The flat glass manufacturing industry is a cornerstone of modern architecture and design, playing an essential role in creating transparent, durable surfaces for various applications. From residential homes to towering skyscrapers, flat glass is omnipresent, and advancements in its manufacturing processes continue to bolster its indispensability across sectors.

A definitive experience in integrating flat glass within the architecture and design industries reveals the transformative powers of this material. Architects and designers leverage its sleek and clear aesthetic, allowing for an influx of natural light, which not only enhances the visual appeal of structures but also improves energy efficiency by reducing the dependency on artificial lighting. Moreover, the use of flat glass in double glazing significantly enhances thermal insulation, contributing to a building's overall energy performance.

From an expertise perspective, understanding the technicalities of flat glass manufacturing is crucial.

The process primarily involves the float glass technique, which was pioneered in the 1950s. This method entails floating molten glass on a bed of molten tin, which results in a perfectly flat and uniform surface. This technique has been refined over the decades, emphasizing energy efficiency and reducing emissions, aligning with global sustainability goals. Furthermore, coated glass products created through advanced techniques like magnetron sputtering enhance functionalities like thermal insulation and solar control, showcasing the vast potential in product customization.

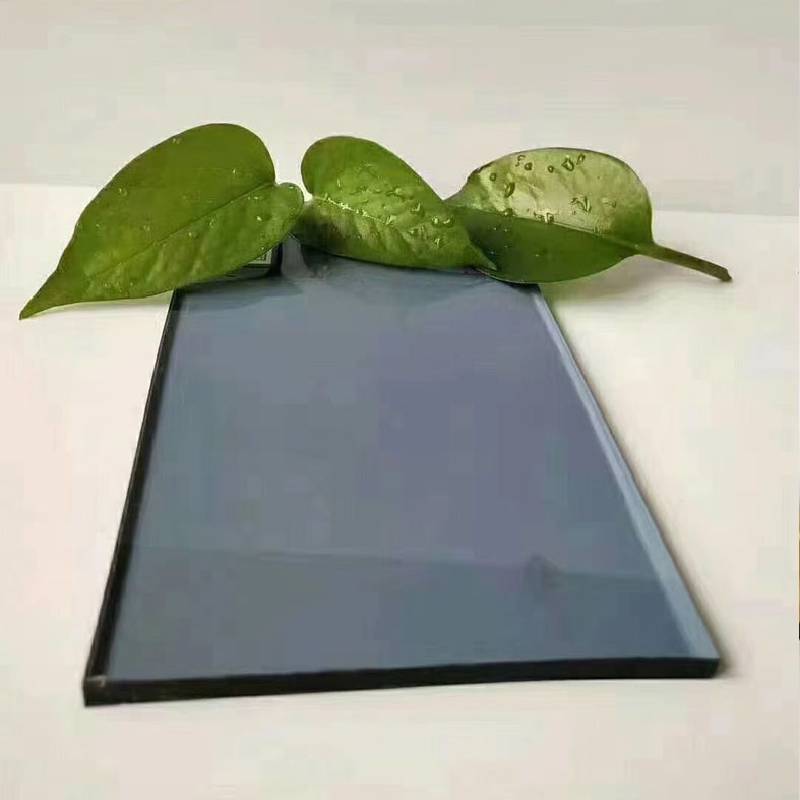

flat glass manufacturing

The authoritativeness of flat glass as a material of choice in construction is underscored by industry standards and certifications that signify compliance with safety and performance benchmarks. Organizations such as the Glass and Glazing Federation set rigorous standards for impact resistance and thermal performance, ensuring that flat glass installations are both safe and efficient. Adhering to these standards is pivotal for manufacturers to gain trust and loyalty from builders and consumers alike.

Trustworthiness in the flat glass manufacturing landscape stems from the industry's commitment to ethical practices and sustainable solutions. Many leading manufacturers invest in recycling technologies, minimizing waste, and decreasing carbon footprints. This eco-friendly approach not only enhances the reputation of flat glass manufacturers but also aligns with the increasing demand for green building materials. By using recyclable materials and energy-efficient production methods, manufacturers demonstrate a genuine dedication to preserving the environment, fostering consumer trust in their products.

In summary, flat glass manufacturing combines cutting-edge technology with an enduring focus on sustainability, shaping the future of construction and design. The industry exemplifies innovation, delivering products that blend functionality with aesthetic appeal. Mastery in flat glass manufacturing is not just about producing a product but about offering solutions that meet the growing aspirations of energy efficiency, design flexibility, and environmental stewardship. As technology evolves, the potential applications for flat glass expand, promising a future where buildings are more connected to their environment both visually and energetically. Through continuous innovation and adherence to stringent standards, the flat glass manufacturing industry stands as a testament to modern engineering and design excellence.

Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu