This comprehensive guide covers crucial aspects of specialized glass pricing and selection. The key discussion points include:

- Critical price determinants for tempered glass

- Technical advantages compared to standard glass

- Manufacturer comparisons across product categories

- Customization variables and cost implications

- Real-world application case studies

- Future pricing trends and analysis

- Smart purchasing strategies for buyers

(hardened glass price)

Critical Factors Affecting Hardened Glass Pricing

Understanding tempered glass price variations begins with analyzing composition variables. Standard thickness options range from 3mm to 19mm, with price fluctuations of 15-20% between size brackets. Custom dimensions exceeding standard fabrication sizes incur 30-50% premiums. Surface modifications like digital printing add $25-$80 per square meter, while ceramic frit applications increase costs by $35-$100 per square meter. International material sourcing factors create regional disparities: North American manufactured glass averages 5-8% higher than Asian imports. Shipping contributes 12-18% to total installed costs, particularly impacting oversized panels exceeding standard container dimensions.

Technical Superiority of Safety Glass Solutions

Thermal tempering enhances structural performance exponentially. Heat-treated panels demonstrate 4-5x greater impact resistance than annealed alternatives, capable of withstanding pressures exceeding 24,000 PSI. Thermal shock resistance thresholds reach 200°C compared to standard glass's 70°C limitation. Fracture analysis reveals tempered glass shatters into granular fragments reducing injury potential to under 3% of conventional glass accidents. Factory quality assurance requires precise temperature controls within ±2°C and specialized quenching chambers creating surface compression forces of 10,000-12,000 PSI. Certifications like ANSI Z97.1 and EN 12150 validate impact resistance through standardized testing methodologies using shot bags weighing 100±2 pounds.

Manufacturer Comparison and Cost Analysis

Significant price differentiation exists across leading safety glass manufacturers:

| Manufacturer |

Standard 6mm Panel ($/m²) |

10mm Laminated ($/m²) |

Bending Premium (%) |

Minimum Order (m²) |

Lead Time (Weeks) |

| Guardian Glass |

$84.50 |

$137.90 |

55-60% |

500 |

6-8 |

| Saint-Gobain |

$92.75 |

$151.25 |

70-75% |

750 |

8-10 |

| Asahi Glass |

$78.40 |

$127.85 |

50-55% |

350 |

5-7 |

| Regional Suppliers |

$68.90 |

$118.30 |

85-90% |

100 |

3-4 |

Specialist producers like Bent Glass Design achieve precision bending with <0.5mm tolerance but command 85-110% premiums. Lead times inversely correlate with order quantity, decreasing by 40% for contracts exceeding 5,000 square meters.

Customization Variables Impacting Tempered Glass Price per Square Meter

Architectural specifications exponentially influence project quotations. Geometric complexity adds 25-150% to base costs depending on cutting precision requirements. Minimal edgework modifications like seamed edges incur $4-$8/m premium while comprehensive CNC machining with mitred joints increases costs by $28-$55/m². Hole cutting initiates at $15 per penetration while decorative sandblasting ranges from $40 to $125/m² depending on pattern complexity. Solar performance coatings alter pricing by $85-$210/m² for spectrally selective options. Installation environment factors compound costs: structural glass fins require 0.5% additional material thickness per vertical meter exceeding three stories.

Implementation Case Studies and Project Analysis

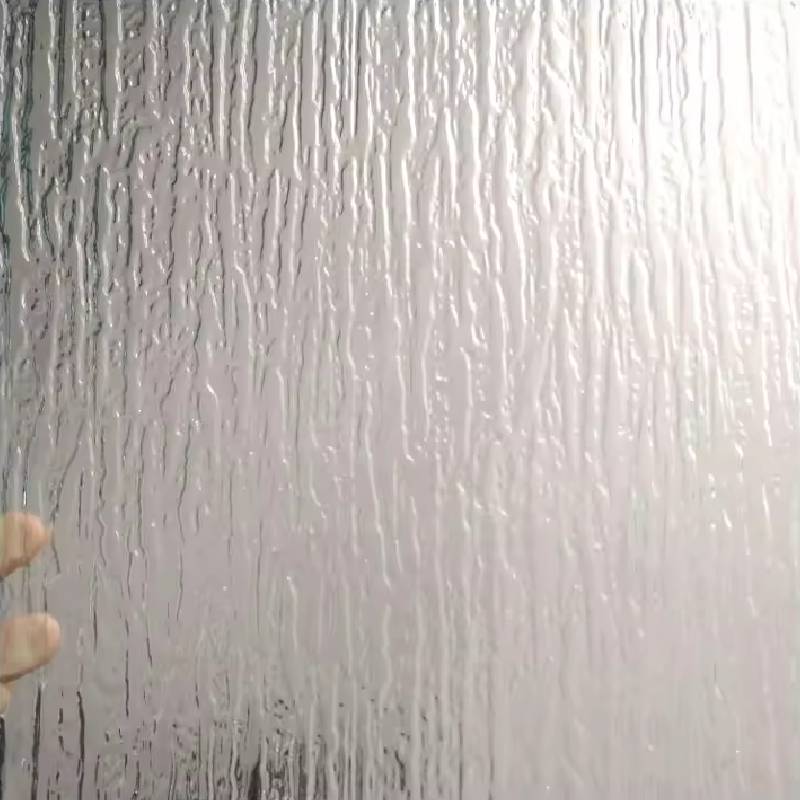

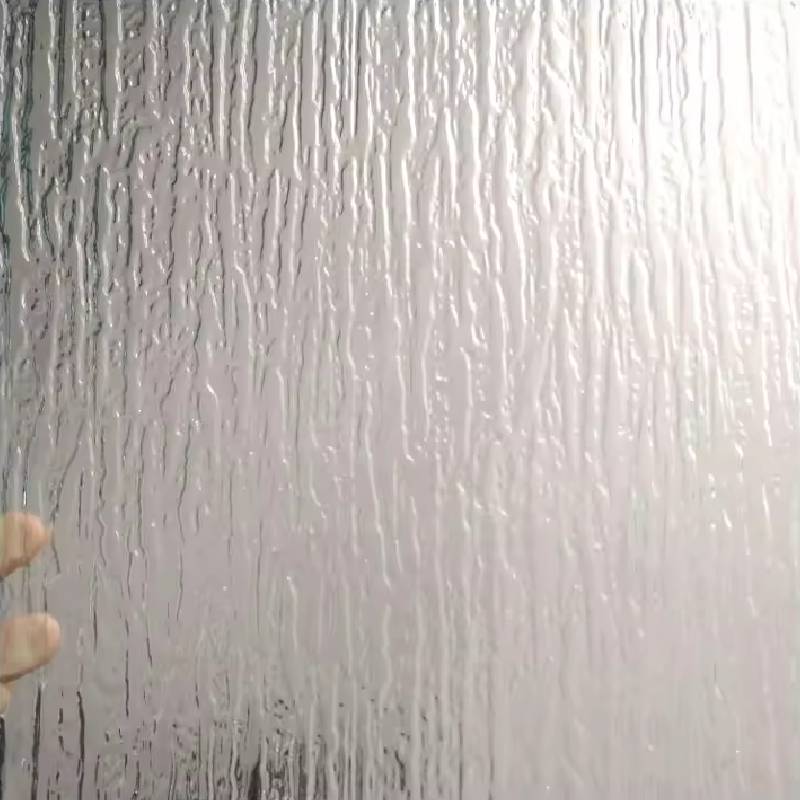

The Hudson Yards glass atrium installation demonstrates structural applications: 6,500m² of 15mm heat-soaked tempered glass supporting 30-ton roof systems, achieving price optimization through volume procurement at $195/m² installed. Commercial shower enclosure contracts illustrate bathroom solutions: 8mm clear tempered installations at $145/m² including custom hardware, achieving 97% reduction in maintenance costs compared to acrylic alternatives. High-security applications at JP Morgan Chase headquarters implemented multi-laminated systems: three layers of 8mm glass with 1.52mm PVB interlayers achieving Level 3 bullet resistance at $680/m² installed. Environmental testing showed 98% UV blocking efficiency after three-year exposure cycles.

Pricing Trends and Market Forecasting

Float glass commodity pricing fluctuations directly impact future costs. Historical data indicates 5-7% annual escalation before the energy crisis; current projections suggest 9-11% through 2026. Natural gas prices account for 35% of manufacturing costs, resulting in European production expenses increasing by 22% during 2022-2023. Tariff structures influence global pricing: Section 301 duties increased Chinese import costs by 28.5% while ASEAN-sourced alternatives carry only 4-7% tariffs. Automation breakthroughs including Industry 4.0 fabrication processes show potential for 18-25% production cost reduction within five years. Commercial construction demand predicts 6.2% CAGR through 2030, maintaining upward pressure on prices.

Strategic Acquisition Approaches for Tempered Glass Wall Price Optimization

Procurement efficiency significantly impacts total expenditure. Volume discounts typically activate at 500m² increments with thresholds at 5% reduction (500-1,000m²), 11% reduction (1,001-2,500m²) and maximum 18% discount beyond 5,000m². Off-season purchasing during construction downturns secures additional 8-12% savings. Payment term negotiations provide substantial leverage: 5/10 net 30 arrangements effectively reduce costs by 3.5-4.2%. When evaluating hardened glass price

structures, specification adjustments yield savings: 15mm thickness instead of 19mm provides 23% material reduction with identical safety certification compliance. Third-party testing verification prevents over-engineering costs by ensuring precise specification compliance rather than blanket upgrades. Lifecycle costing reveals optimal expenditure: premium low-iron glass generates 80% greater residual value than conventional options after fifteen years of service.

(hardened glass price)

FAQS on hardened glass price

Q: What affects the hardened glass price?

A: The hardened glass price is influenced by factors like thickness, size, and customization requirements. Material quality and brand reputation also impact costs. Generally, thicker pieces or specialized designs are more expensive.

Q: How much does tempered glass cost per square meter?

A: The tempered glass price per square meter ranges from $20 to $60 on average. Variations depend on thickness, coatings, and supplier pricing. Complex finishes or safety features can increase costs further.

Q: What determines the tempered glass wall price?

A: The tempered glass wall price factors in materials, labor, and installation complexity. Wall dimensions and reinforcement needs contribute to the overall expense. Custom designs or high-end finishes often add to the base price.

Q: Is tempered glass wall price higher than regular glass?

A: Yes, tempered glass wall price is typically 20-50% higher due to enhanced safety and durability. The tempering process increases production costs. Installation requirements for walls also add to the total expense.

Q: What is the price range for hardened glass in walls?

A: Hardened glass price for walls starts from $30 to $100 per square meter. Thickness, such as 6mm or 10mm, plays a key role in pricing. Additional factors include quantity discounts and regional market trends.

Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu