Float glass is a cornerstone of modern architecture and various industrial applications, celebrated for its impeccable clarity, uniform thickness, and versatile functionality. The manufacturing process of float glass is both an art and a science, refined over decades to produce a product that meets rigorous quality standards. This article delves into the complexities of float glass manufacturing, offering an insightful exploration based on real-world experiences and authoritative knowledge.

The float glass manufacturing process begins with the careful selection and preparation of raw materials. Silica sand, soda ash, dolomite, and limestone are meticulously measured and combined to form a batch. The precision in this initial step cannot be overstated; each component must meet specific chemical criteria to ensure the final product's quality. Industry experts prioritize consistency in raw materials to prevent defects such as bubbles and fractures in the glass.

Once the batch is prepared, it is fed into a furnace where it reaches temperatures as high as 1700°C. This high-temperature environment serves to melt the batch into a molten glass form. The expertise required to maintain optimal furnace conditions is significant, as minor fluctuations can lead to imperfections. Modern manufacturing employs sophisticated sensors and AI-driven controls to ensure consistency, demonstrating the process's authoritative edge.

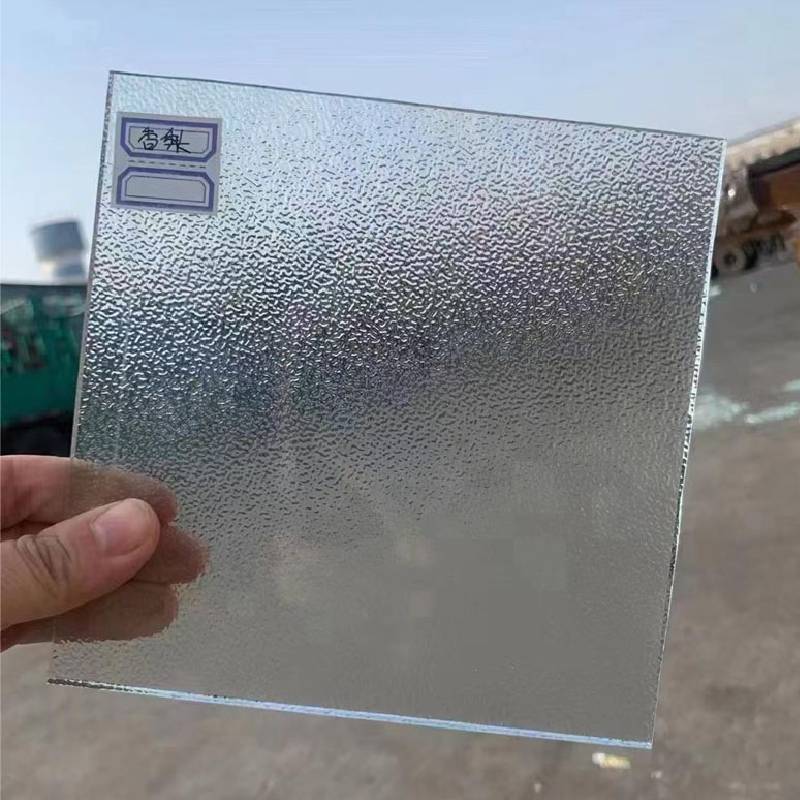

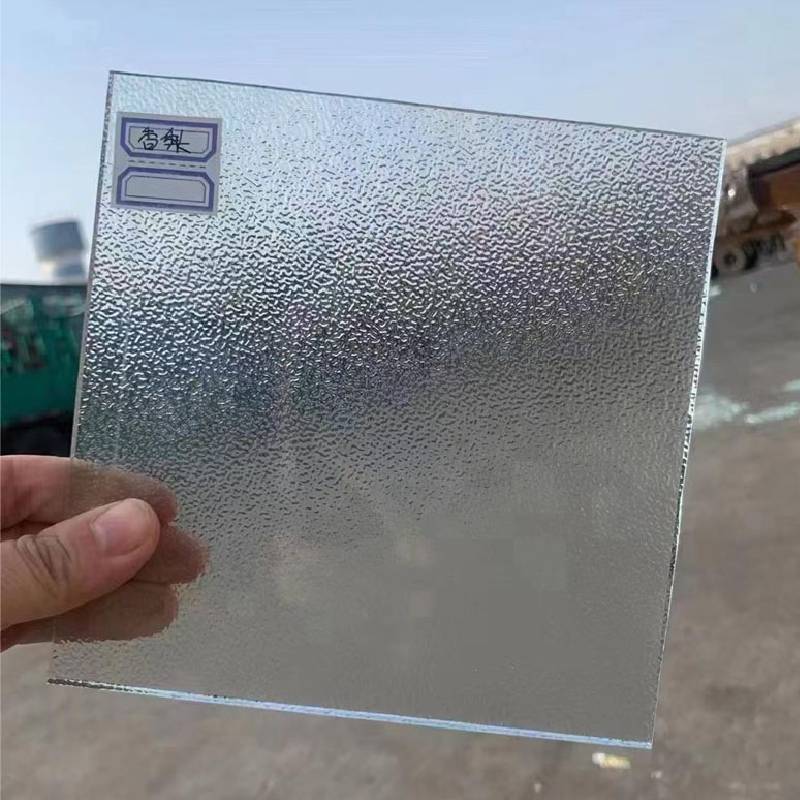

The molten glass is then transported to a bath of molten tin. Here, it literally floats, owing to the density difference, allowing gravity to naturally spread and even out the glass to a uniform thickness. This phase is what gives float glass its name and is crucial for achieving the smooth and flawless surface that characterizes high-quality float glass.

float glass manufacturing process

Controlled cooling, or annealing, is critical in the next stage of the process. The ribbon of glass is gradually cooled in a controlled manner inside an annealing lehr, which prevents the development of internal stresses that could lead to breakage. It is at this stage that real-time data analytics are invaluable, providing operators with the information needed to adjust conditions and maintain structural integrity.

As the glass continues through the manufacturing line, it undergoes rigorous quality assurance checks, including optical inspections and stress testing. Each sheet is examined for clarity, flatness, and any imperfections. The best float glass manufacturers employ state-of-the-art laser technology to detect even the slightest deviations, underscoring the importance of expertise and authoritativeness in producing top-tier products.

Sustainability has also become a paramount consideration in modern float glass production, with many facilities now incorporating recycling processes and energy-efficient practices. By reusing glass cullet and optimizing energy consumption, manufacturers reduce their environmental footprint — a practice that not only reflects expertise but also builds trust with environmentally-conscious consumers.

In conclusion, the float glass manufacturing process is a finely-tuned operation that combines raw material expertise, advanced engineering, and comprehensive quality control. It's a field where continued innovation meets traditional craftsmanship, ensuring that each pane of glass not only meets but exceeds industry standards. The evolution of this process highlights the importance of trusted methodologies and authoritative knowledge to produce a product that is both functional and aesthetically pleasing. The result is a material integral to the development of modern infrastructure and design, paving the way for future advancements in glass technology.

Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu