Float glass manufacturing stands as a pillar of modern architectural advancements, revolutionizing the way we perceive glass in both commercial and residential spaces. Rooted in the seamless marriage of technology and engineering, the float glass process offers exceptional clarity and uniformity essential for contemporary design demands. Here's an in-depth exploration of the float glass manufacturing process—an intricate blend of sophisticated science and operational precision.

At the heart of float glass production is a finely-tuned series of steps, each crucial in creating a flat,

flawless glass sheet. The journey begins with raw materials, primarily silica sand, soda ash, limestone, and other additives, chosen meticulously for purity. This mix is subjected to intense heat, reaching temperatures over 1500°C in a furnace where it transforms into molten glass.

This molten glass is then carefully directed onto a bed of molten tin, which provides a perfectly smooth surface due to its non-reactive nature and ideal density. The glass floats effortlessly, spreading out evenly, a method that ingeniously harnesses the fundamental principles of physics. This continuous sheet flows over the metal bath, its top side exposed to air, while the bottom is meticulously shaped by the tin.

Controlled cooling is pivotal as the glass makes its way from the tin bath to the annealing lehr. This gradual cooling process imbues the glass with critical resilience, mitigating internal stresses that might lead to imperfections or fractures. The precise control during this phase guarantees that the glass retains structural integrity, enhancing its durability for eventual use in various applications.

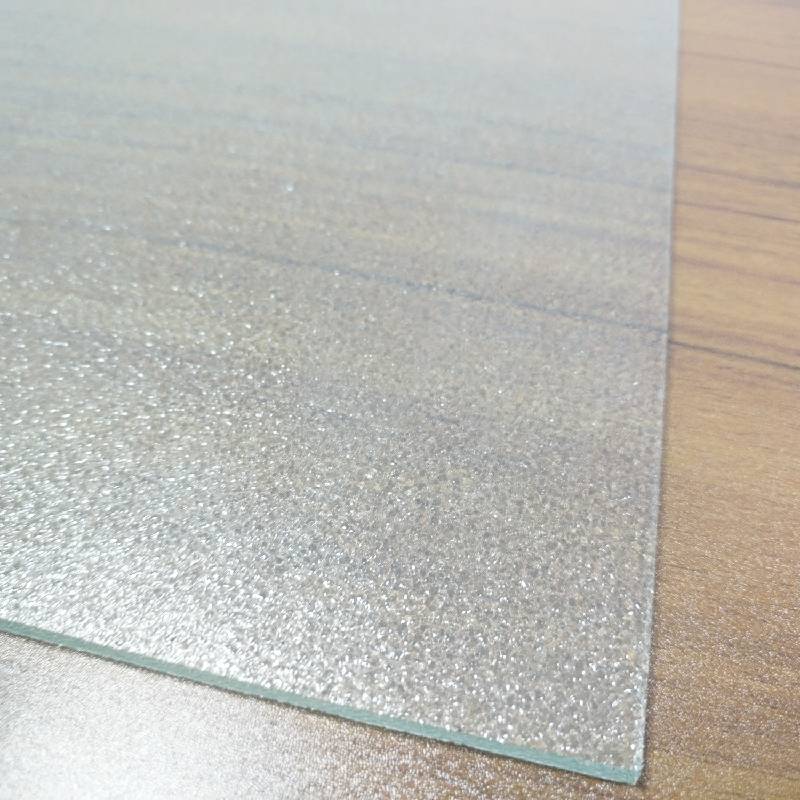

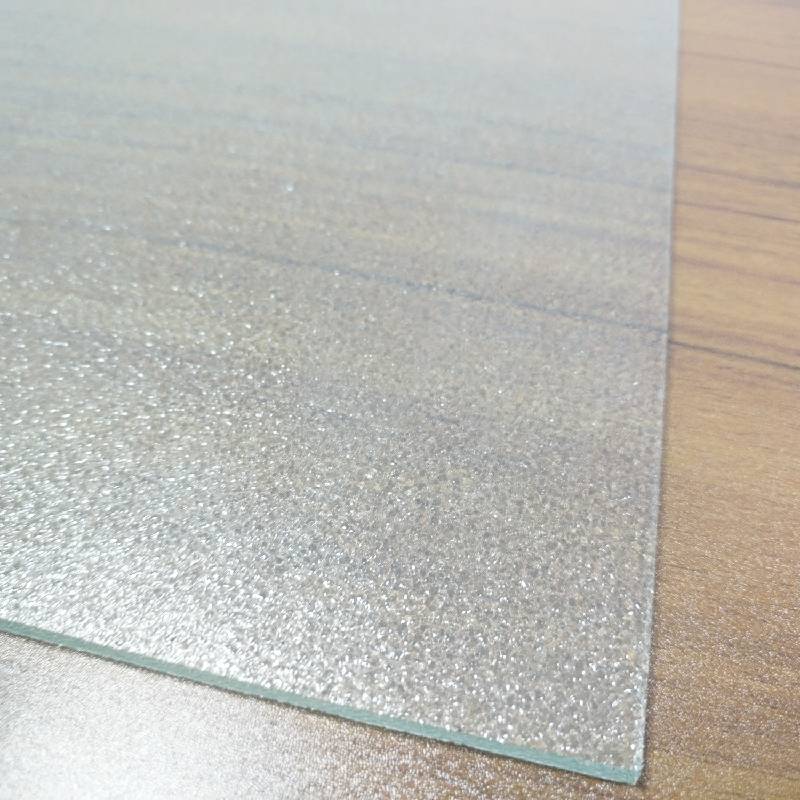

float glass manufacturing process

A testament to expertise, today's float glass manufacturing has evolved to include state-of-the-art technologies like automated inspection systems, which scrutinize every millimeter of the glass for defects. These systems ensure that each pane meets stringent quality standards, a crucial aspect for industries where precision and reliability define success.

Environmentally, the float glass process is continuously refined to reduce its carbon footprint, integrating sustainable practices such as recycling waste glass during production. The use of advanced furnaces further reflects a commitment to energy efficiency, underscoring the industry's effort to minimize environmental impact.

Expertise in float glass production is further exemplified by the consistent innovation seen in product offerings—from energy-efficient low-emissivity glass to specialized coatings enhancing capabilities like thermal insulation and UV protection. Such advancements not only affirm the industry's authority but also build trust with consumers seeking superior and sustainable glass solutions.

Through experience and cutting-edge developments, the float glass manufacturing process stands as a bastion of modern engineering, embodying reliability, precision, and innovation. Its products, known for their elegance and practicality, continue to inspire architectural grandeur around the globe, reflecting the expertise and trustworthiness synonymous with this essential material.

Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu