Float Glass Production An Overview of the Process and Its Importance

Float glass is one of the most widely used types of glass in the world, known for its clarity and uniform thickness. The float glass production process is a significant advancement in glass manufacturing, allowing for the creation of sheets of glass that meet stringent quality standards. This article explores the float glass production process, its importance, and its applications.

The Float Glass Process

The float glass manufacturing process was developed in the 1950s and has since revolutionized the glass industry. The core of this method involves melting raw materials, which primarily include silica sand, soda ash, and limestone, in a furnace at temperatures exceeding 1,600 degrees Celsius. Once the batch is melted, it is transformed into molten glass.

The key innovation in float glass production is the technique of floating the molten glass on a pool of molten tin. When the molten glass is poured onto the molten tin, it spreads out and forms a flat sheet. The surface tension between the two liquids ensures that the glass achieves a perfectly smooth and uniformly thick surface. The thickness of the glass can be controlled by adjusting the amount of molten glass poured onto the tin bath.

After the glass has formed, it is allowed to cool gradually in a controlled environment. This annealing process helps to relieve internal stresses and solidifies the glass, ensuring that it maintains its integrity and clarity. The cooled glass can then be cut into sheets of various sizes, depending on its intended application.

Importance of Float Glass

Float glass is integral to numerous industries because of its versatility, optical clarity, and durability. It is primarily used in the construction industry for windows, facades, and skylights, providing natural light while delivering energy efficiency. Its smooth surface and clarity make it an ideal choice for architectural applications, enhancing both aesthetics and functionality.

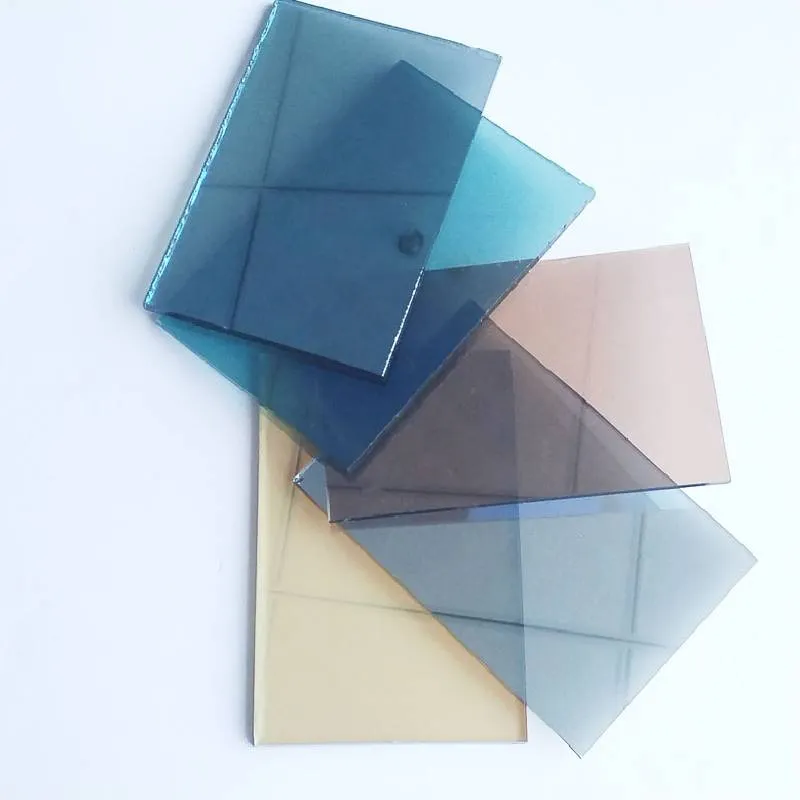

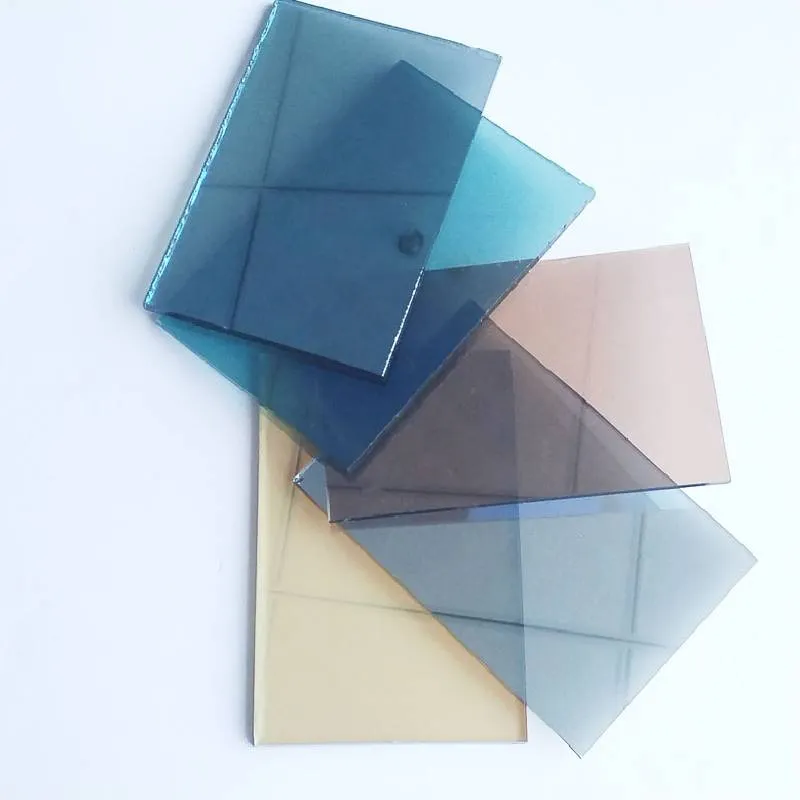

float glass production

Additionally, float glass is crucial in the automotive industry. Windshields, side windows, and rear windows are typically made from float glass due to its ability to provide safety and visibility. The glass can also be treated or laminated to offer additional protection against shattering, increasing passenger safety.

Beyond construction and automotive applications, float glass is extensively used in the manufacturing of household items, such as mirrors, table tops, and glass doors. It also plays an essential role in the electronics industry, where screens for televisions, computers, and mobile devices are made using high-quality float glass.

Sustainability in Float Glass Production

In recent years, sustainability has become a vital focus in float glass production. Manufacturers are exploring ways to minimize energy consumption and reduce emissions during the melting process. Many companies now use cullet, or recycled glass, in their production, which not only lowers energy requirements but also reduces waste.

The use of energy-efficient furnaces and the incorporation of renewable energy sources are also making float glass production more sustainable. As the demand for eco-friendly products increases, the glass industry continues to adapt and innovate.

Conclusion

Float glass production is a remarkable process that provides high-quality glass for various applications across multiple industries. Its impact on construction, automotive, and everyday products reflects its significance in modern society. As sustainability initiatives take center stage, the float glass industry is poised to evolve, ensuring that it meets the needs of a growing global population while minimizing its environmental footprint. The future of float glass production looks bright, with advancements in technology and a commitment to sustainable practices driving it forward.

Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu