The Plate Glass Manufacturing Industry An Overview

Plate glass, a flat glass product characterized by its clarity and smooth finish, plays an essential role in various sectors, including architecture, automotive, and decorative applications. The plate glass manufacturing industry has evolved significantly over the years, driven by advancements in technology, changing consumer preferences, and increasing demand for sustainable and energy-efficient products. This article explores the key aspects of plate glass manufacturers, their processes, challenges, and future trends.

Historical Context

The production of plate glass dates back to ancient civilizations, but the modern manufacturing techniques began to take shape in the 17th century. Initially, plate glass was produced using labor-intensive methods, leading to high costs and variable quality. However, the introduction of the float glass process by Sir Alastair Pilkington in 1952 marked a revolutionary step in plate glass manufacturing. This technique involved floating molten glass on molten tin, resulting in a smoother surface and superior optical quality. Today, the float glass method remains the dominant production technique for plate glass.

Manufacturing Process

The manufacturing of plate glass involves several critical steps, including raw material preparation, melting, forming, annealing, and finishing. The primary raw materials used in the production of plate glass are silica sand, soda ash, and limestone. These materials are mixed and heated in a furnace at high temperatures to create molten glass.

Once the glass reaches a liquid state, it is either poured into a float bath or formed into flat sheets using various technologies such as drawing and rolling. The glass sheets are then cooled slowly in a controlled environment through a process known as annealing. This step is crucial as it relieves internal stresses that could lead to breakage. After cooling, the glass is cut into required dimensions, polished, and subjected to additional treatments, such as coatings for energy efficiency or safety.

Industry Challenges

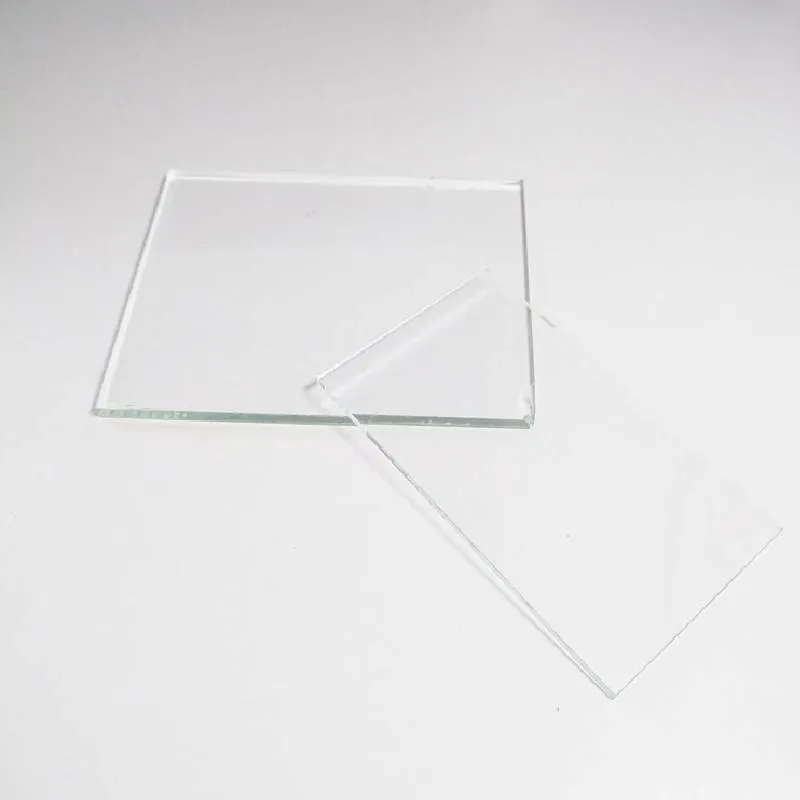

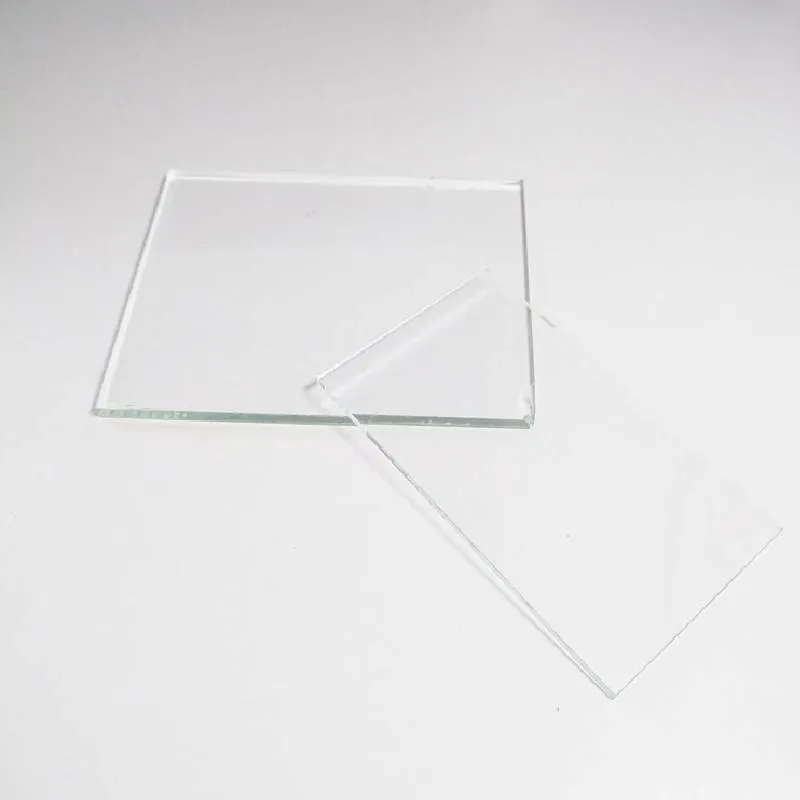

plate glass manufacturers

Despite its growth, the plate glass manufacturing industry faces several challenges. One of the most pressing issues is the volatility of raw material prices. The costs of silica sand and other essential materials can fluctuate significantly, impacting profitability. Additionally, sustainability has become a critical concern. Manufacturers are under increasing pressure to reduce their carbon footprint and adopt environmentally friendly practices. This includes optimizing energy consumption during production, recycling glass waste, and developing new processes that reduce pollution.

Labor availability is another challenge. The manufacturing sector has seen a decline in skilled labor, which creates a skill gap in operating complex machinery and maintaining quality standards. Manufacturers must invest in training and development to ensure their workforce is equipped for modern production techniques.

Future Trends

As the industry looks ahead, several emerging trends are likely to shape the future of plate glass manufacturing. One such trend is the growing demand for advanced glazing solutions in architecture. Energy-efficient glass that minimizes heat loss and improves insulation is increasingly sought after, prompted by global energy conservation efforts.

Smart glass technology is another area of potential growth. This innovative glass can change its properties in response to environmental conditions, such as light and temperature. As smart buildings become more prevalent, the demand for such technology in plate glass products is expected to increase.

Moreover, the integration of automation and artificial intelligence in manufacturing processes will enhance efficiency and reduce operational costs. Advanced machinery can help streamline production lines, and AI can improve quality control and predictive maintenance, minimizing downtime.

Conclusion

The plate glass manufacturing industry stands at the crossroads of tradition and innovation. With a rich history and a robust manufacturing process, it has paved the way for numerous applications across various sectors. However, challenges such as raw material volatility, sustainability, and labor shortages must be addressed to ensure long-term viability. By embracing technological advancements and adapting to emerging market trends, plate glass manufacturers can continue to thrive in an ever-evolving landscape. As the industry moves forward, its commitment to quality, sustainability, and innovation will be paramount in shaping the future of plate glass.

Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu