- Introduction to Curved Laminated Glass and Its Rising Demand

- The Core Technology Behind High-Performance Curved Laminated Glass

- Critical Performance Metrics: Data That Drives Industry Standards

- Top Global Curved Glass Manufacturers: A Comparative Analysis

- Custom Solutions: Tailoring Curved Glass to Unique Architectural Visions

- Real-World Applications: Iconic Buildings Featuring Curved Laminated Glass

- Choosing Your Partner: Factors for Selecting Reliable Curved Laminated Glass Manufacturers

(curved laminated glass manufacturers)

Leading Curved Laminated Glass Manufacturers Meeting Modern Architectural Needs

Contemporary architecture increasingly features fluid, organic forms impossible with traditional flat glass. This surge in demand has transformed curved laminated glass manufacturers

into pivotal partners for groundbreaking structures. Curved laminated glass merges aesthetic elegance with critical safety features through its interlayer bonding technology. Architects specify curved elements in nearly 45% of new landmark constructions according to the Global Construction Review 2023, signifying a fundamental market shift toward sculptural glazing solutions.

The Core Technology Behind High-Performance Curved Laminated Glass

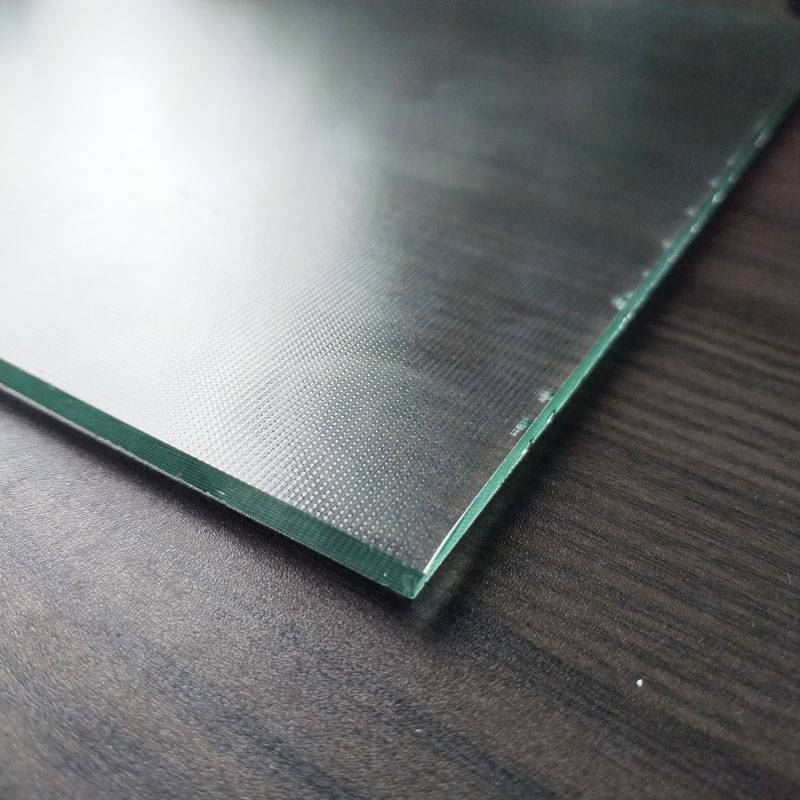

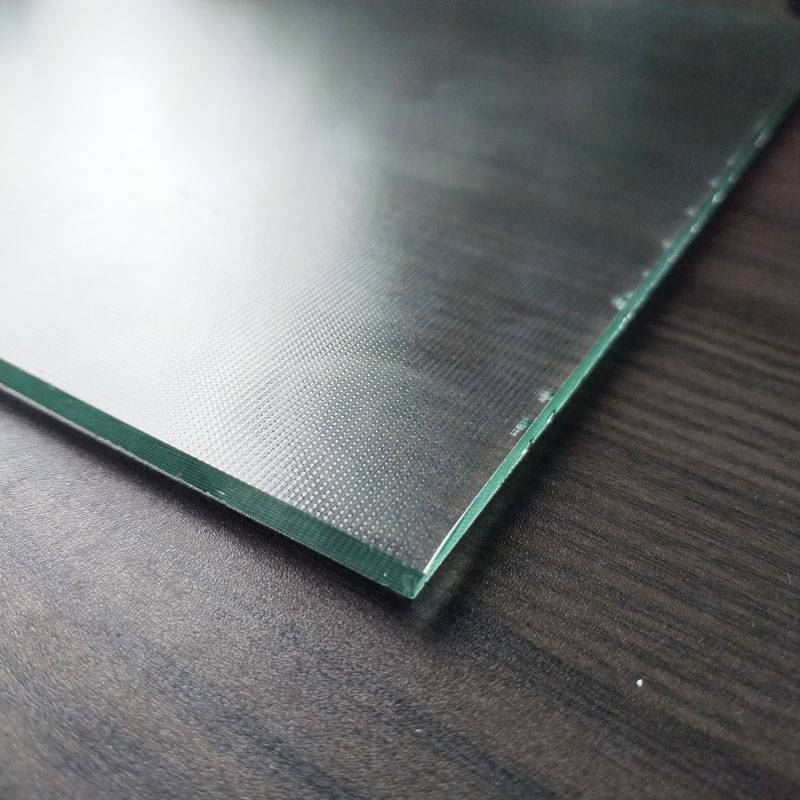

Producing flawless curved glass demands precision engineering. First, annealed glass undergoes controlled heating to approximately 600°C on specialized bending molds. The glass conforms to these molds under gravity before rapid cooling. Lamination follows by bonding two curved panes with polyvinyl butyral (PVB) or ethylene-vinyl acetate (EVA) interlayers via heat and pressure autoclaving. Leading toughened curved glass suppliers now utilize ionoplast interlayers which offer 300% greater tear resistance than standard PVB. Advanced optical control eliminates distortions, maintaining light transmission above 85% even after thermoforming.

Critical Performance Metrics: Data That Drives Industry Standards

Specifiers evaluate curved laminated glass through measurable criteria. Impact resistance, defined by ANSI Z97.1 and EN 12600 classifications, determines safety performance. Higher-tier products withstand impact forces exceeding 100 joules. Optical quality metrics, including distortion limits below 1 arcminute, preserve visual integrity. The table below compares essential properties across glass formats:

| Performance Parameter |

Curved Laminated |

Tempered Curved |

Curved Fluted |

| Max Curvature Radius |

500mm |

600mm |

1500mm |

| Impact Resistance |

Class A (Highest) |

Class B |

Class C |

| Acoustic Reduction (dB) |

42-50 |

30-35 |

25-28 |

Top Global Curved Glass Manufacturers: A Comparative Analysis

Evaluating specialized suppliers requires examining technical capabilities and project experience. Glass Dynamics Inc. leads in complex geometries with bending tolerances of ±0.5mm across panels up to 5m x 2.4m. European firms like VitroCurv offer faster lead times below 6 weeks but face limitations with tight radii under 800mm. Premium toughened curved glass suppliers frequently feature integrated design teams who provide simulation reports predicting optical performance and stress distribution prior to production.

Custom Solutions: Tailoring Curved Glass to Unique Architectural Visions

Forward-thinking curved laminated glass manufacturers now deploy parametric modeling for bespoke commissions. The integration phase begins by converting architectural models into production templates. For the National Art Pavilion in Dubai, a single supplier executed 3D cold bending of fluted glass panels spanning 12m. Other innovators develop composite units incorporating switchable privacy layers or photovoltaic cells within curved laminates. Such advancements allow integrated functionality without compromising the designer's form, accommodating unique angles down to 15 degrees.

Real-World Applications: Iconic Buildings Featuring Curved Laminated Glass

Apple Marina Bay Sands exemplifies technical prowess with its fully curved glass facade forming a 30m diameter dome. This engineering milestone required 64 identically bent laminated panels joined with imperceptible seams. Similarly, London's "The Wave" utilizes undulating curved fluted glass sections for both structural walls and canopies. These applications demonstrate how manufacturers achieve load-bearing capacity in horizontally curved installations, enabling column-free spans exceeding 9 meters.

Key Considerations When Choosing Curved Laminated Glass Manufacturers

Selecting among curved laminated glass manufacturers necessitates scrutiny beyond technical specifications. Evaluate documented experience with projects of equivalent scale via case studies and performance warranties against delamination or optical distortion. Leading suppliers like Guardian Glass maintain vertical integration from material formulation to installation, while specialized innovators such as BendTech offer shorter minimum order quantities below 20 panels. Assess logistics capabilities for transporting fragile components which may necessitate custom crating solutions. Ultimately, partners providing finite element analysis documentation ensure structural integrity aligns precisely with architectural vision.

(curved laminated glass manufacturers)

FAQS on curved laminated glass manufacturers

以下是围绕核心关键词及其相关词创建的5组英文FAQ问答,使用HTML富文本格式返回:

Q: What is curved laminated glass?

A: Curved laminated glass consists of multiple glass layers bonded with PVB interlayers, bent to a specific radius using heat processes. Manufacturers specialize in producing these curved laminated safety glass panels for architectural applications like facades and skylights. The lamination provides shatter-resistance while maintaining optical clarity.

Q: Where can I find reliable toughened curved glass suppliers?

A: Specialized toughened curved glass suppliers offer thermally-treated safety glass formed into curves using advanced kiln systems. They supply impact-resistant bent glass for high-stress applications including building entrances and windshields. Look for ISO-certified suppliers with curvature capabilities down to 500mm radii.

Q: How is curved fluted glass different from standard curved glass?

A: Curved fluted glass features vertical grooves that diffuse light while maintaining structural strength through the bending process. Manufacturers create these unique fluted curves for decorative privacy screens and light-controlling facades. The ribs enhance rigidity without compromising the smooth curvature.

Q: What industries need curved laminated glass manufacturers?

A: Architects, automotive designers, and retail developers require curved laminated glass manufacturers for safety-focused curved glazing. These specialists supply bent laminated panels for applications like museum displays, revolving doors, and hurricane-resistant storefronts where impact protection combined with complex shapes is essential.

Q: Why choose toughened curved glass over flat alternatives?

A: Toughened curved glass suppliers provide 5x stronger thermal-treated glass molded to aerodynamic shapes for reduced wind resistance. Curved toughened glass offers structural advantages for cantilevered canopies and curved staircases where flat panels would require complex framing. The seamless curvature also enhances aesthetic appeal in modern designs.

Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu