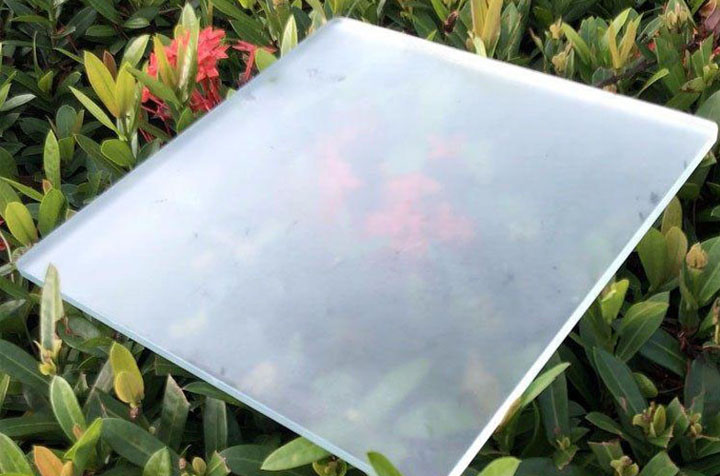

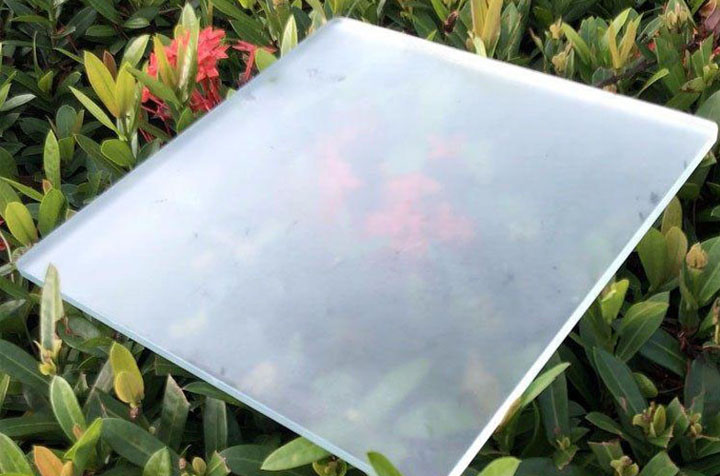

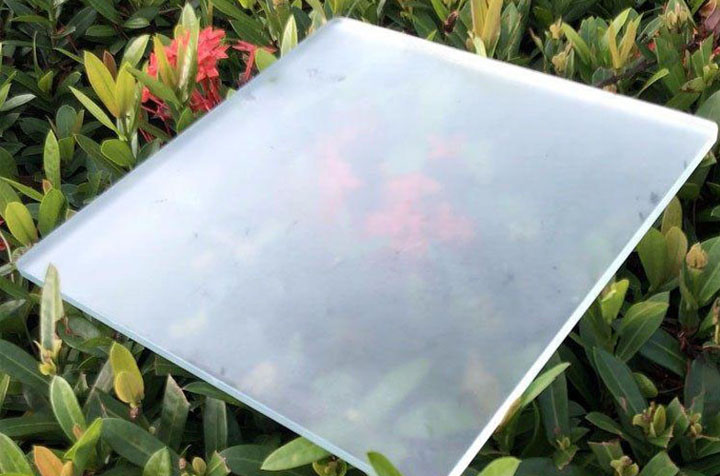

Sheet glass manufacturing is an intricate process that has revolutionized the construction and technology industries. It involves the production of large, flat panes of glass, commonly used in windows, doors, mirrors, and various architectural applications.

The journey of sheet glass begins with raw materials, primarily silica sand, which is the primary component of glass. Other ingredients such as soda ash and limestone are added to lower the melting point of the sand and to remove impurities. These materials are carefully measured and mixed together in a giant furnace, where they are heated to an intense temperature of around 1700 degrees Celsius, transforming them into molten glass.

The molten glass is then fed into a continuous ribbon formation machine, known as a float bath. This innovative technique, introduced by Sir Alfred Ford in the 1950s, is where the term 'float glass' comes from. The molten glass floats on a bed of molten tin, allowing it to spread evenly and form a smooth, level surface. As the glass cools, it solidifies while maintaining its uniform thickness.

After passing through the float bath, the glass is slowly cooled in a annealing lehr, a temperature-controlled chamber. Annealing is crucial as it relieves internal stresses within the glass, making it more durable and less prone to cracking. Once cooled, the glass is cut to the desired size and shape using specialized machinery, ensuring precision and accuracy Once cooled, the glass is cut to the desired size and shape using specialized machinery, ensuring precision and accuracy

Once cooled, the glass is cut to the desired size and shape using specialized machinery, ensuring precision and accuracy Once cooled, the glass is cut to the desired size and shape using specialized machinery, ensuring precision and accuracy

sheet glass manufacturing

sheet glass manufacturing.

Quality control is a vital aspect of sheet glass manufacturing. Each pane undergoes rigorous inspections for defects, thickness consistency, and optical clarity. Any faulty pieces are rejected, and the high-quality sheets are then packaged and transported to various industries worldwide.

Sheet glass manufacturing has significantly evolved over the years, incorporating eco-friendly practices. Today, manufacturers recycle waste glass, reducing the need for raw materials and minimizing environmental impact. Additionally, energy-efficient furnaces and advanced recycling technologies have been developed to minimize emissions and conserve resources.

In conclusion, sheet glass manufacturing is a complex blend of science, technology, and artistry. From the fusion of raw materials to the precision cutting and stringent quality checks, every step contributes to the creation of a product that not only provides aesthetic appeal but also serves essential functions in insulation, safety, and energy efficiency. The industry continues to innovate, pushing the boundaries of glass technology for a sustainable future.

Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu

Once cooled, the glass is cut to the desired size and shape using specialized machinery, ensuring precision and accuracy Once cooled, the glass is cut to the desired size and shape using specialized machinery, ensuring precision and accuracy

Once cooled, the glass is cut to the desired size and shape using specialized machinery, ensuring precision and accuracy Once cooled, the glass is cut to the desired size and shape using specialized machinery, ensuring precision and accuracy