The Process of Making Tempered Glass

Tempered glass, known for its strength and safety features, is a popular choice in modern architecture and design. The process of making tempered glass involves several critical steps designed to enhance its durability and resistance to thermal stress. This article will outline the stages involved in producing tempered glass and highlight its benefits.

The first step in manufacturing tempered glass is selecting the raw materials. High-quality float glass is commonly used due to its excellent optical clarity and uniform thickness. The glass is cut into specific sizes according to the intended application, be it for windows, doors, or other architectural installations. Precision in cutting is crucial because the edges of the glass later undergo treatments that affect its overall integrity.

Once the glass panels are cut to size, they are thoroughly cleaned to remove any impurities. This cleaning step is essential because even minute particles can compromise the glass’s strength during the tempering process. After cleaning, the glass panels are inspected for any surface defects, such as scratches or bubbles, which would weaken the final product.

The next phase is the heating process, where the glass is gradually heated to a temperature of around 600 to 700 degrees Celsius (about 1112 to 1292 degrees Fahrenheit). This rapid heating is accomplished using specialized furnaces. The objective is to elevate the temperature uniformly to ensure an even distribution of heat throughout the glass. Uneven heating can lead to weak points, which counteracts the purpose of tempering. This step is crucial as it brings the glass to a state where it can undergo the subsequent quenching process effectively.

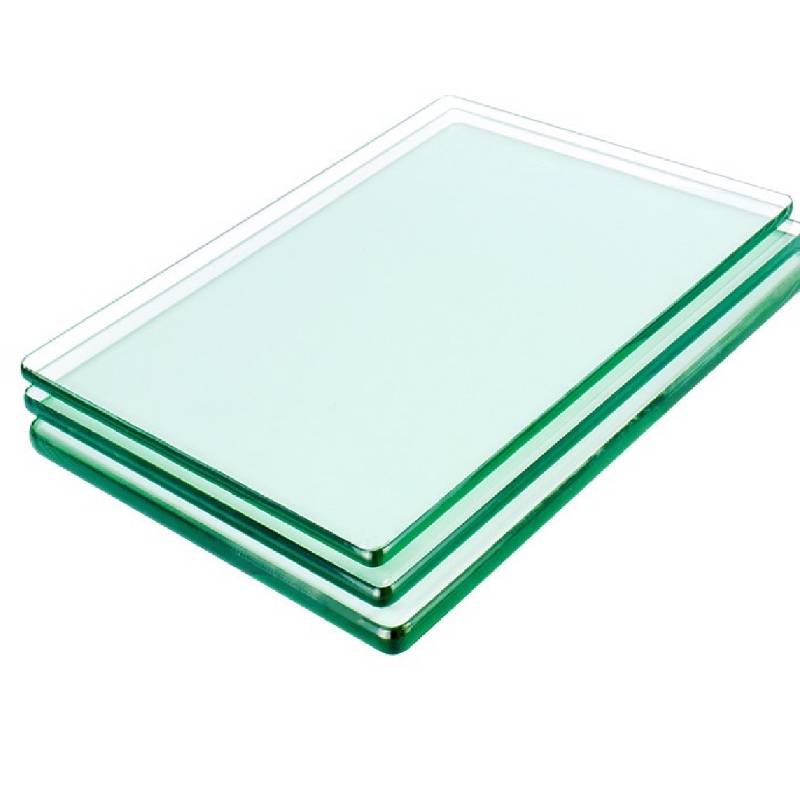

process of making tempered glass

Following the heating stage, the glass enters the quenching phase, which involves rapidly cooling the heated glass using high-pressure air. This sudden drop in temperature creates compressive stresses on the surface while allowing the interior to cool more slowly. This process results in tempered glass that is substantially stronger than regular glass. In fact, tempered glass can withstand impacts and thermal fluctuations much better than its non-tempered counterpart.

Once the quenching is complete, the tempered glass is allowed to stabilize at room temperature. After stabilization, the final quality checks are performed to ensure the glass meets the required safety and quality standards. This includes checking for strength, optical clarity, and thermal resistance. Only after passing these inspections can the glass be ready for shipment and installation.

The benefits of tempered glass are numerous. First and foremost, its strength makes it suitable for applications where safety is paramount, such as in shower doors, glass doors, and facades. In the event of breakage, tempered glass shatters into small, blunt pieces instead of sharp shards, reducing the risk of injury. Additionally, tempered glass is highly resistant to thermal stresses, which makes it ideal for environments with significant temperature variations.

In conclusion, the process of making tempered glass is a meticulous series of steps that transform raw glass into a robust, safe, and functional material. Through careful selection, heating, and quenching, manufacturers create glass that meets the demands of modern construction and design, ensuring both aesthetic appeal and safety for users.

Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu