The float glass manufacturing process stands as a testament to the seamless integration of innovation and engineering excellence. Float glass, omnipresent in architectural and automotive applications, is produced through a method that has undergone continuous refinement to ensure quality and sustainability. This process not only exemplifies technical prowess but also underscores a commitment to advancing the built environment with reliable materials.

The float glass manufacturing process begins with the careful selection of raw materials, primarily silica sand, soda ash, dolomite, limestone, and other minor ingredients. These materials are meticulously weighed and mixed into a batch, which is then fed into a furnace. The furnace operates at extreme temperatures exceeding 1,700 degrees Celsius, where the batch is melted to form molten glass.

One of the unique aspects of the float glass process is the use of a molten tin bath. The molten glass is carefully poured onto the surface of the molten tin, where it spreads out and forms a perfect sheet. This step is crucial as it allows the glass to achieve a uniform thickness and incredibly smooth surfaces, a hallmark of float glass that distinguishes it from other types of glass. The engineering expertise required to maintain optimal temperatures and precise control of glass and tin flow demonstrates both technical proficiency and industry know-how.

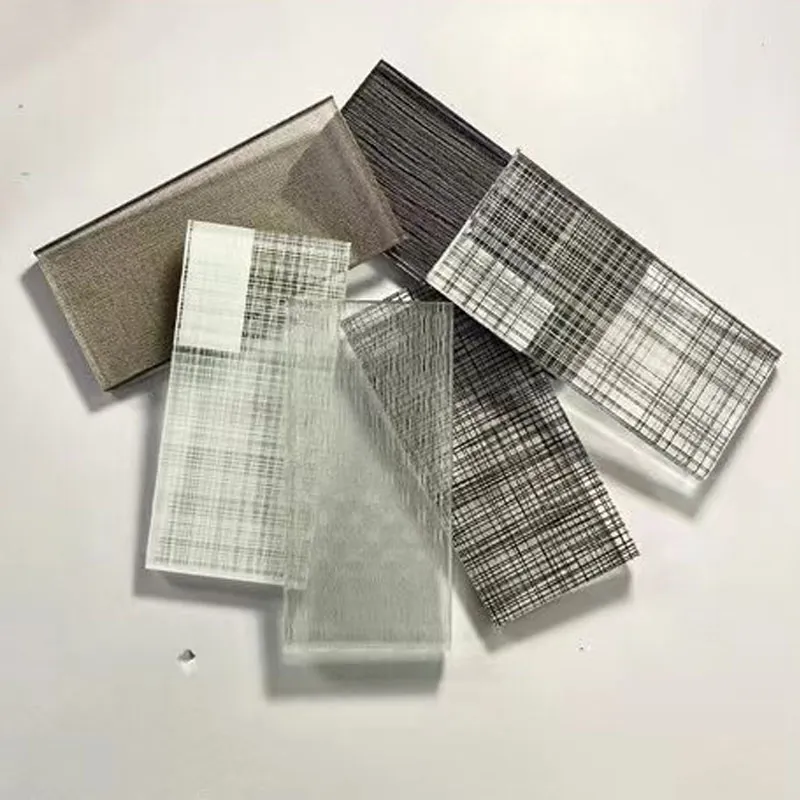

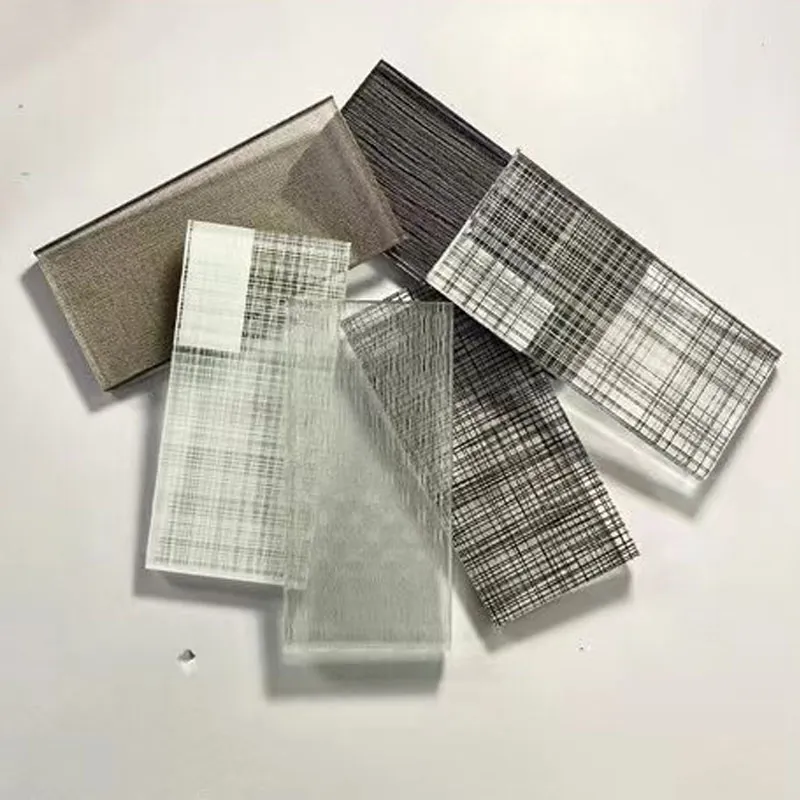

As the glass sheet progresses along the tin bath, it enters the annealing lehr. This critical phase ensures that the glass cools gradually to reduce internal stresses, which can diminish the glass's structural integrity if not properly addressed. The ability to control the cooling rate of the glass requires in-depth knowledge of material science, showcasing expert authority in manufacturing practices. Annealing transforms the glass into a robust and durable material, ready for cutting, coating, or further fabrication into specialized products such as insulated glass units or laminated safety glass.

float glass manufacturing

Product consistency and quality are paramount in float glass production. Leading manufacturers employ advanced quality control measures, including online inspections using high-tech scanning systems to detect surface imperfections and verify dimensional accuracy. These technologies reflect a commitment to trustworthiness, as customers rely on manufacturers to deliver glass that meets stringent specifications and safety standards. Being transparent and proactive about quality assurance helps build a reputation for reliability and excellence in the market.

Sustainability is becoming an increasingly significant consideration in the float glass industry. The industry is investing in more energy-efficient furnaces and looking to reduce its carbon footprint through recycling initiatives. By emphasizing eco-friendly practices, manufacturers illustrate responsibility towards environmental stewardship, enhancing trustworthiness with consumers who are environmentally conscious.

Moreover, the ability to innovate with coatings and treatments such as Low-E or anti-reflective finishes adds a layer of technology-driven enhancement to the product. These advancements not only improve the performance of the glass, meeting energy-efficiency demands but also reinforce the manufacturer's expertise in adapting to modern building requirements.

In conclusion, the float glass manufacturing process is a blend of science, art, and dedication to quality improvement. By focusing on precision, efficiency, and sustainable practices, the float glass industry not only demonstrates supreme expertise and authority but also fosters enduring trust with architects, builders, and end-users who rely on this remarkable material to bring their visions to life. Through continuous innovation and a commitment to excellence, float glass manufacturers uphold their responsibility to the future of construction and design.

Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu