Tempered glass production stands at the intersection of art and science, embodying precision, mastery, and innovation. It is this unique convergence that has fueled its unparalleled growth and demand in construction, automotive, and consumer electronics. Each sheet of tempered glass tells a story of rigorous manufacturing processes and expert craftsmanship, offering a product that seamlessly combines strength and elegance.

Crafting tempered glass begins with selecting premium quality raw materials – primarily silica sand, soda ash, and lime. These elements are meticulously measured and mixed before being melted at extremely high temperatures. This melting process is crucial, as achieving homogeneity ensures the final product meets the stringent safety and durability standards expected in all applications.

Once the glass is formed, the tempering process begins, which sets tempered glass apart from its standard counterpart. The annealing lehr propels the glass through cycles of intense heating—generally reaching temperatures above 600°C—followed by rapid cooling. This dual-stage process induces compressive stresses on the surface while tension persists internally. Such stress distribution is essential for the glass's renowned strength and shatter-resistant qualities, making it up to five times stronger than regular glass.

Real-world expertise in managing this sophisticated tempering process is indispensable. Careful monitoring of temperature gradients and cooling rates requires seasoned professionals with a nuanced understanding of how minor alterations can significantly impact the final product's performance attributes. Expertise in these operations ensures that the glass not only achieves the desired mechanical properties but also maintains optical clarity—key in applications where visibility and aesthetic appeal are paramount.

The authoritativeness in tempered glass production is underscored by adherence to global safety standards, such as ANSI Z97.1, EN 12150, and ASTM C1048. Knowledge of these standards is not just a formality but a testament to the commitment of manufacturers to safety and quality assurance. Compliance guarantees that the tempered glass can withstand impacts, thermal stresses, and other environmental factors, thereby elevating consumer trust in its reliability across various sectors, from the towering facades of skyscrapers to the screens encasing personal gadgets.

tempered glass production

Trustability, a cornerstone of tempered glass manufacturing, is fostered through rigorous quality control protocols at every production stage. Advanced testing methods—such as fragment retention tests, surface tension assessments, and visual inspections—are employed to validate that every piece of glass meets precise specifications. Manufacturers often implement tracking systems to trace each glass panel's production history, providing transparency and accountability that fortifies consumer confidence.

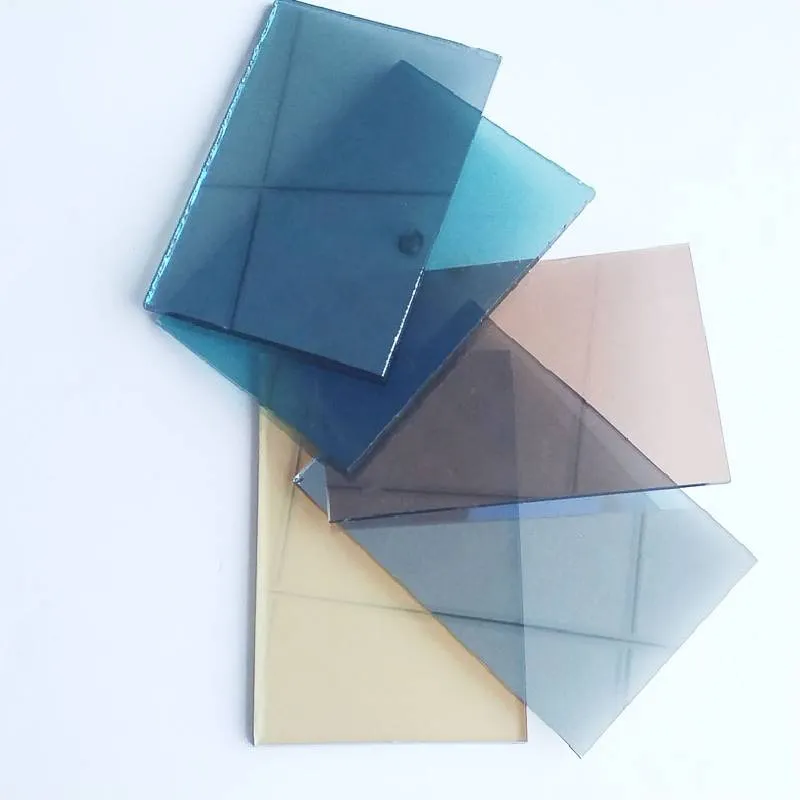

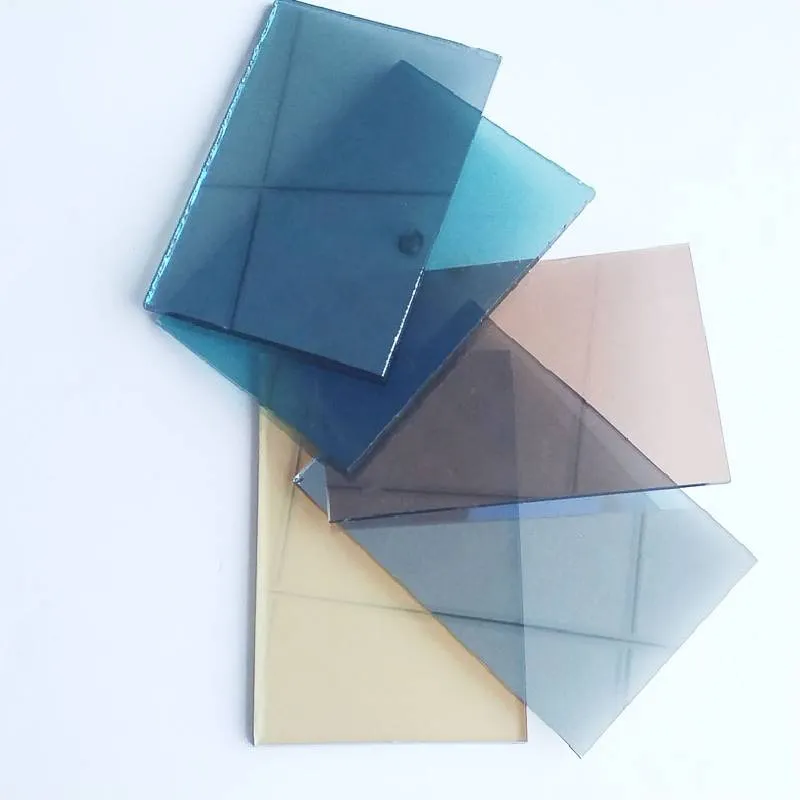

Innovations in tempered glass production continuously push the envelope. Recent advancements include low-emissivity coatings that enhance energy efficiency in buildings, and the incorporation of digital printing techniques that allow customized designs without compromising the glass's structural integrity. Such innovations signal not only technological progress but also a responsiveness to evolving market demands and environmental considerations.

As industries pivot towards sustainability, tempered glass manufacturers are increasingly adopting eco-friendly production methods. Recycling initiatives and waste reduction strategies are being integrated into manufacturing processes, further strengthening the environmental credentials of tempered glass. These measures complement a strategic shift towards reducing carbon footprints and maximizing resource efficiency.

In conclusion, tempered glass production is a field defined by its technical precision, commitment to safety, and constant innovation. It blends expert knowledge with advanced technology and rigorous quality control to produce a material that is as functional as it is beautiful. The industry's dedication to high standards and sustainable practices ensures its products deliver unparalleled safety and reliability, thus earning its place in both professional and everyday environments.

Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu