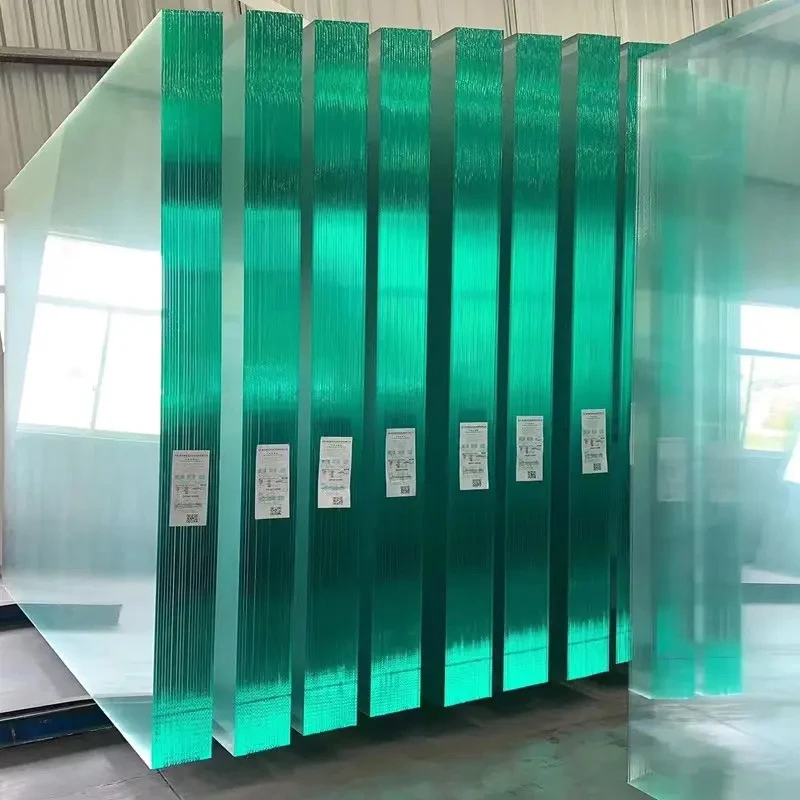

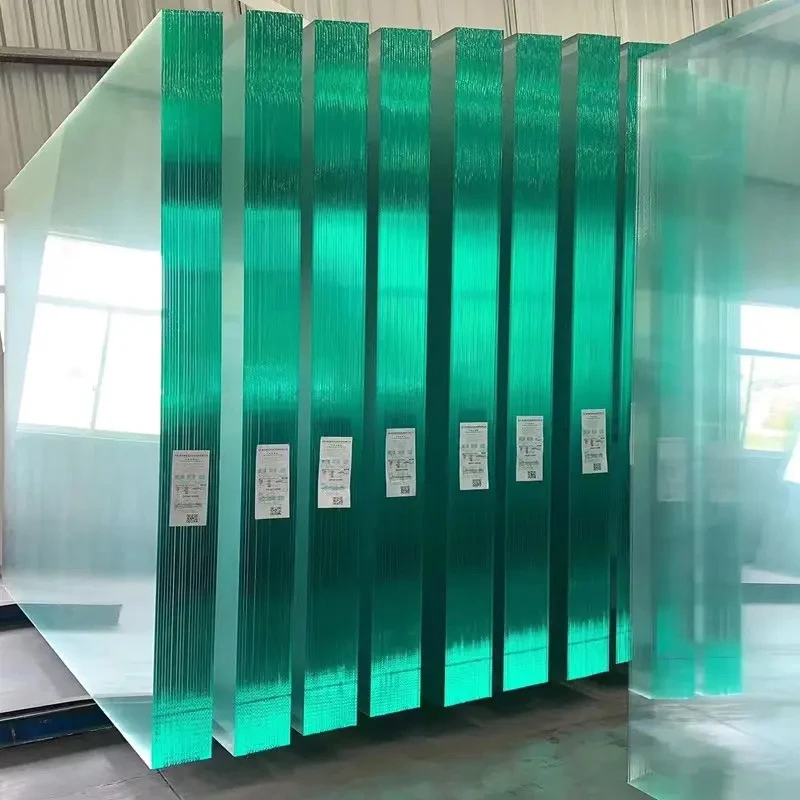

Understanding the Float Process

In the world of manufacturing and material science, the term float process may not be commonly recognized outside of specific industries, but it is a crucial concept in various applications. The float process refers to a method used mainly in producing quality materials such as glass, metals, and certain types of plastics. By understanding this technique, one can appreciate its role in enhancing product performance and manufacturing efficiency.

The float process is primarily associated with the production of flat glass. This technique was developed in the mid-20th century and has since revolutionized the glass-making industry. The process involves pouring molten glass onto a bed of molten tin, where the glass floats and spreads out evenly, creating a smooth and flat surface. The glass sheet’s thickness can be controlled by adjusting the speed at which it moves over the molten tin, allowing for a highly uniform product.

One of the most significant advantages of the float process is the quality of the glass produced. Traditional glass-making methods often resulted in imperfections such as bubbles, ripples, and thickness variations. In contrast, the float process produces glass sheets that are remarkably smooth, clear, and of consistent thickness. This has made it the preferred method for creating glass used in windows, mirrors, and other applications where clarity and uniformity are essential.

Beyond aesthetics, the float process contributes to the overall strength and durability of glass products. The controlled environment in which the glass is formed minimizes stress points, making the final product less prone to breakage. Consequently, glass manufactured through the float process is often used in high-performance applications, including automotive and architectural glass, where safety and stability are paramount.

float process

The float process is not limited to glass; it also finds applications in the production of certain metals and plastics. For instance, when producing aluminum, a modified version of the float process can be employed to create sheets of aluminum that are free of imperfections and suitable for various uses, including packaging and construction. Similarly, in the realm of plastic manufacturing, the float process can help produce high-quality, uniform sheets of material that serve as substrates for products ranging from electronics to consumer goods.

Another key aspect of the float process is its contribution to waste reduction and energy efficiency. Traditional methods of manufacturing often involve significant waste due to excess material and energy consumption. The float process, by contrast, allows for better control over material use, leading to a more sustainable manufacturing approach. As industries increasingly prioritize sustainability, techniques like the float process are becoming vital in minimizing environmental impact.

Moreover, the adaptability of the float process allows for innovation in product design and engineering. As manufacturers continue to experiment with materials and techniques, the float process offers a foundation for developing new types of glass and alternative materials that meet specific market needs while maintaining quality. This versatility opens doors to advancements in industries such as energy, packaging, and consumer electronics.

In conclusion, the float process is a critical technique in the manufacturing of flat glass, metals, and plastics. Its ability to produce high-quality, uniform materials contributes significantly to various industries, enhancing product durability, aesthetics, and performance. With the growing emphasis on sustainability and efficiency in manufacturing, the float process will likely continue to play a vital role in advancing material science and engineering. As technology progresses, we can anticipate further innovations stemming from this fundamental manufacturing technique, ensuring that the float process remains relevant and essential for years to come.

Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu