The Art and Science of Toughened Glass Making

Toughened glass, also known as tempered glass, is a remarkable material that has transformed various industries, from architecture to automotive engineering. Its strength and resilience stem from a precise manufacturing process that involves heating and rapid cooling, creating a product that can withstand greater stresses than standard glass. In this article, we will explore the methods of toughened glass making, its applications, benefits, and the science behind its impressive durability.

The Manufacturing Process

The production of toughened glass begins with the selection of high-quality raw materials, typically silica sand, soda ash, and limestone. These materials are melted together in a furnace at temperatures exceeding 1,400 degrees Celsius to form a homogeneous glass. Once the molten glass is produced, it is shaped into desired forms, often sheets or panels.

Once shaped, the glass undergoes the toughening process which is crucial to its performance. The glass is first heated in a tempering furnace to around 620 degrees Celsius, where it is maintained for a specific duration to ensure even heat distribution. After reaching the target temperature, the glass is rapidly cooled using powerful jets of cold air. This rapid cooling causes the outer surface of the glass to contract while the inner part remains expanded. As a result, a strong compression stress is developed on the surface of the glass, while the inner portion holds tension. This condition is what gives toughened glass its superior strength and thermal resistance.

Applications of Toughened Glass

Toughened glass is widely utilized across various sectors. In architecture, it is used for facades, windows, and doors, providing safety and aesthetic appeal. Its ability to withstand high impacts makes it an ideal choice for buildings located in hurricane-prone areas. In addition, many modern skyscrapers rely on toughened glass for their structures to reduce the risks associated with wind loads and flying debris.

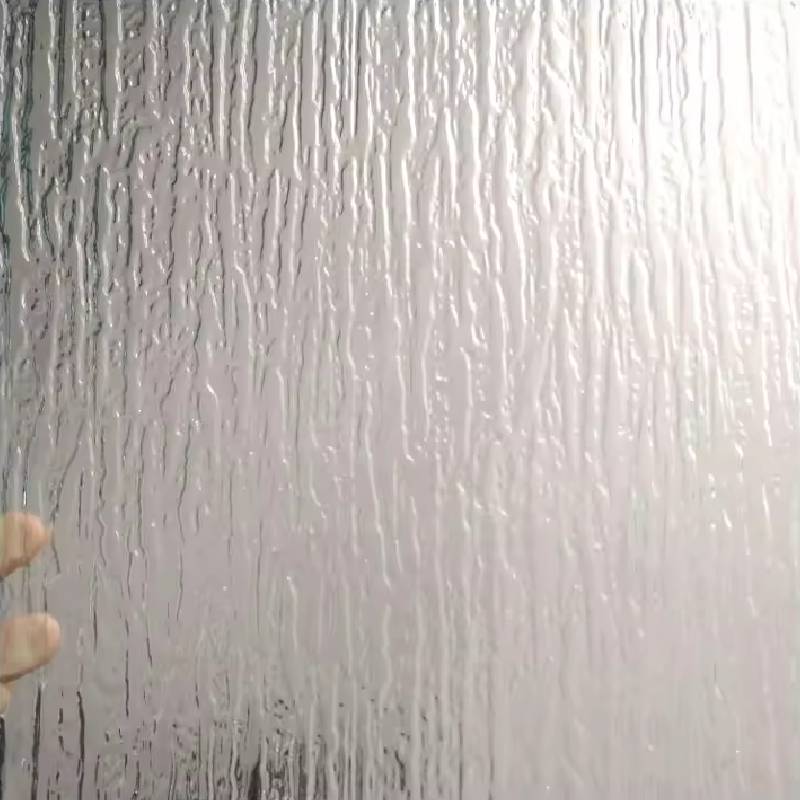

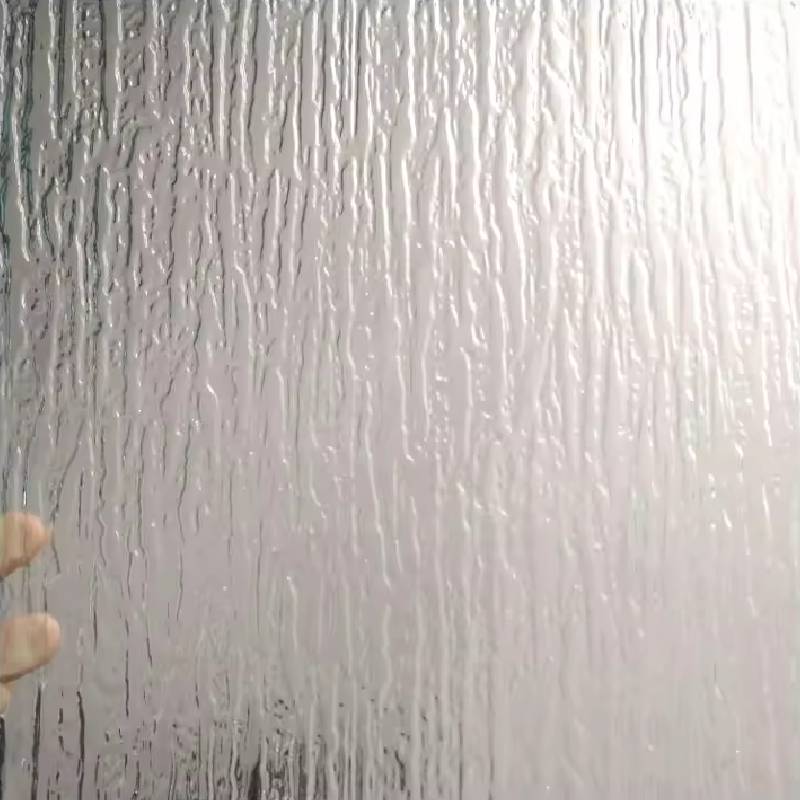

In the automotive industry, toughened glass is critical for side and rear windows. It shatters into small, blunt pieces rather than sharp shards, reducing the likelihood of injury during accidents. Furthermore, toughened glass is used in many appliances, such as ovens and shower doors, where heat resistance is crucial.

Another notable application is in the manufacturing of glass tabletops, display cases, and even mobile device screens, where durability is paramount

. The versatility of toughened glass means it can be found in a variety of products and environments, underscoring its importance in modern design and architecture.

toughened glass making

Benefits of Toughened Glass

The advantages of toughened glass are numerous. First and foremost is its incredible strength; toughened glass is approximately five to six times stronger than standard glass of the same thickness. This strength reduces the risk of breakage under stress, making it increasingly reliable for both everyday and extreme situations.

Additionally, toughened glass can withstand high temperature variations, making it a preferred choice in applications where thermal shock is a concern. This feature allows it to be used in settings that require significant changes in temperature, such as in kitchens or laboratories.

Another benefit is its safety. As mentioned earlier, when broken, toughened glass fractures into small, harmless pieces, significantly decreasing the likelihood of injuries. This feature is particularly appealing for residential and commercial buildings where safety is a top priority.

The Science Behind Its Durability

The durability of toughened glass is primarily due to the microscopic stresses created during the tempering process. The consistent application of heat and the subsequent rapid cooling create a unique balance of tensions within the glass, allowing it to resist both physical impacts and thermal stress. Understanding these principles is crucial for engineers and designers, who must account for factors such as load, exposure to elements, and thermal expansion when selecting materials for construction or product design.

Conclusion

Toughened glass is an innovative material that combines craftsmanship and science to provide strength, safety, and versatility. Its manufacturing process, which includes heating and rapid cooling, transforms ordinary glass into a much more durable product capable of meeting the demands of modern life. As industries continue to evolve and seek greater safety and efficiency, the role of toughened glass will only grow, making it an invaluable component in construction, automotive, and everyday objects. As we advance technologically, the art of toughened glass making represents a perfect balance of innovation and necessity.

Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu