- Overview of Tempered Glass Wholesale Industry

- Technical Advantages of Modern Tempered Glass

- Comparative Analysis of Top Manufacturers

- Custom Solutions for Diverse Applications

- Case Studies: Successful Projects Using Tempered Glass

- Quality Standards and Testing Protocols

- Why Partner with Reliable Tempered Glass Wholesale Manufacturers

(tempered glass wholesale manufacturers)

Tempered Glass Wholesale Manufacturers: Shaping the Industry

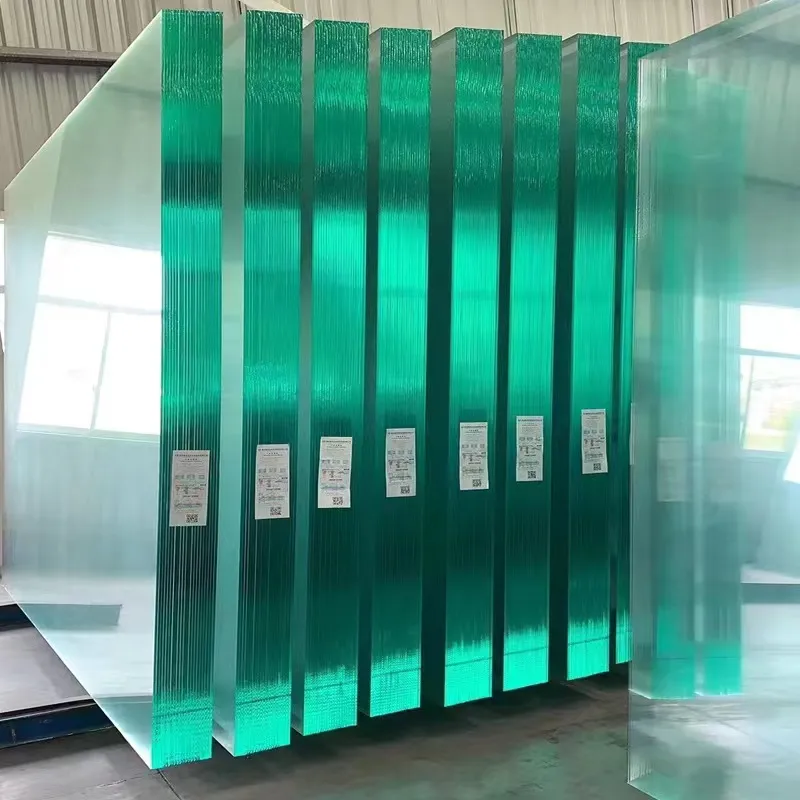

The global tempered glass market is projected to reach $76.3 billion by 2028, growing at a 6.8% CAGR. Leading tempered glass wholesale manufacturers

drive this expansion by supplying high-performance materials for construction, automotive, and electronics. With 73% of architectural projects now requiring tempered safety glass, bulk procurement through certified suppliers ensures cost efficiency and compliance with international safety standards.

Engineering Excellence in Tempered Glass Production

Advanced thermal toughening processes create surface compression strength of 10,000-15,000 psi, making tempered glass 4-5x stronger than annealed glass. Key technical specifications include:

- Thickness range: 3mm to 19mm (±0.2mm tolerance)

- Thermal resistance: Withstands 250°C temperature differentials

- Impact resistance: Survives 227g steel ball drops from 2m height

Manufacturer Comparison: Key Metrics

| Supplier | Price/sqft ($) | MOQ (sqft) | Lead Time | Certifications |

|---|

| Supplier A | 2.15 | 5,000 | 14 days | ISO 9001, CE |

| Supplier B | 1.98 | 10,000 | 21 days | SGCC, ANSI Z97.1 |

| Supplier C | 2.30 | 3,000 | 10 days | IGCC, EN 12150 |

Tailored Solutions for Specific Needs

Premium manufacturers offer customized processing including:

- Precision cutting (±0.5mm accuracy)

- Edge polishing (Arrised/Pencil/Flat edges)

- Special hole drilling (3mm to 50mm diameter)

- Silkscreen printing (1200 DPI resolution)

Real-World Applications and Performance Data

Project Case 1: High-rise building facade (Shanghai) used 85,000 sqft of 12mm tempered glass, reducing HVAC costs by 18% through improved thermal insulation.

Project Case 2: Automotive supplier achieved 40% weight reduction using 3mm tempered glass for sunroof assemblies.

Quality Assurance Protocols

All products undergo rigorous testing:

- Fragmentation test: 40-60 particles per 25cm² area

- Thermal shock resistance: 5 cycles from -40°C to 300°C

- Surface flatness: ≤0.1mm deviation over 1m length

Strategic Partnerships with Tempered Glass Wholesale Manufacturers

Establishing relationships with ISO-certified manufacturers ensures 12-18% cost savings on bulk orders. Leading suppliers now offer JIT delivery systems with 99.2% on-time performance rates, coupled with technical support for complex architectural installations.

(tempered glass wholesale manufacturers)

FAQS on tempered glass wholesale manufacturers

Q: How to choose reliable tempered glass wholesale manufacturers?

A: Look for certifications (e.g., ISO), customer reviews, and years of industry experience. Verify their production capacity and compliance with safety standards like ANSI or EN.

Q: Is purchasing tempered glass wholesale online secure?

A: Yes, if the supplier offers secure payment gateways and clear return policies. Always request samples and confirm shipping/insurance terms beforehand.

Q: What factors affect tempered glass price for wholesale orders?

A: Prices depend on thickness, size, customization, and order volume. Bulk orders typically lower per-unit costs, while coatings or edgework add expenses.

Q: How do tempered glass wholesale manufacturers ensure quality?

A: Reputable manufacturers use thermal tempering ovens and conduct stress tests. They provide compliance reports and may offer warranties against defects.

Q: Can tempered glass wholesale suppliers handle custom sizes/shapes?

A: Most manufacturers offer cutting, drilling, and edge-finishing services. Confirm design specifications, MOQs, and potential extra costs for complex patterns.

Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu