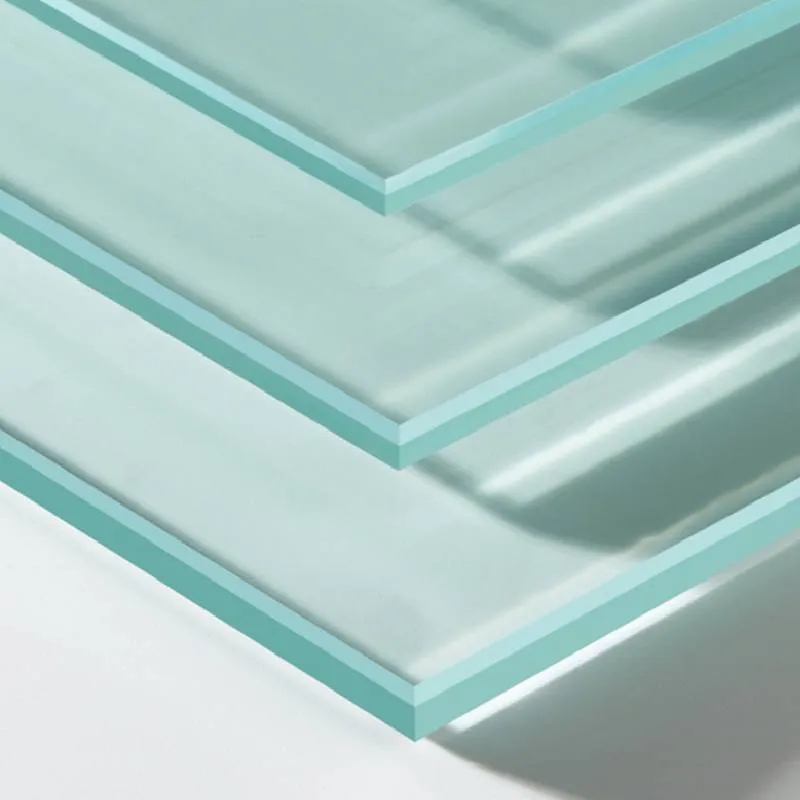

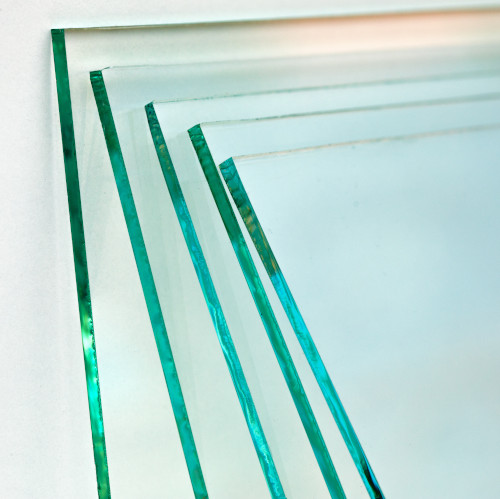

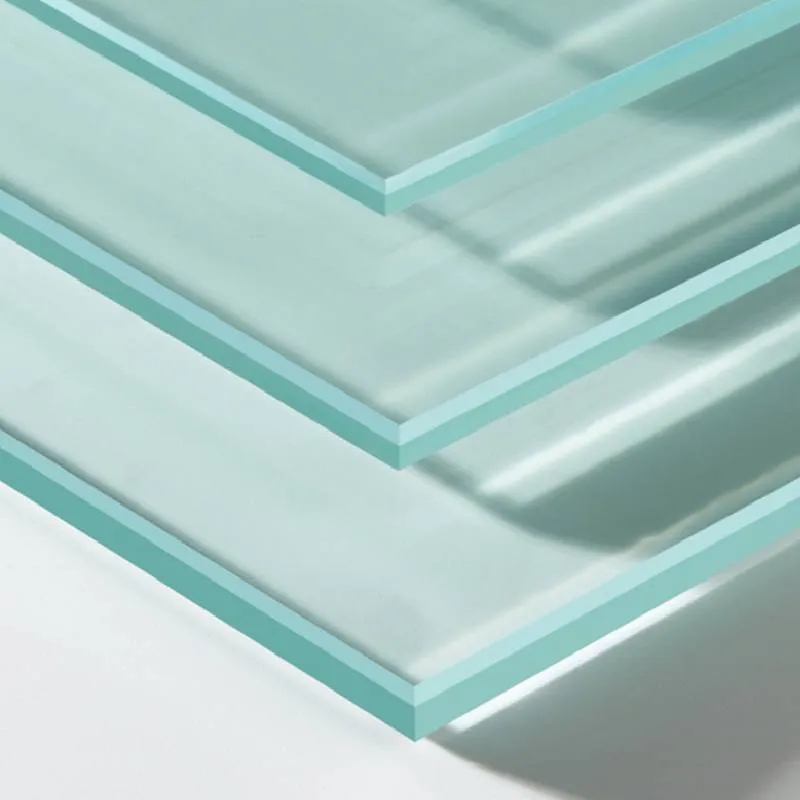

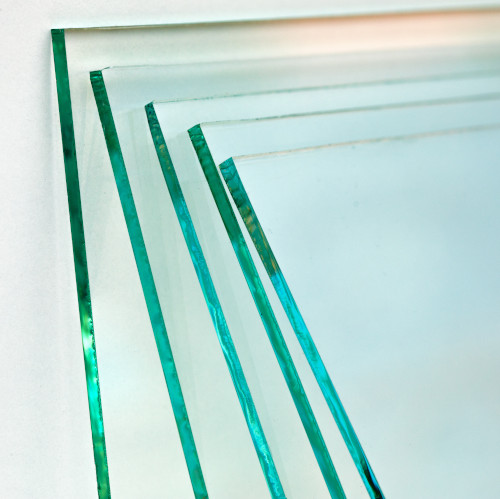

Float glass is a so-called flat glass, which is produced in a float glass process. To do this, the molten glass is applied to a bath of liquid tin. Since the glass is lighter than tin, it floats on the surface and spreads out completely evenly.

The result is glass with an immaculately smooth surface that is free of air pockets (such as bubbles or streaks). Because of these advantages, the float glass process has largely become established in the manufacture of flat glass.

Design furniture made of float glass: classic, noble

Float glass is also valued in furniture design: with its immaculately smooth surface and crystal-clear transparency, it is ideal for the production of fine glass furniture. The typical float glass shimmers slightly greenish and has a clear green to green-black color at the edges.

Glass furniture made of classic float glass exudes an elegance that goes particularly well with an upscale furnishing style. Are you looking for a fresh, modern touch? Then it is advisable to use glass furniture made of white glass, for example the extra light Optiwhite glass.

How long has the float glass been in existence?

Until the 1960s, flat glass was manufactured using other methods, such as pulling, rolling or casting. The resulting glass, however, always had a slight curl or drawing strip, so that it did not appear completely clear.

In 1959, the British engineer Alastair Pilkington introduced the float glass process for the first time, and industrial float glass production began in the mid-1960s. Since then, the float glass method has increasingly replaced all other processes.

Float glass: properties and use

As already mentioned, a major advantage of float glass is its completely even surface. In contrast to previous manufacturing processes, glass can be produced in the float process, which allows a clear, undistorted view.

Other properties of float glass:

- robust against scratches

- weight: approx.2.5 kilograms per square meter and millimeter of glass thickness

- plane-parallel surfaces: Both sides of the glass surface are completely flat and parallel to each other.

- color: Float glass usually has a slightly greenish color, which is particularly visible on the edges. For lighter glass, special raw materials low in iron oxide are used (see also the point "Float glass vs. white glass" below).

- high light transmission: conventional float glass (single glass, glass thickness of 3-10 millimeters) has a light transmission of approx. 85-90%, with white glass the value is even higher.

- resistance to temperature changes: It is around 40 Kelvin (with simple glass without safety treatment), which means that float glass can withstand rapid temperature changes in the range of up to 40 Kelvin.

These features and a comparatively inexpensive manufacturing process have led to float glass being used in a variety of ways today. Around 95% of flat glass is float glass.

Among other things, it is used for:

- Windows

- Mirrors

- Car Windows

- Facade glazing

- Glashäuser

- Glass furniture

- v. m.

In many cases, float glasses are not processed as single panes: Multiple glazing made from several float glass panes is mostly used for windows, doors and facades.

Through special treatment, the flat glass can also be processed into safety, laminated and insulating glass (see the item "Float glass as safety glass").

The manufacture of float glass in detail

Let's now take a closer look at the production of float glass in Detail

1. Raw materials

In the first step, the individual raw materials from which the glass is later made are mixed and melted. The following raw materials are required for glass production:

- Quartz sand

- Soda (sodium carbonate)

- dolomite

- Lime (calcium carbonate)

In most cases, 10-15% of recycled, cleaned glass shards are also added. The so-called batch is created from these “ingredients” in the melting furnace.

2. Float process

In the next step, the batch is passed to a bath of liquid tin at a temperature of approx. 1100 ° C. Because of their different density (the glass mixture is about two thirds lighter than tin), the two substances do not mix. The glass floats at the top and spreads out very evenly in all directions. The characteristic smooth surface is formed by the surface tension of the tin and the liquid glass.

Incidentally, the float glass process is a continuous process - once it is started, it runs continuously day and night as long as the plant is in operation. Glass mixture is permanently filled in on one side, and the cooled glass ribbon is pulled out and cut on the other side.

3. Cooling and cutting

The glass is then cooled down slowly and without tension. As soon as it is “only” 600 ° C hot, the glass ribbon can be lifted off the tin bath. The glass cools further in an additional cooling furnace. It is then checked for quality, washed and cut to the desired sizes.

Manufacture of various glass thicknesses

The thickness of the glass depends on how fast the rollers move in the cooling area. The faster these rollers are, the thinner the glass plate becomes. Usually an additional production step of stretching or upsetting is installed to control the glass thickness. The processing then takes place as follows:

- Spread the liquid glass mass on the tin

- Cool the glass to around 700 ° C

- Glass ribbon is caught by rolls.

- The glass ribbon is heated again to 850 ° C.

- Stretch or compress the glass ribbon (depending on the speed of the rolls) to the required thickness

- Final cooling

Float glass as safety glass

The float glass is processed into safety glass for a large number of uses. These are panes of glass that crumble into many small parts if broken, or that do not even fall apart. This minimizes the risk of injuries or serves as burglary protection.

Two important key figures for safety glass

With regard to the characteristics of safety glass, two terms often appear, which we briefly explain:

- Flexural strength: This is the maximum bending stress that a component can withstand before it breaks. They are given in Newtons per square millimeter (N / mm²). Untreated float glass has a flexural strength of approximately 45 N / mm².

- Resistance to temperature changes: This is the temperature difference at which a material or component withstands a quick change without causing damage. They are given in Kelvin (K). For untreated float glass, the thermal shock resistance is 40 K.

One differentiates among other things the toughened safety glass (ESG), the laminated safety glass (VSG) and the partially tempered glass (TVG):

ESG float glass

Simple float glass without safety treatment breaks into pieces of fragments that pose a great risk of injury. The fracture pattern of ESG float glass looks different: Here the glass breaks down into many small, blunt crumbs. Existing ESG has an increased flexural strength (at least 120 N / mm²) - it also generally belongs to safer shocks and stands - and an increased resistance to temperature changes (approx. 200 K).

The glass is heated to a temperature of more than 600 ° C and then suddenly cooled again. This means an internal stress in the glass and it comes to the affected properties.

VSG float glass

Laminated safety glass (VSG) does not only consist of one pane of glass, but of several panes glued together. In between there is a tear-resistant plastic film.

The result: the glass can break, but the glass fragments do not fall to the ground. The fragments adhere to the plastic film and the glazed opening remains closed. The VSG float glass thus offers, for example, increased protection against burglars, and roof glazing and windscreens are usually made of VSG.

TVG float glass

The partially tempered glass (TVG) is processed in a similar way to single-pane safety glass, using a thermal tempering process (heating and cooling the pane). However, cooling down is slower. The TVG float glass, with its bending strength (70 Nm / mm²) and resistance to temperature changes (100 K), lies between the normal float glass and the ESG float glass.

TVG float glass is mostly used as the basis for laminated safety glass. Because it is more stable than ordinary float glass, but forms larger fragments than the fully tempered glass. In the case of laminated safety glass made of TVG, a high residual load-bearing capacity of the pane remains when broken, which can be important for fall protection, for example.

Float glass: an integral part of everyday life

Float glass panes surround us constantly, whether we are aware of it or not: whether we look through the windshield in the car, sunbathe in the glazed veranda or admire fine porcelain in a glass display case. Because the float glass process can be used to produce mirror-flat glass in an efficient manner that allows crystal-clear viewing.

Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu