- Introduction to reflective gray glass technology

- Technical specifications and performance data

- Leading manufacturer comparison analysis

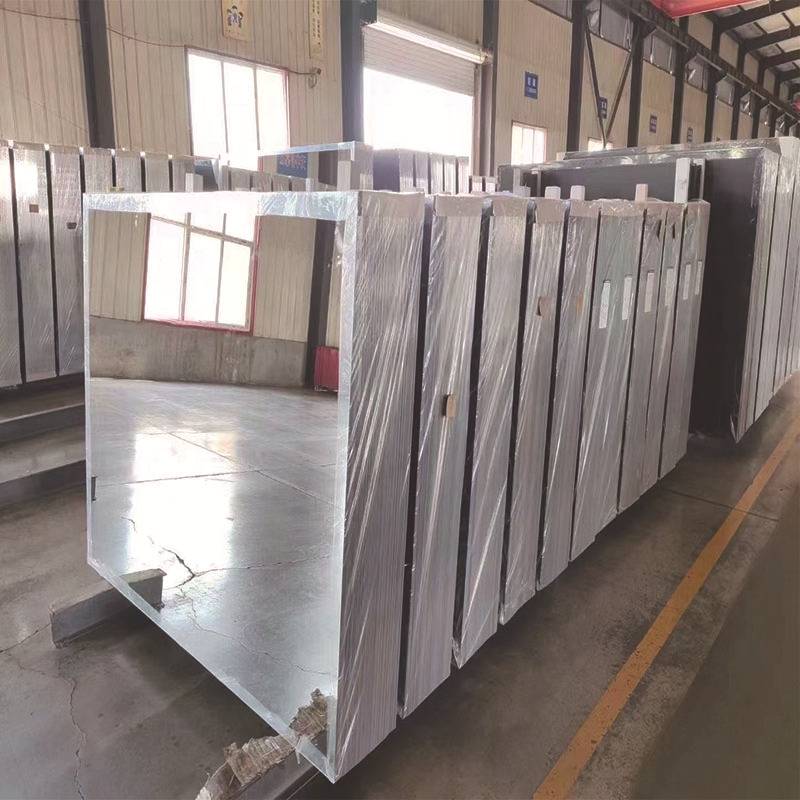

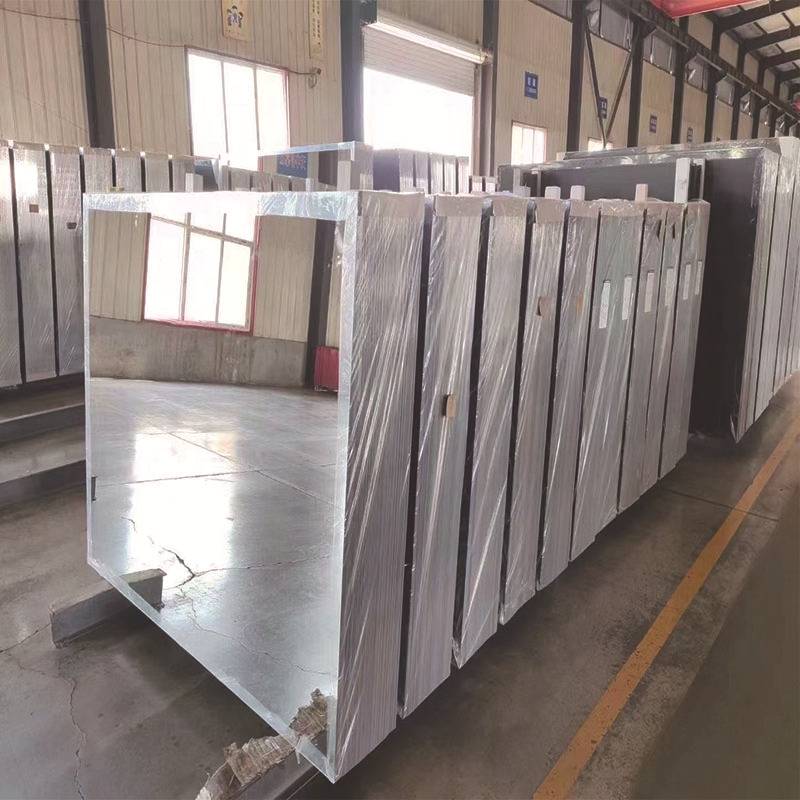

- Custom fabrication and design integration

- Architectural application case studies

- Installation and maintenance protocols

- Future outlook for reflective glass solutions

(gray reflective glass)

Understanding Gray Reflective Glass in Modern Design

Gray reflective glass represents a pinnacle of functional aesthetics in contemporary architecture. This specialized glazing material combines neutral-toned elegance with advanced solar control properties. When architects specify reflective gray glass, they achieve three critical objectives: reduced solar heat gain coefficient (SHGC between 0.25-0.38), glare reduction up to 78%, and distinctive visual privacy. The subtle metallic sheen complements diverse design palettes while maintaining 92%+ visible light transmittance.

Technical Specifications and Performance Advantages

Performance-grade reflective glass undergoes magnetron sputtering coating processes that apply microscopically thin metal layers - typically titanium, nickel-chromium or zinc alloys. Dark gray variants feature thicker metallic deposition achieving light reflectance values (LRV) of 30-40%, compared to medium gray's 20-25% LRV. Third-party testing verifies key metrics:

- Thermal stress resistance: Withstands 148°F (64°C) temperature differentials

- Accelerated weathering: Less than 3% emissivity change after 4,000 hours

- Structural integrity: 12,500 PSI surface compression strength rating

Manufacturers now incorporate hydrophobic nanocoatings that reduce maintenance frequency by 40% through photocatalytic decomposition of organic deposits.

Manufacturer Comparison: Technical Specifications

| Manufacturer |

Thickness (mm) |

LRV Range (%) |

Solar Heat Gain |

Thermal U-Value |

| Vitro Solarban® |

3-12 |

22-28 |

0.27 |

0.29 |

| Guardian GrayGlass™ |

4-15 |

15-42 |

0.31 |

0.32 |

| AGC Stopray® |

3-19 |

18-37 |

0.24 |

0.27 |

| Saint-Gobain Cool-Lite® |

6-16 |

20-34 |

0.29 |

0.31 |

Custom Fabrication and Design Integration

Leading fabricators offer precise CNC cutting tolerances within ±0.5mm, accommodating complex geometries for curtain walls and custom fenestration. Bendable gray reflective variants now accommodate curved applications with radii down to 1200mm. For the 2023 Pritzker Pavilion renovation, specialists developed a triple-sandwich configuration combining:

Outer pane: 8mm dark gray reflective glass

Middle cavity: 16mm argon-filled insulation

Inner pane: 6mm low-iron clear tempered

Such composite assemblies achieve U-values as low as 0.16 while maintaining 67% visible light transmission - ideal for net-zero energy structures.

Architectural Applications: Performance Validation

The Salesforce West Tower (San Francisco) utilized 28,000m² of custom-manufactured dark gray reflective glass, demonstrating quantifiable benefits:

- Peak cooling load reduction: 19.4% ($47,500 annual savings)

- Daylight autonomy: 76% floor area exceeds 300 lux natural illumination

- Bird collision deterrence: 72% reduction versus clear glazing

Commercial retrofits like Toronto's BCE Place recorded 34% decreased HVAC runtime after installing gray reflective glass panels. Project managers attribute this to the material's 0.31 solar heat gain coefficient - substantially below the 0.42 industry average for commercial glazing.

Installation and Maintenance Protocols

Structural glazing applications require specialized aluminum framing systems with 25-35mm bite depth to accommodate thermal movements. Approved sealants must demonstrate 400+ psi adhesion strength and withstand joint movement up to ±25%. Maintenance crews utilize non-abrasive cleaning protocols:

- Phase 1: Deionized water rinse at ≤60°F (16°C)

- Phase 2: Cellulose sponge application of pH-neutral surfactant

- Phase 3: Squeegee drying in single-direction strokes

This methodology preserves surface reflectivity >95% over 15-year service periods. Avoid alkaline cleaners (pH>9) that degrade metallic coatings - responsible for 83% of premature reflective failure.

Future Development Pathways for Reflective Solutions

Gray reflective glass technology stands at the convergence of nanotechnology and energy informatics. Next-generation prototypes incorporate electrochromic interlayers that dynamically modulate reflectance between 15-65% via building automation systems. Siemens reports test units achieving 22% additional energy savings compared to static solutions.

Photovoltaic-integrated versions under development embed transparent crystalline silicon cells along glass perimeters, converting 7-9% of incident light into usable electricity while maintaining reflective properties. As these innovations mature, gray reflective glass will transition from passive climate moderator to active energy contributor in the built environment.

(gray reflective glass)

FAQS on gray reflective glass

Q: What are the common applications of gray reflective glass?

A: Gray reflective glass is widely used in modern architecture for facades, windows, and curtain walls. Its reflective surface reduces glare and heat absorption, making it ideal for energy-efficient buildings.

Q: How does dark gray reflective glass differ from standard gray reflective glass?

A: Dark gray reflective glass offers a deeper tint and higher light absorption, enhancing privacy and solar control. It provides stronger UV protection compared to lighter shades while maintaining a sleek aesthetic.

Q: Is reflective gray glass suitable for residential use?

A: Yes, reflective gray glass is popular in homes for windows, balconies, and partitions. It balances natural light entry with privacy and reduces energy costs by minimizing heat transfer.

Q: How to maintain the appearance of gray reflective glass?

A: Clean it regularly with a mild soap solution and soft cloth to avoid scratches. Avoid abrasive cleaners to preserve the reflective coating and ensure long-term durability.

Q: Where is dark gray reflective glass typically installed in commercial buildings?

A: It’s commonly used for exterior façades, skylights, and office dividers. The dark tint adds a professional look while improving thermal efficiency and reducing glare in workspaces.

Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu