The tempered laminated glass industry has been revolutionizing the architectural and automotive sectors with its innovative solutions that blend safety, aesthetics, and functionality. Understanding the intricate aspects of tempered laminated glass and the manufacturers behind it is crucial for stakeholders looking to make informed decisions.

Tempered laminated glass is a hybrid material that offers superior strength, safety, and versatility. This glass comprises two or more layers of tempered glass, bonded together with an interlayer, usually polyvinyl butyral (PVB) or ethylene-vinyl acetate (EVA). The tempering process involves heating the glass to over 600°C and then rapidly cooling it, which makes it four to five times stronger than standard glass.

The first aspect to consider when evaluating manufacturers is their production capacity and technological expertise. Leading tempered laminated glass manufacturers invest heavily in cutting-edge technologies to enhance the quality and performance of their products. These companies utilize advanced techniques such as computer-aided design (CAD) and precision engineering to produce glass with unparalleled clarity and durability. Furthermore, they ensure compliance with international standards, such as the EN 12543 or ANSI Z97.1 safety codes, which assure product reliability and customer trust.

Another crucial factor is the manufacturer’s commitment to sustainability. Top-tier manufacturers employ eco-friendly production processes, reducing carbon footprint and waste. They use energy-efficient furnaces and recycle water and raw materials, supporting global efforts toward sustainable development. Clients often seek manufacturers who proactively adopt green practices, thereby enhancing their project's environmental credentials.

Customer service excellence is a hallmark of reputable tempered laminated glass manufacturers. These companies provide tailored solutions to meet specific project needs. Whether for skyscrapers’ façades, automotive windshields, or artistic installations, they offer customization options in terms of thickness, color, size, and finishes. Exceptional after-sales support, including installation guidance and maintenance advice, also distinguishes top manufacturers in this competitive field.

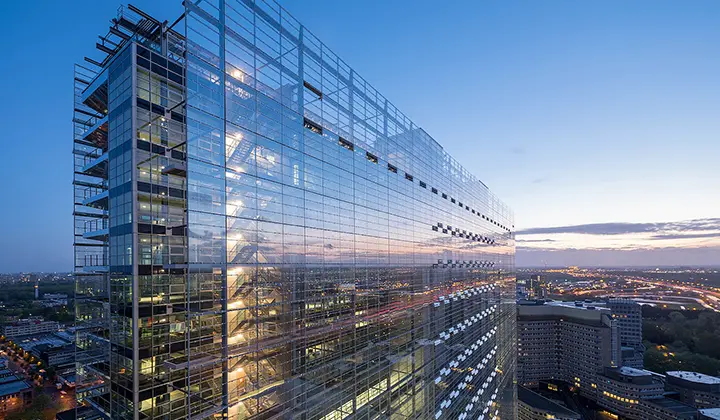

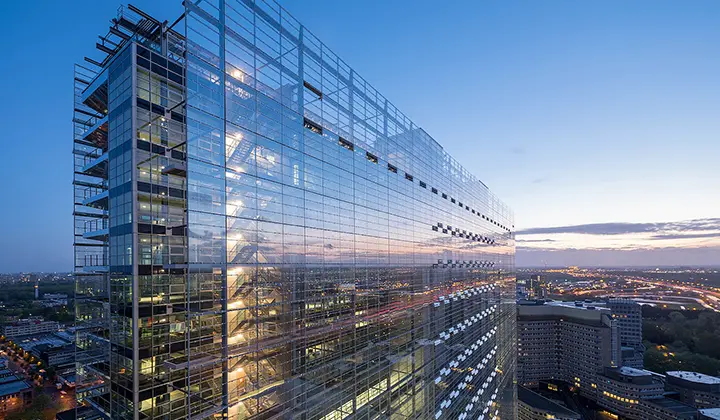

Experience and expertise are vital indicators of a manufacturer’s capability. Established companies with decades of experience bring a wealth of knowledge in overcoming engineering challenges and innovating design processes. They foster partnerships with architects, engineers, and designers, contributing to groundbreaking projects worldwide. Their expertise reflects in the successful completion of high-profile projects, serving as a testament to their authority in the industry.

tempered laminated glass manufacturers

Innovative tempered laminated glass manufacturers continually explore new applications and improvements to product performance. For instance, innovations such as sound reduction layers, high-efficiency insulating coatings, and anti-reflective features are developed to meet contemporary architectural demands. These advances have made tempered laminated glass indispensable in modern construction, providing solutions that seamlessly integrate with smart building technologies.

It’s also crucial to assess a manufacturer’s certifications and industry recognitions. Accreditation by esteemed bodies, such as the International Organization for Standardization (ISO), signifies adherence to quality management systems and production excellence. Industry awards and recognition serve as further indicators of a manufacturer’s standing and credibility.

Security is another paramount consideration in selecting a tempered laminated glass manufacturer. The interlayer in laminated glass keeps the sheet intact even when shattered, adding a layer of security in environments prone to impacts or intrusions. Many manufacturers offer bullet-resistant or blast-proof variants, which are vital in high-risk environments such as banks and government buildings.

The global participation and presence of a tempered laminated glass manufacturer can determine accessibility and logistical efficiency. Manufacturers with an expansive global network can provide quicker delivery times and better support. Being agile and responsive to global market needs affords them the ability to cater to diverse architectural styles and regulatory requirements across different countries.

In summary, identifying the right tempered laminated glass manufacturer involves a synthesis of examining their technological capabilities, sustainability initiatives, customer support, industry experience, innovation, certifications, security offerings, and global reach. Making well-informed decisions will ensure that your project benefits from glass solutions that not only fulfill aesthetic and functional requirements but also contribute to a sustainable and secure built environment. With the right partner, the potential applications for tempered laminated glass are virtually limitless.

Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu