The Manufacturing of Tempered Glass A Comprehensive Overview

Tempered glass, also known as toughened glass, is a type of safety glass that has been treated through controlled thermal processes to increase its strength compared to standard glass. The manufacturing of tempered glass involves several critical steps that ensure its durability and safety, making it a popular choice in various applications, including architecture, automotive, and interior design.

The first step in the manufacturing process is the selection of raw materials. High-quality silica sand, soda ash, and limestone are primarily used to produce the glass. These materials are carefully mixed and melted in a furnace at temperatures exceeding 1,600 degrees Celsius. This melting process produces a molten glass that is uniform in composition and free from impurities.

Once the glass has melted, it is formed into sheets using different techniques, such as float, casting, or pressing. The float glass method is the most common; it involves pouring molten glass onto a molten tin bath, where it spreads out and forms a flat sheet. After forming, the glass sheets are cooled to room temperature slowly in a process known as annealing. This slow cooling is crucial to alleviate internal stresses within the glass, setting the stage for the next step.

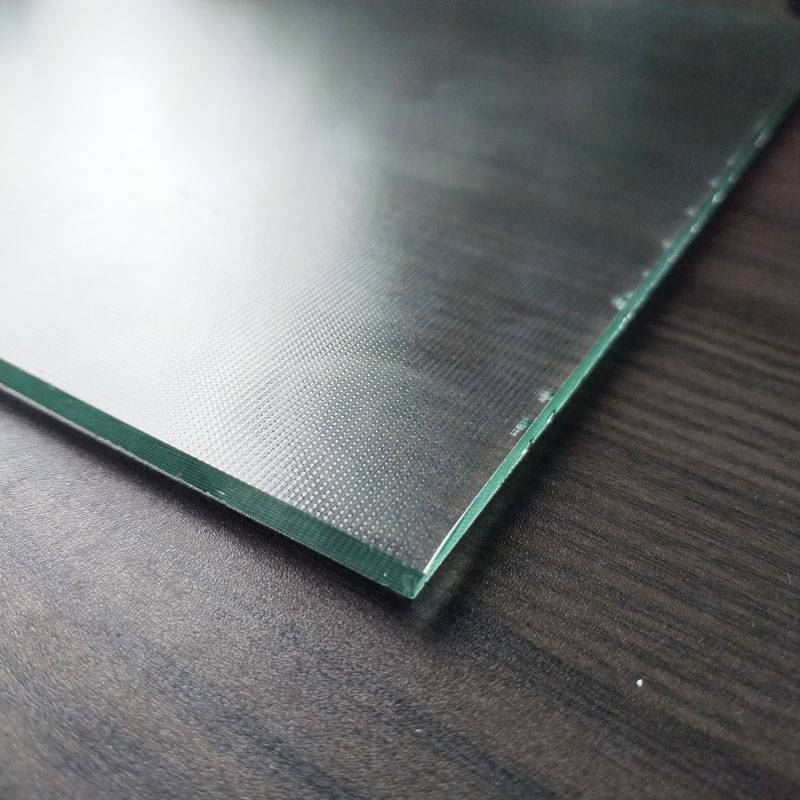

manufacturing of tempered glass

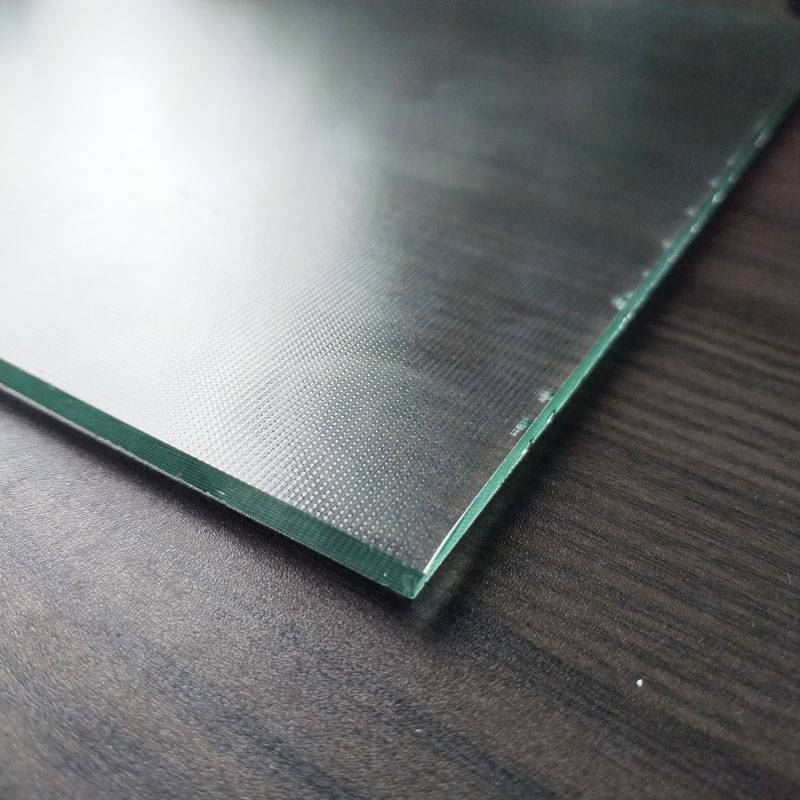

After the glass sheets have been produced, they must be cut to the desired dimensions. Precision cutting machines are used to ensure the glass is trimmed accurately, as any imperfections can affect the structural integrity of the final product. Once cut, the edges of the glass are often polished to remove sharp remnants and prevent chipping, enhancing both safety and aesthetics.

The crucial step in the manufacturing of tempered glass is the heat treatment process. The cut glass sheets are heated in an oven to temperatures between 600 to 700 degrees Celsius. This rapid heating process causes the surface of the glass to expand while the interior remains cooler. After the glass reaches the desired temperature, it is rapidly cooled using high-pressure air in a process known as quenching. This sudden cooling creates a compressive stress on the surfaces of the glass while inducing tensile stresses in the core, ultimately resulting in a product that is up to five times stronger than untempered glass.

Once the tempered glass has been produced, it undergoes rigorous quality control testing to ensure it meets safety standards. Various tests, including impact resistance and thermal stress tests, are conducted to confirm the glass can withstand force and thermal fluctuations. Only after passing these stringent tests is the tempered glass deemed ready for distribution.

In conclusion, the manufacturing of tempered glass is a complex and precise process that ensures the production of a strong, durable, and safe product. From the careful selection of raw materials to the heat treatment that imparts its strength, each step in the production process is vital. As industries increasingly prioritize safety and durability, the demand for tempered glass continues to rise, solidifying its importance in modern construction and design.

Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu