Understanding Plain Float Glass Properties and Applications

Plain float glass is a fundamental material in the construction and manufacturing industries, celebrated for its simplicity and versatility. This type of glass is created through the float glass process, a method that involves floating molten glass on top of molten tin. This process results in a smooth, flat surface that is essential for a variety of applications, from windows to decorative objects.

One of the defining features of plain float glass is its clarity. The float glass process produces a product with minimal impurities, allowing for high levels of light transmission without distorting the view. This transparency makes it ideal for architectural applications. Architects and builders favor plain float glass for windows, facades, and glass walls as it allows natural light to penetrate interiors while providing a clear view of the outside.

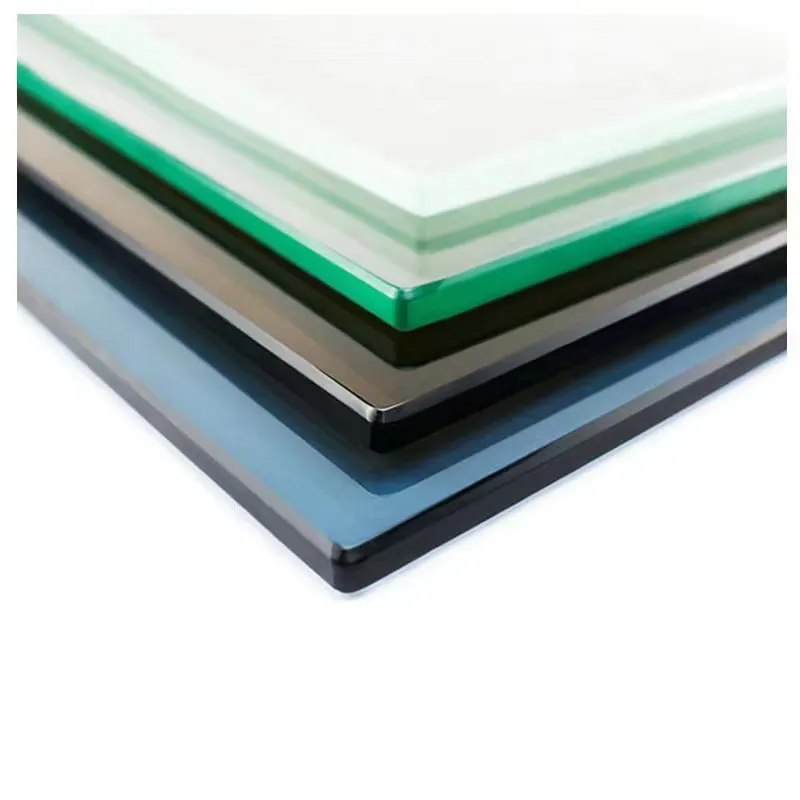

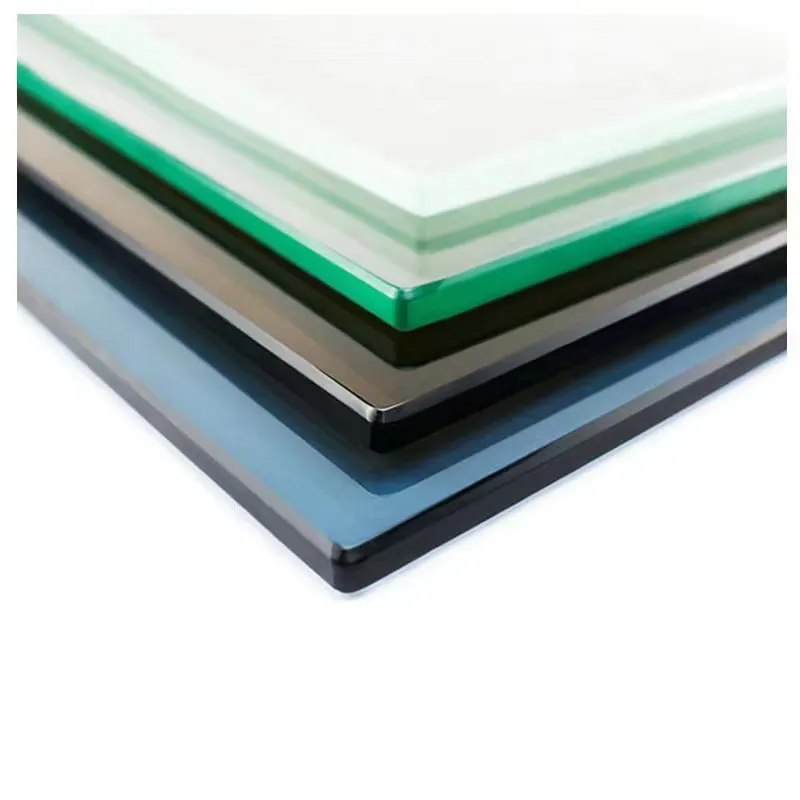

The physical properties of plain float glass contribute to its wide array of uses. It is available in various thicknesses and sizes, allowing for customization based on specific project requirements. Moreover, float glass possesses good resistance to weather conditions, making it suitable for exterior applications. However, it is important to note that while plain float glass is robust in terms of its optical properties, it is more vulnerable to impact and, compared to tempered or laminated glass, lacks significant strength and safety features.

plain float glass

The manufacturing process of plain float glass begins with melting raw materials, such as silica sand, soda ash, and limestone, at high temperatures

. The molten glass is then carefully poured onto a bath of molten tin, where it spreads out to form a flat sheet. After cooling, the glass is cut into desired sizes and may be further processed to meet specific requirements, such as coating or finishing for enhanced performance.

In addition to its use in buildings, plain float glass has applications in various industries. It is commonly used in furniture design, such as tabletops and shelves, where its aesthetic appeal and functionality come into play. Furthermore, it is widely employed in the automotive sector for windshields and windows, ensuring clear visibility for drivers and passengers alike.

Sustainability is becoming an increasingly important aspect of glass production, including plain float glass. Manufacturers are now focusing on reducing energy consumption during production and incorporating recycled materials into their processes. This shift not only minimizes environmental impact but also caters to the growing market demand for eco-friendly building materials.

In conclusion, plain float glass is a remarkable material that combines aesthetic appeal with functional versatility. Its clarity, ease of customization, and adaptability make it a staple in various sectors, particularly in architecture and design. As industries continue to evolve and prioritize sustainability, the methods of producing and utilizing plain float glass will likely advance, ensuring its place as an essential component of modern life.

Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu