Understanding Heat-TEMPERED GLASS Benefits, Applications, and Manufacturing

Heat-tempered glass, also known as toughened glass, is a remarkable material that has revolutionized various industries due to its enhanced strength and safety features. This specialized type of glass undergoes a rigorous manufacturing process that involves heating and rapid cooling, which significantly improves its durability and resistance to thermal stress. In this article, we will explore the benefits, applications, and manufacturing process of heat-tempered glass.

Benefits of Heat-Tempered Glass

1. Increased Strength One of the primary advantages of heat-tempered glass is its increased strength compared to standard glass. The tempering process creates compressive stress on the surface of the glass, thereby enhancing its resistance to impact and pressure. This makes heat-tempered glass an ideal choice for environments where safety is a priority.

2. Safety In the event that heat-tempered glass breaks, it shatters into small, blunt pieces rather than sharp shards. This characteristic significantly reduces the risk of injury, making it suitable for applications in public spaces, homes, and vehicles. Safety is a crucial consideration in sectors like architecture and automotive manufacturing, where tempered glass is commonly used.

3. Thermal Resistance Heat-tempered glass can withstand high temperatures and sudden temperature changes without breaking. This attribute is particularly valuable in applications where the glass is exposed to extreme heat, such as in shower doors, oven doors, and where sunlight intensity fluctuates, allowing for the incorporation of large glass surfaces in buildings.

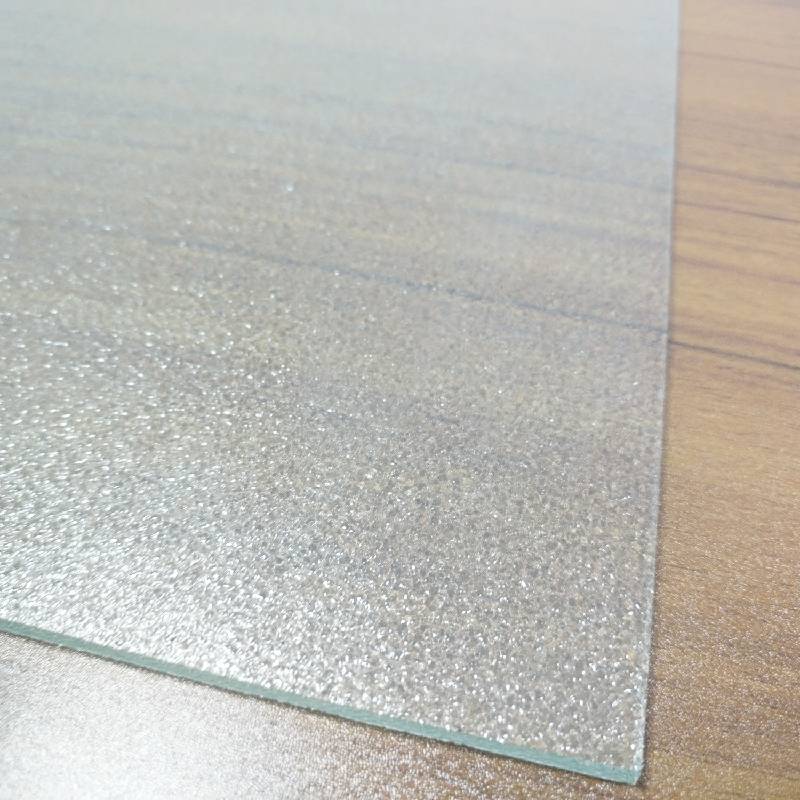

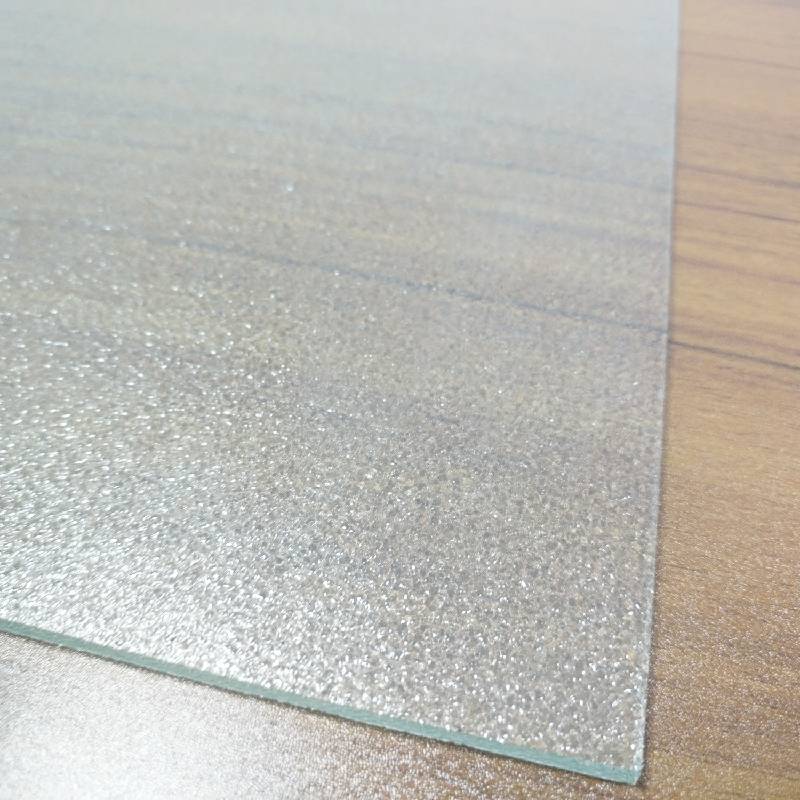

4. Aesthetic Appeal In addition to its safety and strength benefits, heat-tempered glass is available in various designs and can be treated with coatings to enhance its appearance. The transparency and clarity of tempered glass provide a modern and elegant look, contributing significantly to contemporary architecture and interior design.

Applications of Heat-Tempered Glass

The versatility of heat-tempered glass means it finds use in a wide range of applications

- Architecture and Construction In commercial and residential buildings, tempered glass is often used for windows, facades, and glass doors. Its strength allows for large panels of glass to be used without the need for heavy framing, promoting an open and airy feel in spaces.

- Automotive Industry Heat-tempered glass is standard in car windows, windshields, and sunroofs. The glass’s ability to withstand impacts and prevent shattering ensures passenger safety, making it a vital element of modern vehicle design.

heat tempered glass

- Furniture Glass tables and shelves utilize heat-tempered glass to ensure durability and safety

. The combination of aesthetic appeal and strength makes it a popular material in furniture design.

- Shower Enclosures The use of tempered glass in bathroom shower enclosures not only enhances the safety of users but also adds a sleek and modern touch to bathroom interiors.

- Public Spaces The use of heat-tempered glass in public places, such as airports, shopping malls, and schools, showcases its strength and safety properties, making it a preferred choice for architects and builders.

Manufacturing Process

The manufacturing of heat-tempered glass involves several critical steps

1. Cutting Large sheets of glass are cut to the desired size before the tempering process begins.

2. Heating The glass is then heated to temperatures up to 620 degrees Celsius (about 1,148 degrees Fahrenheit) in a controlled oven. This process is crucial for creating the internal stresses that will give the glass its strength.

3. Cooling After reaching the desired temperature, the glass is rapidly cooled through a process called quenching. This sudden temperature drop creates compressive forces on the surface, enhancing the glass’s strength and thermal stability.

4. Finishing Finally, the tempered glass may go through additional finishing processes, such as polishing or coating, to meet specific aesthetic or functional requirements.

Conclusion

Heat-tempered glass is an exceptional material that combines strength, safety, and aesthetic appeal, making it a preferred choice across various industries. From architecture to automotive applications, heat-tempered glass continues to prove its versatility and reliability. As technology advances, we can expect even more innovative applications for this remarkable material in the future, enhancing safety and design in our daily lives.

Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu