The Tinted Glass Factory A Blend of Art and Technology

In today's world, where aesthetics and functionality go hand in hand, tinted glass has garnered immense popularity across multiple sectors. Tinted glass, which is glass that has been treated to reduce sunlight and glare, is not only an essential material for architectural designs but also a critical component in automotive industries, electronics, and various consumer products. At the heart of this booming industry lies the tinted glass factory, a space where creativity meets advanced technology.

The Manufacturing Process

The tinted glass manufacturing process begins with the selection of raw materials. High-quality silica sand, soda ash, and lime are combined and melted at extremely high temperatures to form glass. Once the raw glass has cooled and solidified, the tinting process begins. The tint can be introduced during the melting stage by adding colorants or may be applied post-production through various techniques, including film application or surface coating.

One of the most common ways to tint glass is through the use of metal oxides. By introducing these oxides, manufacturers can achieve a range of colors and shades, from light greys to deep blacks. Each tint serves a functional purpose—enhancing privacy, reducing glare, and improving energy efficiency by reflecting solar heat. Additionally, modern tinted glass can be treated to increase strength and durability, making it a favorite choice for both residential and commercial structures.

Technological Innovations

The tinted glass industry has seen remarkable technological advancements in recent years. With the installation of state-of-the-art machinery, tinted glass factories can produce large quantities of high-quality glass in a shorter period. Automation has streamlined the production line, allowing for precise control over the tinting process. Robotics are now commonly used for cutting and shaping glass, while computer software analyzes the quality and ensures consistency across batches.

Moreover, innovations in nanotechnology have led to the development of trend-setting self-tinting glass. This pioneering product adjusts its tint in response to changing light conditions. By utilizing photochromic or thermochromic materials, this glass not only enhances energy efficiency but also provides a dynamic aesthetic appeal that changes throughout the day.

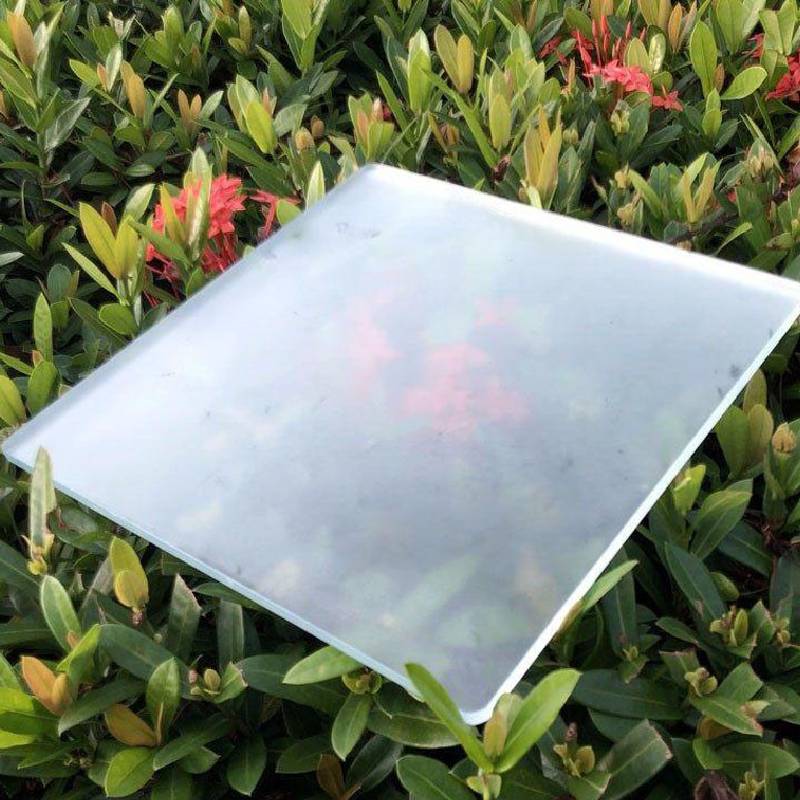

tinted glass factory

Sustainable Practices

As environmental awareness grows, tinted glass factories are also placing a stronger emphasis on sustainability. Efforts are being made to recycle waste glass and minimize energy consumption during production. Many factories are now implementing closed-loop systems that reduce water usage and recycle excess materials back into the production line.

In addition, manufacturers are increasingly focused on producing eco-friendly glass that complies with stringent environmental regulations. This includes the use of non-toxic pigments for tinting and energy-efficient manufacturing processes that reduce the overall carbon footprint of production. By adopting sustainable practices, tinted glass factories are not only meeting consumer demand but also contributing positively to the environment.

The Market Demand

The demand for tinted glass is rapidly growing in various sectors, particularly in construction and automotive. Homeowners and builders are increasingly opting for tinted windows to enhance privacy and reduce energy costs. Furthermore, in commercial buildings, tinted glass is a staple for creating a modern, sleek appearance while delivering substantial energy savings.

In the automotive sector, tinted windows are favored for their ability to provide comfort to passengers and protect interiors from fading. Stricter regulations regarding UV protection have also led automakers to incorporate tinted glass into their vehicle designs.

Conclusion

The tinted glass factory represents a confluence of artistry and modern technology. As demand continues to rise across diverse applications, innovation and sustainability remain at the forefront of this industry. From aesthetic appeal to functional benefits, tinted glass plays a crucial role in contemporary architecture and design. With ongoing advancements in manufacturing techniques and materials, the future of tinted glass looks promising, poised to meet the evolving needs and preferences of consumers worldwide.

Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu