The Clear Glass Factory A Journey Through Transparency and Innovation

In a world increasingly dominated by mass production and synthetic materials, the clear glass factory stands out as a testament to craftsmanship, innovation, and sustainability. This facility specializes in the production of clear glass products, ranging from everyday items like bottles and windows to intricate decorative pieces and industrial components. The enchanting process of transforming raw materials into transparent creations is not only a marvel of engineering but also a reflection of our relationship with nature and resources.

At the heart of every clear glass factory lies the fundamental ingredient silica sand

. This pure, fine sand, along with other components such as soda ash and limestone, forms the basis of most glass products. The journey begins in the factory's extensive raw material section, where miners and suppliers work diligently to ensure high-quality materials are available for production. Environmental sustainability is a critical focus, as many factories have implemented measures to source materials responsibly and minimize their ecological impact.

Once the raw materials are gathered, the glassmaking process truly begins. The first step involves melting the ingredients in a furnace that operates at extraordinarily high temperatures, often exceeding 1,700 degrees Celsius. This intense heat liquefies the materials into a viscous liquid known as molten glass. The clarity and purity of the glass are paramount, as any impurities can compromise the final product. Skilled technicians monitor the melting process closely, adjusting the temperature and composition as necessary to achieve the desired transparency and quality.

As the molten glass is prepared, it moves to the forming stage, where it takes on its final shape. The versatility of glass is evident in this phase, as various methods such as blowing, molding, and pressing are employed. For instance, skilled artisans use traditional glassblowing techniques to create unique, handcrafted pieces, infusing each item with individuality. In contrast, modern machinery allows for high-speed production of standardized products, catering to the demands of a fast-paced market. This blend of artistry and technology exemplifies the factory's commitment to both innovation and tradition.

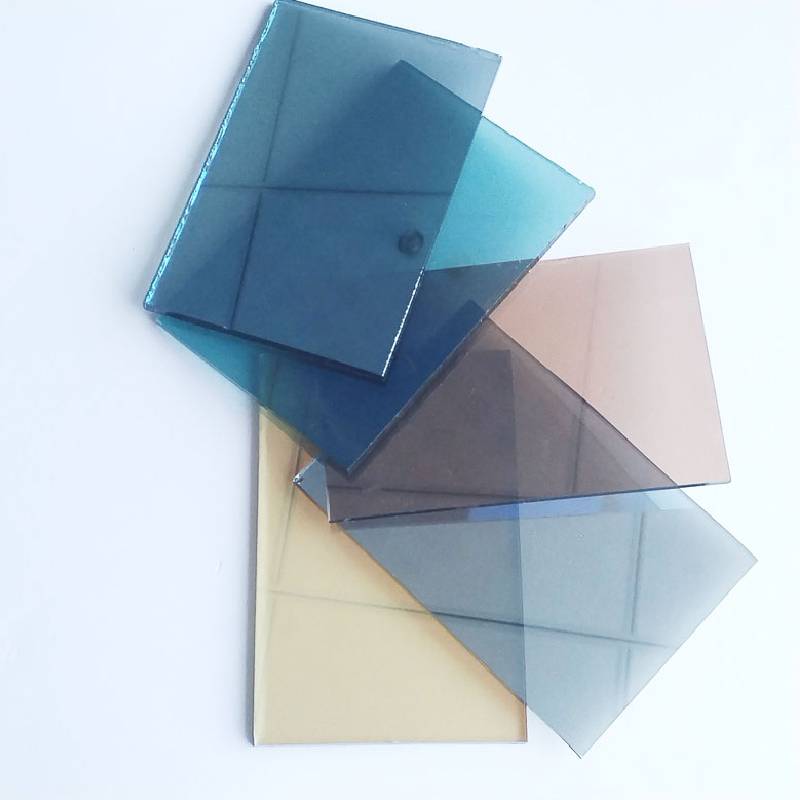

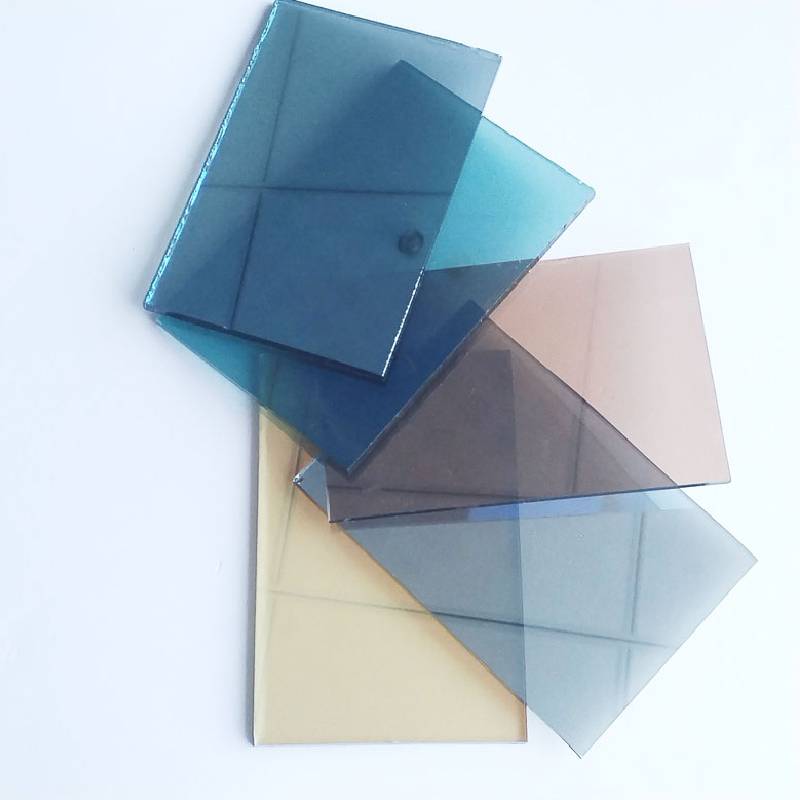

clear glass factory

Once shaped, the glass products undergo a rigorous annealing process. This crucial step involves slowly cooling the glass in a controlled environment, reducing internal stresses and enhancing durability. Quality control is another vital aspect of the factory's operations. Each item is meticulously inspected for defects such as bubbles, cracks, or inconsistencies. Only the most flawless pieces are deemed fit for sale, ensuring customers receive nothing less than the highest quality products.

In recent years, clear glass factories have also embraced sustainable practices. Many have adopted recycling programs, where waste materials are reprocessed into new glass products. This initiative not only conserves resources but also reduces energy consumption compared to producing glass from raw materials. Moreover, advancements in technology have led to the development of energy-efficient furnaces and production methods, minimizing the environmental footprint of glass manufacturing.

The clear glass factory is more than just a place of production; it is a hub of innovation and sustainability. By marrying traditional techniques with modern technology, these factories continue to evolve, shaping our understanding of materials and design. As consumers become increasingly conscious of their choices, the demand for sustainable glass products is set to rise, prompting factories to reassess their practices and embrace a greener future.

In conclusion, the clear glass factory symbolizes a delicate balance between craftsmanship and innovation. From the careful selection of raw materials to the skilled artistry of glassblowing and the implementation of sustainable practices, each facet of production contributes to a beautiful and functional final product. As we look towards a future where transparency and sustainability are paramount, the clear glass factory will undoubtedly play a significant role in shaping our world.

Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu