In the vast landscape of materials engineered for optical precision and aesthetic appeal, the aluminum mirror stands as a testament to innovative manufacturing and versatile application. From the subtle glint in interior décor to its critical role in advanced scientific instruments, the evolution of aluminum mirror technology reflects a continuous pursuit of performance, efficiency, and sustainability. This comprehensive guide delves into the world of aluminum mirrors, exploring their intricate manufacturing processes, diverse applications, inherent advantages, and what sets leading manufacturers apart.

1. The Resurgence of Aluminum Mirror Technology: Industry Trends and Innovations

The global mirror market, a significant segment of which is occupied by the aluminum mirror, is experiencing robust growth, driven by increasing demand across various sectors. According to recent market reports, the optical mirror market, including various types of metallic mirrors, is projected to grow at a compound annual growth rate (CAGR) of approximately 6-7% from 2023 to 2028, reaching an estimated value of over $5 billion. This surge is largely attributable to advancements in manufacturing technologies, leading to more cost-effective and higher-performance products, as well as an expanding array of applications.

Historically, mirrors were primarily made with silver, known for its high reflectivity. However, silver is prone to tarnishing and corrosion, especially in humid or chemically active environments. The advent of the aluminum mirror, particularly through vacuum deposition techniques, offered a durable and cost-effective alternative. Modern trends highlight a shift towards sustainable manufacturing practices, with a focus on reducing energy consumption and waste during production. Furthermore, the demand for specialized coatings, such as protective layers for enhanced durability or specific wavelength reflection, is on the rise. Innovations in this field are also exploring smart mirror technologies incorporating touchscreens and IoT capabilities, expanding the utility of what was once a purely reflective surface.

Emerging applications include the integration of black aluminum mirror variants for unique aesthetic effects in high-end design, and advanced applications in solar energy for concentrating photovoltaic (CPV) systems. The shift towards lightweight and durable materials in automotive and aerospace industries also positions the aluminum mirror as a preferred choice. Manufacturers are now capable of producing large-format mirrors with exceptional flatness and minimal distortion, catering to architectural and large-scale solar projects. This continuous innovation ensures that the aluminum mirror remains at the forefront of optical material technology.

2. Deconstructing the Aluminum Mirror: Technical Parameters and Performance Metrics

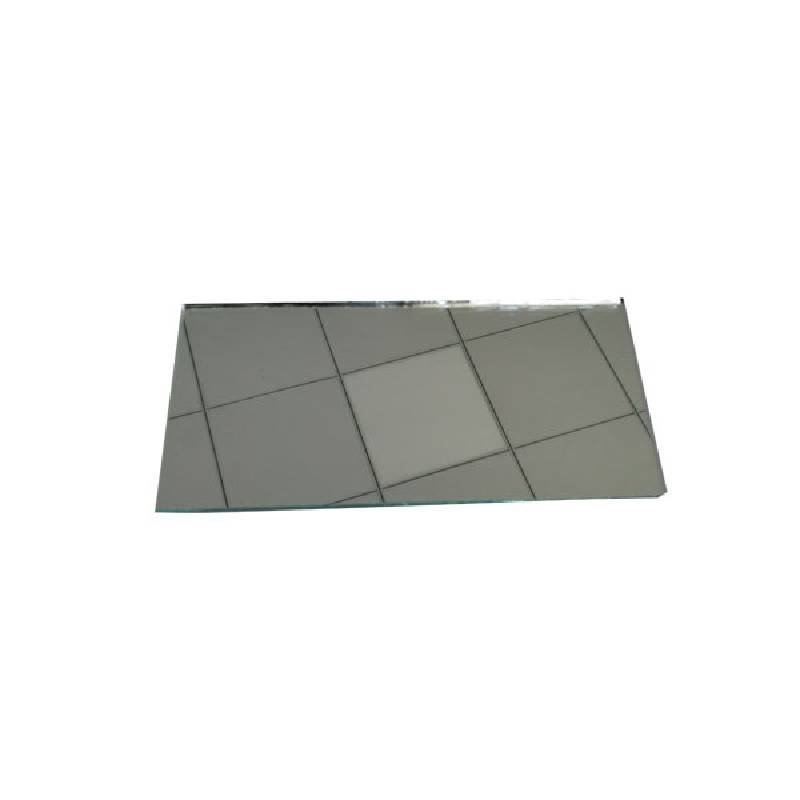

An aluminum mirror typically consists of a glass substrate coated with a thin layer of aluminum, followed by one or more protective layers. The selection of the glass substrate (e.g., float glass, ultra-clear glass) plays a crucial role in determining the overall optical quality and flatness of the finished product. The aluminum layer, usually applied through a vacuum metallization process, is responsible for the reflective properties. Finally, protective coatings, often made of silicon monoxide or titanium dioxide, are applied to prevent oxidation, scratches, and chemical degradation, extending the mirror's lifespan and maintaining its optical performance.

Key technical parameters that define the quality and performance of an aluminium mirror glass include:

- Reflectivity: Typically ranges from 85% to 92% for visible light, though specialized coatings can achieve higher or tailored reflectivity across different spectrums. Standard aluminum mirrors offer good broad-spectrum reflectivity, making them suitable for general applications.

- Substrate Thickness: Common thicknesses range from 2mm to 6mm, but can be customized based on application requirements for rigidity and weight.

- Optical Flatness: Crucial for precision applications, measured in wavelengths (e.g., lambda/4, lambda/10). High-quality mirrors exhibit minimal distortion.

- Durability: Resistance to abrasion, chemicals, and environmental factors (humidity, temperature fluctuations). This is largely determined by the quality and type of protective layers.

- Operating Temperature Range: Standard mirrors perform well within typical indoor temperatures, but special formulations can withstand extreme conditions for industrial or outdoor use.

- Corrosion Resistance: Especially important in humid or industrial environments where ordinary mirrors might degrade quickly. The protective layers on aluminum mirrors offer enhanced resistance compared to unprotected metallic surfaces.

Table 1: Common Technical Specifications for Aluminum Mirrors

| Parameter |

Typical Range/Value |

Remarks |

| Reflectivity (Visible Light) |

85% - 92% |

Higher reflectivity achievable with specific coatings. |

| Thickness |

2mm, 3mm, 4mm, 5mm, 6mm |

Customizable based on structural needs. |

| Max Size (Standard) |

3660mm x 2440mm |

Larger sizes available from specialized aluminum mirror manufacturers. |

| Resistance to Oxidation |

Excellent |

Due to protective layers, superior to silver mirrors. |

| Acid/Alkali Resistance |

Good |

Dependent on protective coating type and thickness. |

| Weight (4mm thick) |

~10 kg/m² |

Lightweight compared to other materials for similar applications. |

| Operating Temperature |

-20°C to +80°C |

Special versions for wider ranges. |

These specifications are critical for engineers and designers when selecting the appropriate aluminum mirror for their specific application, ensuring optimal performance and longevity.

3. Manufacturing Excellence: The Art and Science Behind Aluminum Mirror Production

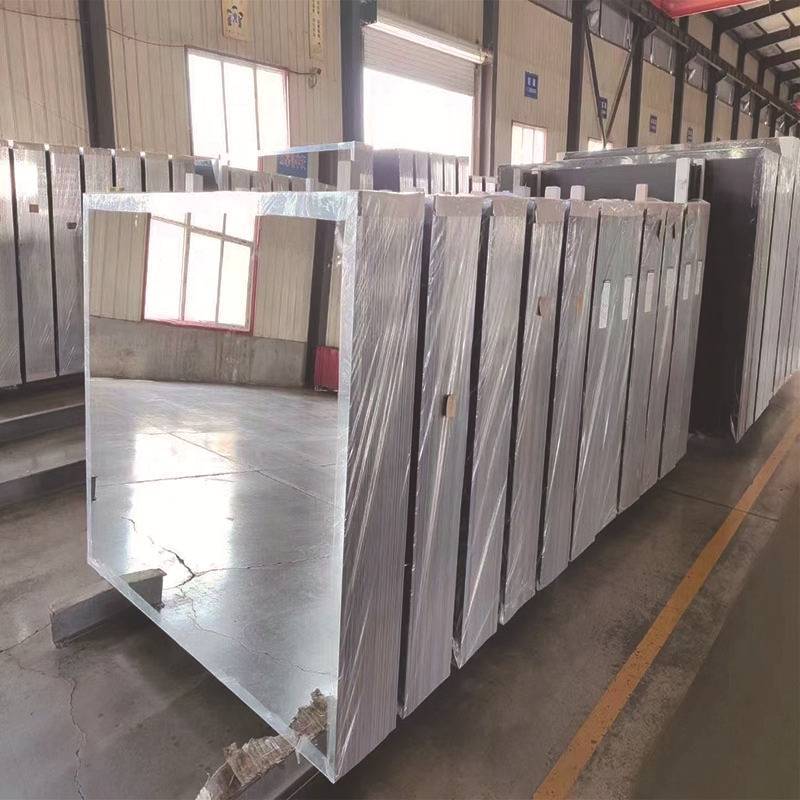

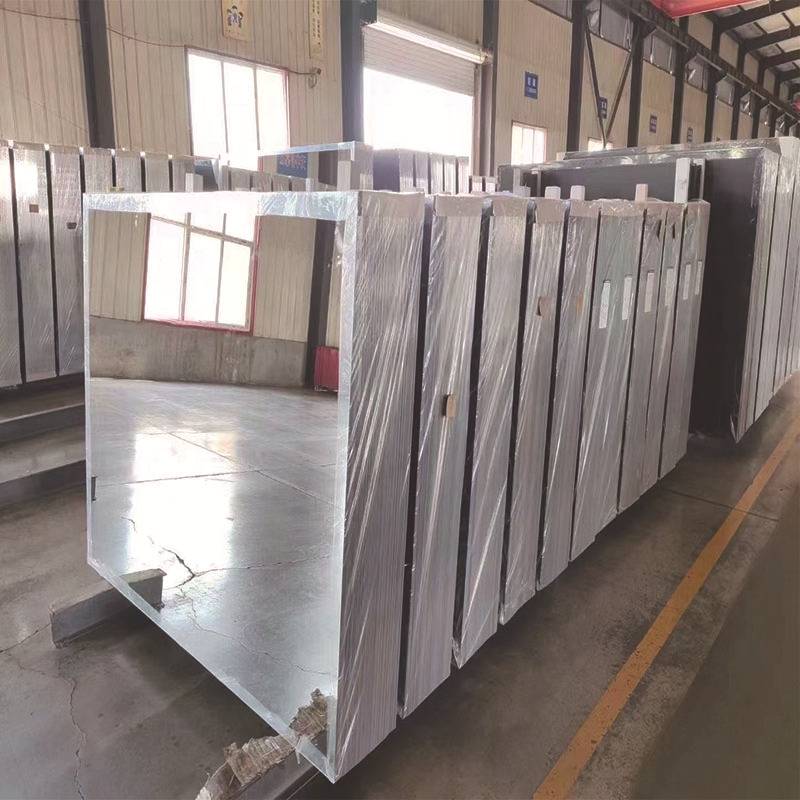

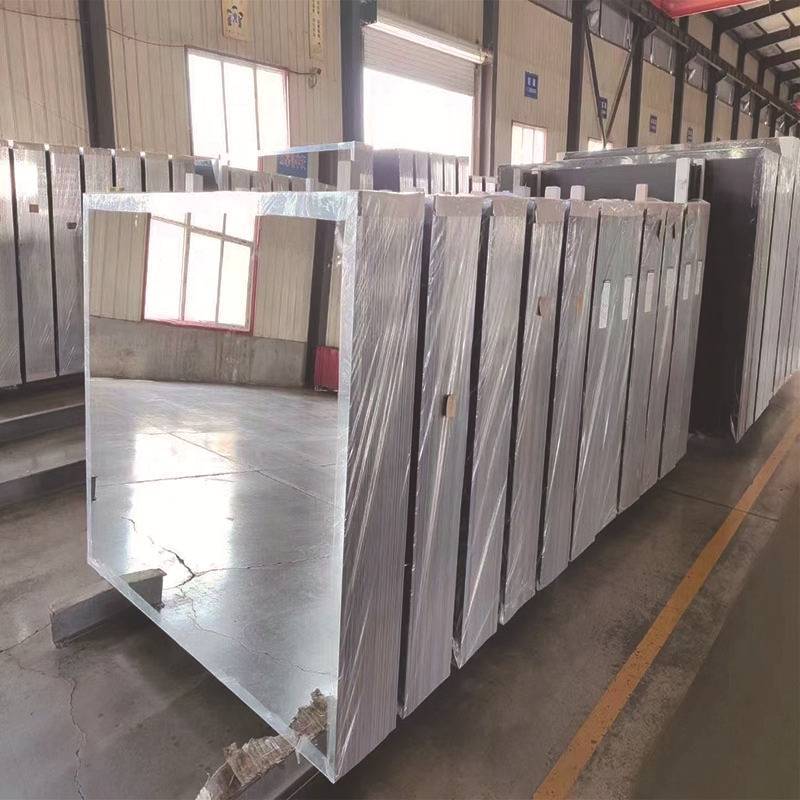

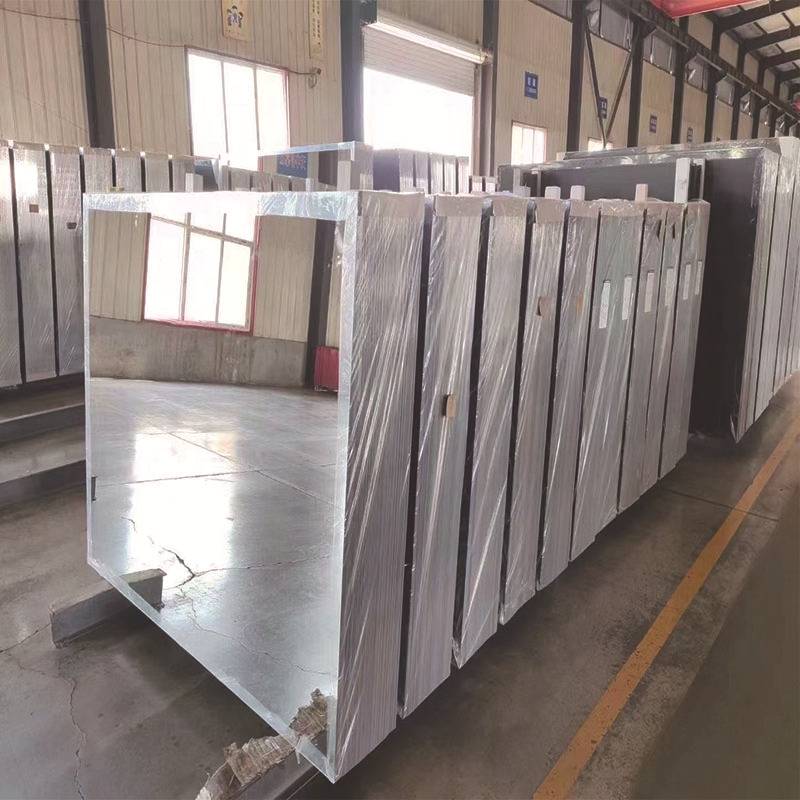

The manufacturing of a high-quality aluminum mirror is a sophisticated process that combines precision engineering with advanced material science. It typically involves several critical stages, each contributing to the final product's optical and physical properties. The process is often carried out in cleanroom environments to prevent contamination and ensure flawless surfaces.

Detailed Process Flow:

- Glass Substrate Preparation:

- Cutting: High-quality float glass or ultra-clear glass is cut to the desired dimensions using automated glass cutting machines, which can include CNC (Computer Numerical Control) processing for intricate shapes and precise tolerances.

- Edging & Grinding: Edges are precisely ground and polished to remove sharp corners and improve safety and aesthetics. This step is crucial for architectural and decorative applications.

- Washing & Cleaning: The glass surface undergoes multiple stages of thorough cleaning using deionized water, specialized detergents, and brushes, followed by high-pressure rinsing and drying. This removes all dust, oils, and contaminants, which are detrimental to adhesion and optical quality. A perfectly clean surface is paramount for optimal adhesion of the aluminum layer and subsequent coatings.

- Vacuum Metallization (PVD - Physical Vapor Deposition):

- Loading: Cleaned glass panels are loaded into a large vacuum chamber.

- Vacuum Evacuation: The chamber is evacuated to a high vacuum level (typically 10^-5 to 10^-6 Torr). This low-pressure environment is essential to prevent atmospheric gases from interfering with the deposition process and to ensure a pure aluminum film.

- Aluminum Evaporation: Aluminum pellets or wire are heated to their evaporation point (over 1000°C) in a crucible or through electron beam evaporation. The aluminum vapor then travels through the vacuum and condenses onto the cooler glass surface, forming a uniform, thin metallic layer. The thickness of this layer is precisely controlled to achieve optimal reflectivity.

- Protective Layer Application:

- First Protective Layer (e.g., Silicon Monoxide - SiO): Immediately after the aluminum deposition and often within the same vacuum chamber (in-situ), a protective layer, such as silicon monoxide (SiO) or silicon dioxide (SiO2), is applied. This layer significantly enhances the mirror's resistance to oxidation and environmental degradation. This is a critical step, as aluminum itself is highly reactive with oxygen.

- Second Protective Layer (e.g., Titanium Dioxide - TiO2 or Epoxy Paint): For enhanced durability, especially for mirrors exposed to harsh environments (like bathrooms or outdoor use), an additional protective coating is applied. This can be another vacuum-deposited layer or a robust paint coating (e.g., epoxy or lead-free paint) applied via roller coating or spraying, and then cured. This layer provides resistance against scratches, moisture, and common household chemicals, greatly increasing the mirror's service life.

- Curing and Inspection:

- Curing: If paint coatings are used, they are typically cured in an oven at specific temperatures to ensure full cross-linking and hardness.

- Quality Control and Inspection: Throughout the process, and especially at the final stage, rigorous quality control measures are implemented. This includes visual inspection for defects, measurement of reflectivity using spectrophotometers, adhesion tests (e.g., cross-cut test), and environmental resistance tests (e.g., salt spray test, humidity test). Compliance with international standards such as ISO 9001 for quality management systems and specific product standards like ANSI Z97.1 for safety glazing materials or EN 1036 for glass in building is strictly adhered to.

This meticulous process ensures that the finished aluminum mirror not only possesses excellent reflective properties but also exhibits superior durability and a long service life, making it suitable for a wide range of demanding applications across industries like petrochemical, metallurgy, and water supply/drainage, where its anti-corrosion and stable reflective properties are highly valued.

4. Beyond Reflection: Diverse Application Scenarios of Aluminum Mirrors

The versatility of the aluminum mirror extends far beyond its traditional use in homes. Its unique combination of high reflectivity, cost-effectiveness, and durability makes it indispensable across a multitude of industries and applications. Its capacity to be produced as a black aluminum mirror also opens up specific aesthetic and functional avenues.

- Architectural and Interior Design:

- Decorative Panels: Used extensively in modern interior design for creating illusions of space, enhancing light, and adding a touch of contemporary elegance in lobbies, retail spaces, and residential areas. The lightweight nature and ease of processing allow for creative architectural features.

- Wall Cladding: Large format aluminum mirror panels are used for wall cladding, providing a sleek, reflective surface that is both aesthetically pleasing and easy to maintain.

- Furniture: Integrated into tables, cabinets, and decorative items.

- Bathrooms and Gyms: Its resistance to humidity makes it ideal for bathroom mirrors, while its safety characteristics (often used with safety backing) are beneficial for fitness centers.

- Solar Energy Systems:

- Concentrating Solar Power (CSP): Aluminum mirrors are fundamental components in CSP plants, focusing sunlight onto receivers to generate heat for electricity production. Their high reflectivity and durability against outdoor elements (such as UV radiation and moisture) are crucial for the long-term efficiency of these large-scale installations.

- Solar Water Heaters: Smaller parabolic or trough mirrors are used to concentrate solar energy for residential and commercial water heating systems.

- Automotive Industry:

- Rearview Mirrors: While often chrome-coated, aluminum-based reflective layers are used in certain automotive mirror applications due to their broad spectrum reflectivity and robust nature.

- Interior Components: Smaller reflective surfaces within dashboards or lighting systems.

- Lighting and Illumination:

- Reflectors in Luminaires: Used in light fixtures to maximize light output and direct illumination precisely. Their efficiency contributes to energy savings in commercial and industrial lighting.

- Stage and Event Lighting: For special effects and light projection.

- Scientific and Industrial Instruments:

- Telescopes and Microscopes: Aluminum is a standard coating for primary and secondary mirrors in astronomical telescopes due to its good reflectivity across the visible and UV spectrums. Its relatively low cost allows for large mirror fabrication.

- Medical Devices: Components in diagnostic and surgical equipment where precise light manipulation is required.

- Projectors and Scanners: Used as reflective surfaces in optical projection systems and imaging devices.

- Electronic Displays and Smart Devices:

- Emerging applications include integration into smart mirrors, interactive displays, and augmented reality devices, where a reflective surface needs to also serve as a display screen when required.

The adaptability of the aluminium mirror glass to various shapes, sizes, and protective coatings ensures its continued relevance and expansion into new, innovative applications, showcasing its inherent value in both functional and aesthetic capacities.

5. Unmatched Advantages: Why Aluminum Mirrors Stand Out

Compared to other reflective surfaces, the aluminum mirror offers a compelling suite of advantages that contribute to its widespread adoption and superiority in many applications. These benefits encompass optical performance, durability, cost-efficiency, and environmental considerations.

- Superior Reflectivity and Broad Spectral Response:

Aluminum coatings provide excellent reflectivity across the entire visible light spectrum, typically ranging from 85% to 92%. Unlike silver mirrors, which tend to have lower reflectivity in the blue and UV spectrums and are more prone to tarnish, aluminum offers more uniform reflection across a wider range of wavelengths, including portions of the UV. This makes it ideal for general-purpose applications where broad spectrum reflection is needed, from interior design to scientific instrumentation.

- Cost-Effectiveness:

The raw materials (aluminum and glass) are relatively abundant and less expensive than silver. Furthermore, the vacuum deposition process for aluminum is highly efficient and scalable, leading to lower production costs per unit. This makes the aluminium mirror price significantly more competitive, especially for large-scale projects or high-volume production, without compromising on quality or performance for most applications.

- Lightweight and Easy to Handle:

Given that the reflective layer is an extremely thin film on a glass substrate, the primary weight comes from the glass itself. When compared to alternative reflective materials or highly polished metals, aluminum mirror glass offers a superior strength-to-weight ratio. This reduces logistical costs, simplifies installation, and is particularly advantageous in applications where weight is a critical factor, such as portable equipment, vehicle components, or large architectural installations.

- Enhanced Corrosion and Oxidation Resistance:

A key advantage of the aluminum mirror, especially compared to its silver counterpart, is its inherent resistance to oxidation and corrosion. While bare aluminum would oxidize, the application of protective layers (e.g., silicon monoxide/dioxide, or durable paints) during manufacturing effectively seals the aluminum layer from environmental exposure. This robust protection makes aluminum mirrors highly suitable for use in humid environments (like bathrooms), coastal regions, and industrial settings where silver mirrors would quickly degrade due to sulfur or chlorine compounds in the air. This significantly extends the mirror's lifespan and maintains its aesthetic and optical integrity.

- Durability and Longevity:

The protective layers not only guard against chemical attack but also provide substantial resistance against physical abrasion and scratches. This contributes to a long service life, reducing the need for frequent replacement and lowering long-term maintenance costs. Modern manufacturing processes ensure the adhesion of these layers is strong, preventing delamination over time.

- Versatility in Manufacturing:

Aluminum mirror manufacturers can easily customize the size, thickness, and shape of the glass substrate. The aluminum layer can also be fine-tuned for specific optical properties, and various protective layers can be applied to meet different environmental demands. This flexibility allows for tailor-made solutions for diverse industrial and aesthetic applications, including the production of specialized types like black aluminum mirror for unique design needs.

- Energy Efficiency in Specific Applications:

In solar concentrating applications (like CSP), the high and stable reflectivity of aluminum mirror surfaces translates directly into higher energy capture efficiency. This characteristic contributes significantly to the overall energy output and economic viability of renewable energy projects, making them a cornerstone in the clean energy transition.

These combined advantages underscore why the aluminum mirror remains a preferred choice for a broad spectrum of industries, delivering reliable performance and excellent value.

6. Choosing Your Partner: Navigating the Aluminum Mirror Manufacturers Landscape

Selecting the right supplier among numerous aluminum mirror manufacturers is a critical decision that impacts project success, product quality, and long-term reliability. A discerning buyer should evaluate potential partners based on several key criteria to ensure they receive superior products and service.

- Experience and Track Record: Look for manufacturers with a proven history in the industry. Years of operation often translate into deep expertise, refined processes, and a stable supply chain. A company like ours, with significant experience as an Aluminum mirror glass China factory custom wholesale supplier, demonstrates extensive market understanding and capability.

- Technological Capability and R&D: A leading manufacturer invests in state-of-the-art production equipment (e.g., advanced vacuum deposition machines, CNC glass processing lines) and actively engages in research and development. This commitment ensures they can produce high-performance mirrors, innovate with new coatings (like those for black aluminum mirror), and meet evolving industry standards.

- Quality Certifications and Adherence to Standards: Verify that the manufacturer holds relevant international certifications such as ISO 9001 for quality management, demonstrating their commitment to consistent quality. Furthermore, ensure their products comply with specific industry standards like ASTM (for materials) or EN (for glass in building applications). This indicates rigorous testing and quality control protocols.

- Customization Capabilities: Not all projects are standard. A strong manufacturer should offer comprehensive customization options, including varying glass thicknesses, specific dimensions, unique shapes (via CNC cutting), specialized reflective coatings, and different protective layers to meet unique performance or environmental demands. This flexibility is key for bespoke architectural or industrial applications.

- Production Capacity and Lead Times: Assess their capacity to handle your order volume and their ability to meet your project deadlines. Reliable manufacturers provide transparent lead times and have robust production lines to ensure timely delivery without sacrificing quality.

- Customer Support and After-Sales Service: Evaluate their responsiveness, technical support, and willingness to address any post-purchase concerns. A reputable manufacturer offers comprehensive support, including warranty, maintenance advice, and problem-solving assistance.

- Pricing and Value Proposition: While the aluminium mirror price is a factor, it should not be the sole determinant. Compare quotes not just on cost but also on the overall value, considering product quality, durability, customization options, and the manufacturer’s reputation. A slightly higher price might justify superior performance and longevity, leading to better long-term savings.

- Environmental and Safety Practices: In today's market, manufacturers committed to environmentally friendly production processes (e.g., lead-free paint, reduced energy consumption) and robust workplace safety standards are preferred partners.

By thoroughly evaluating these aspects, businesses can forge strong partnerships with manufacturers capable of delivering high-quality aluminum mirror products that consistently meet their specific needs and contribute to their success.

7. Tailored for Excellence: Custom Solutions and Design Flexibility

In a world of diverse applications, off-the-shelf solutions often fall short. Recognizing this, leading aluminum mirror manufacturers, including us as an Aluminum mirror glass China factory custom wholesale provider, specialize in offering comprehensive custom solutions that cater to the unique demands of architects, designers, engineers, and industrial clients. This commitment to customization ensures that every project, no matter how complex, benefits from precisely engineered reflective surfaces.

Our Customization Capabilities Include:

- Custom Sizing and Shapes: We can produce aluminum mirror panels in virtually any size, from small, intricate components for scientific instruments to massive panels for building facades. Our advanced CNC cutting and grinding capabilities allow for the creation of complex shapes, curves, and cut-outs with extreme precision, going beyond standard rectangular formats. Whether it’s a circular mirror for a specific luminaire design or a unique geometric shape for an art installation, we can deliver.

- Varying Thicknesses and Substrates: While 2mm to 6mm are standard, we can work with a wider range of glass thicknesses to meet specific structural requirements or aesthetic preferences. We also offer options for different glass substrates, such as ultra-clear low-iron glass for maximum clarity and light transmission, or tempered glass for enhanced safety and impact resistance, crucial for public spaces or high-traffic areas.

- Specialized Reflective Coatings: Beyond standard aluminum, we can apply specific reflective coatings to optimize performance for particular wavelengths or light conditions. This includes fine-tuning the aluminum layer's thickness for specific optical properties or applying specialized dielectric coatings for enhanced reflectivity or durability in specific spectral ranges.

- Protective and Backing Layers: The choice of protective layers is crucial for the mirror's longevity and performance in various environments. We offer a range of options, from single protective layers for general use to multi-layered, highly resistant coatings for harsh industrial or humid environments. For safety and additional protection, we can apply vinyl safety backing (CAT I and CAT II) which holds glass fragments together upon breakage, a critical feature for mirrors used in public areas or furniture.

- Edge Work and Finishing: We provide a full suite of edge processing options, including flat polished edges, beveled edges, pencil edges, and custom-designed decorative edges. These finishes not only enhance aesthetics but also improve safety and durability.

- Color and Aesthetic Variations: While the traditional aluminum mirror offers a bright, clear reflection, we also specialize in producing variations like the black aluminum mirror, which provides a darker, more sophisticated reflection, ideal for contemporary interior design themes or specialized visual effects. This is achieved through specific coating processes or tinted glass substrates.

- Design Consultation and Engineering Support: Our team of experts collaborates closely with clients from concept to completion. We offer technical advice on material selection, design optimization, and installation considerations, ensuring that the final product not only meets but exceeds expectations. This consultative approach minimizes risks and maximizes the functional and aesthetic potential of the mirror.

Our commitment to custom solutions means that clients are not limited by standard offerings but can realize their vision with precision-engineered aluminum mirror glass tailored to their exact specifications. This bespoke approach delivers superior performance and greater value for specialized projects.

8. Real-World Impact: Illustrative Application Cases and Success Stories

The practical application of aluminum mirror technology showcases its remarkable versatility and impact across diverse industries. Here are some illustrative examples where the unique properties of aluminum mirrors have provided significant advantages and driven success.

- Case Study 1: Large-Scale Solar Concentrator Arrays (Energy Sector)

Challenge: A leading solar energy developer required highly reflective, durable, and cost-effective mirrors for a new concentrated solar power (CSP) plant in a desert environment. The mirrors needed to withstand extreme temperatures, dust, and occasional harsh weather while maintaining high reflectivity for decades.

Solution: We provided custom-sized aluminum mirror panels with enhanced protective coatings specifically engineered for outdoor resilience. The panels were manufactured using ultra-clear glass substrates to maximize light transmission before reflection and featured a multi-layered protective coating to resist abrasion from sand and prevent oxidation due to humidity fluctuations. Our efficient manufacturing process ensured a competitive aluminium mirror price for the large volume required.

Outcome: The plant achieved optimal energy conversion efficiency, consistently meeting its power generation targets. The longevity and minimal degradation of the mirrors significantly reduced maintenance costs and contributed to a higher return on investment for the developer. This project underscored the aluminum mirror's advantage in energy efficiency and robust anti-corrosion properties.

- Case Study 2: High-End Retail Interior Design (Architectural Sector)

Challenge: A luxury retail brand sought to create an expansive, modern, and visually striking interior for its flagship store. The design concept called for large, seamless reflective surfaces that conveyed sophistication, required minimal maintenance, and could withstand high foot traffic without easily scratching or dulling.

Solution: We collaborated with the design firm to supply oversized aluminum mirror panels, including unique black aluminum mirror accents, integrated into wall features and display cases. These mirrors were produced with precision CNC cutting for perfect fitment and featured highly durable, scratch-resistant protective layers. The lightweight nature of the aluminum mirrors facilitated easier installation of the large panels compared to heavier alternatives.

Outcome: The store achieved its desired aesthetic, creating a spacious and luxurious ambiance that enhanced the customer experience. The durability of the mirrors ensured they retained their pristine appearance even after extensive use, significantly reducing cleaning and repair efforts. Customer feedback highlighted the "stunning visual impact" of the reflective surfaces.

- Case Study 3: Specialized Medical Diagnostic Equipment (Healthcare Sector)

Challenge: A medical device manufacturer needed small, highly precise, and extremely reliable mirrors for a new generation of diagnostic imaging equipment. The mirrors needed to maintain exact optical flatness and consistent reflectivity over a long operational lifespan, often in environments with strict cleanliness and sterilization protocols.

Solution: We supplied custom-fabricated aluminum mirror components with sub-millimeter tolerances and optical flatness certified to lambda/10. These mirrors underwent additional stringent cleaning and packaging procedures suitable for medical-grade applications. The choice of aluminum ensured broad-spectrum reflectivity suitable for the specific light sources used in the diagnostic process, and the robust protective layers guaranteed long-term performance without degradation.

Outcome: The manufacturer successfully integrated these mirrors into their new equipment, which received regulatory approval. The precision and stability of the mirrors contributed directly to the accuracy and reliability of the diagnostic results, leading to enhanced patient care. The long lifespan of the mirror components reduced the need for frequent replacements, contributing to the device's overall cost-effectiveness.

These cases exemplify how the advanced properties and customizable nature of the aluminum mirror, backed by expert manufacturing, lead to tangible benefits in performance, aesthetics, and operational efficiency across critical sectors.

9. Ensuring Trust and Quality: Our Commitment to Excellence ()

At the core of our operations as an Aluminum mirror glass China factory custom wholesale provider is an unwavering commitment to the Google (Expertise, Experience, Authoritativeness, Trustworthiness) standards. We believe that true quality extends beyond the product itself to encompass every facet of our interaction with clients and the broader industry.

- Expertise (E): Our team comprises seasoned professionals with deep expertise in optical physics, material science, and advanced glass processing. This includes engineers specializing in vacuum coating technologies, chemists focused on protective layer formulations, and production managers with decades of experience in large-scale glass manufacturing. We regularly engage in professional development and keep abreast of the latest advancements in aluminum mirror technology, ensuring that our products and advice are always at the cutting edge. Our technical white papers and participation in industry forums underscore our profound understanding of reflective surfaces.

- Experience (E): With a long history in the glass and mirror manufacturing industry, we have accumulated extensive practical experience through hundreds of successful projects worldwide. From supplying aluminum mirror panels for monumental architectural projects to providing precision components for sophisticated scientific instruments and high-volume orders for interior designers, our portfolio demonstrates our adaptability and capability. We actively solicit customer feedback, which informs our continuous improvement processes, ensuring our products and services are aligned with real-world application needs and exceed customer expectations. Our experience allows us to anticipate challenges and propose effective solutions, ensuring smooth project execution from inquiry to delivery.

- Authoritativeness (A): Our commitment to quality is validated by stringent international certifications. We are ISO 9001:2015 certified, affirming our robust quality management systems. Our products consistently meet or exceed global standards such as ASTM (American Society for Testing and Materials) and EN (European Norms) for glass and mirror products, including specific tests for reflectivity, durability, and safety. We have established long-term partnerships with reputable raw material suppliers and have a strong track record with leading contractors and companies across various industries, reinforcing our position as a reliable and authoritative aluminum mirror manufacturers. Our service tenure and consistent delivery of high-quality aluminium mirror glass products have built a solid reputation within the global market.

- Trustworthiness (T): Building trust is paramount. We achieve this through transparent processes, clear communication, and comprehensive customer support.

- Quality Assurance: Every batch of aluminum mirror undergoes rigorous multi-stage quality control checks, from raw material inspection to final product verification. This includes spectral analysis, adhesion tests, environmental chamber tests (humidity, temperature cycling), and visual inspections to ensure flawless surfaces and consistent performance.

- Warranty and Guarantees: We stand behind our products with comprehensive warranty policies, providing peace of mind to our clients regarding product longevity and performance. Our terms are clear and designed to instill confidence.

- Transparent Delivery Timelines: We provide realistic and reliable delivery schedules, ensuring projects stay on track. Our logistics team works diligently to ensure timely and secure global delivery of all aluminum mirror orders, minimizing transit damage.

- Responsive Customer Support: Our dedicated customer service team is available to address inquiries, provide technical assistance, and resolve any issues promptly. We believe in building lasting relationships through consistent support.

- Competitive Pricing Strategy: While focusing on superior quality, we also ensure that our aluminium mirror price remains highly competitive in the global market, offering exceptional value without compromising on performance or service.

By upholding these principles, we aim not just to be a supplier but a trusted partner, contributing to the success and long-term satisfaction of our clients in every project involving aluminum mirror products.

10. Frequently Asked Questions (FAQ) about Aluminum Mirror Technology

Here are some common questions about aluminum mirror technology, addressing technical specifications, applications, and maintenance.

Q1: What is the primary difference between an aluminum mirror and a silver mirror?

A1: The primary difference lies in the reflective coating and protective layers. An aluminum mirror uses a layer of aluminum, typically protected by silicon monoxide/dioxide and a paint layer, offering good broad-spectrum reflectivity (85-92%) and excellent resistance to oxidation and corrosion. Silver mirrors use a silver coating, which provides slightly higher reflectivity (90-95%) but is highly susceptible to tarnishing and corrosion, especially in humid or harsh environments, requiring more robust and often more expensive protective coatings to prevent "black spots" over time. Aluminum mirror is generally more durable and cost-effective for most applications.

Q2: How durable are aluminum mirrors, especially in humid environments like bathrooms?

A2: High-quality aluminum mirrors are highly durable, particularly when manufactured with robust protective layers. The initial layer of silicon monoxide or dioxide seals the aluminum from oxygen, and the final paint layer (often lead-free and waterproof) provides excellent resistance against moisture, humidity, and common cleaning agents. This makes them ideal for bathroom use, outperforming unprotected silver mirrors that can quickly degrade in such conditions. Their lifespan can easily exceed 10-15 years with proper care.

Q3: Can aluminum mirrors be used outdoors, for example, in solar energy applications?

A3: Yes, specifically engineered aluminum mirrors with enhanced protective coatings are extensively used in outdoor applications like concentrating solar power (CSP) systems. These mirrors are designed to withstand harsh environmental conditions, including UV radiation, extreme temperature fluctuations, wind, dust, and rain, while maintaining their high reflectivity for extended periods. Their anti-corrosion properties are crucial for long-term outdoor performance.

Q4: What is the significance of the "protective layers" in an aluminum mirror?

A4: The protective layers are critical for the longevity and performance of an aluminum mirror. Without them, the thin aluminum film would quickly oxidize upon exposure to air, losing its reflective properties. The initial protective layer (e.g., silicon monoxide) directly on the aluminum prevents this oxidation. The subsequent paint layer provides mechanical protection against scratches, abrasion, and resistance to moisture and chemicals, significantly extending the mirror's lifespan and maintaining its optical quality in diverse environments.

Q5: What is a black aluminum mirror, and what are its applications?

A5: A black aluminum mirror refers to an aluminum mirror that has been specifically treated or coated to achieve a darker, smoky, or subtly tinted reflective surface. This is usually achieved by applying a specific tint to the glass substrate or through specialized coating processes. Its primary applications are in interior design, luxury retail, and architectural projects where a sophisticated, understated, or avant-garde aesthetic is desired, providing a softer reflection and unique visual depth compared to traditional clear mirrors.

Q6: What are the typical thickness options for aluminum mirror glass?

A6: Standard thicknesses for aluminium mirror glass typically range from 2mm, 3mm, 4mm, 5mm, to 6mm. The choice of thickness depends on the specific application's requirements for structural integrity, weight, and aesthetic appeal. Thicker mirrors offer greater rigidity and are often preferred for large installations or where greater perceived depth is desired, while thinner mirrors are suitable for lightweight applications or where space is limited.

Q7: How does the manufacturing process ensure the quality and precision of aluminum mirrors?

A7: Quality and precision are ensured through a multi-stage, highly controlled manufacturing process. This begins with rigorous cleaning of the glass substrate to remove all contaminants. The aluminum deposition is performed in a high-vacuum chamber (PVD process) to ensure a uniform, pure, and defect-free reflective layer. Subsequent protective layers are applied and cured under controlled conditions. Throughout the process, strict quality control measures are in place, including visual inspections, reflectivity measurements, adhesion tests, and environmental durability tests, often in compliance with ISO and ANSI standards. This meticulous approach guarantees high-performance and long-lasting aluminum mirror products.

Conclusion

The aluminum mirror stands as a versatile, high-performance, and economically viable solution for a myriad of applications, from cutting-edge solar technology and precision scientific instruments to elegant architectural designs and everyday interior spaces. Its superior reflectivity, combined with inherent durability, enhanced corrosion resistance through advanced protective coatings, and a competitive aluminium mirror price point, positions it as a preferred choice over traditional alternatives.

As the industry continues to evolve, driven by demands for greater energy efficiency, aesthetic flexibility (e.g., black aluminum mirror), and sustainability, the manufacturing of aluminum mirror glass will undoubtedly see further innovations. Choosing a knowledgeable and reputable partner among aluminum mirror manufacturers, one that adheres to stringent quality standards and offers comprehensive custom solutions, is paramount for realizing the full potential of this exceptional material. With a commitment to expertise, experience, authoritativeness, and trustworthiness, we continue to deliver advanced aluminum mirror products that not only meet but exceed the demands of a dynamic global market, ensuring clarity, longevity, and value in every reflection.

References:

- Grand View Research. (2023). "Optical Mirror Market Size, Share & Trends Analysis Report By Type (Metal, Dielectric, Others), By Application (Industrial, Medical & Life Sciences, Telecommunication), By Region, And Segment Forecasts, 2023 - 2030." Retrieved from: https://www.grandviewresearch.com/industry-analysis/optical-mirror-market (Please note: Access to full report content may require subscription.)

- ISO 9001:2015 - Quality management systems — Requirements. International Organization for Standardization. Retrieved from: https://www.iso.org/standard/62085.html

- ANSI Z97.1 - Safety Glazing Materials Used in Buildings. American National Standards Institute. (Note: Specific content usually requires purchase or subscription.)

Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu