In the ever-evolving glass industry, acid etched frosted glass continues to shape modern architecture and design. With its unique combination of privacy, refined aesthetics, and durability, it offers an irreplaceable solution for both functional and decorative purposes. This article offers an authoritative overview on industry trends, technical parameters, application scenarios, in-depth professional FAQ, interactive charts, and the latest insights surrounding acid etched frosted glass.

Company Introduction

Leading Manufacturer:

[Company Name] specializes in the production, customization, and wholesale of

acid etched frosted glass with a strong focus on technical precision, large-scale supply capability, and international standards.

Product: Acid etched frosted glass customization wholesale

Product Introduction:

Frosted glass is made opaque through a process that roughens or blurs the glass surface. Acid etched glass utilizes abrasives for a frosted appearance and acid treatment for a matte surface finish (applied to one or both sides). It is ideal for shower doors, partitions, office wall panels, and decor projects.

Surface is slightly uneven and marginally thinner, thus not suitable as a mirror.

Industry Trends & Market Outlook for Acid Etched Frosted Glass

The global demand for acid etched frosted glass is projected for steady growth, driven by increasing applications in residential, commercial, and industrial segments. The surge in contemporary architectural designs emphasizing privacy without sacrificing light transmission, eco-friendly construction, and custom aesthetics, positions acid frosted glass as a preferred choice among architects and designers.

As referenced by the Glass on Web Industry Forum and ScienceDirect Journals, technological advances in surface processing and durable coatings are continually optimizing the performance profile of frosted glass acid etching products.

Technical Data Table: Acid Etched Frosted Glass

| Parameter |

Description |

Industry Standard |

Typical Value |

Range |

| Material |

Float Glass / Ultra-clear Glass |

EN 12150 / ASTM C1048 |

Soda-lime Silicate Glass |

3–19mm thick |

| Frosting Process |

Acid Etching (HF solution) |

ISO 12543 |

Uniform Matte Finish |

One or Both Sides |

| Light Transmission |

68%-85% |

GB15763.2 |

Approx. 80% |

Depending on Glass Type |

| Surface Hardness |

Mohs Scale |

>5.5 |

6 |

5.5-7 |

| Privacy (Obscurity) |

Diffuse/Obscure |

Customizable |

High |

Med-High |

| Color |

Natural, Super White, Grey, Bronze, Customized |

N/A |

Clear/White Preferred |

Multi-color Optional |

| Primary Use |

Partition, Doors, Showers, Windows, Décor |

Building Code GB50096 |

Wide Application |

Residential/Commercial |

| Thickness |

3mm, 4mm, 5mm, 6mm, 8mm, 10mm, 12mm, 15mm, 19mm |

±0.2 mm Tolerance |

6mm/8mm Most Popular |

3–19mm Available |

| Customization |

Shapes, Edges, Patterns |

According to Drawing |

Patterns, Logos, Etching |

Fully Custom |

Interactive Data Charts: Trends & Technical Comparison

Application Scenarios for Acid Etched Frosted Glass

Acid etched frosted glass and acid frosted glass have found widespread use in a variety of scenarios owing to their diffuse light transmission, privacy, and elegant matte visual appeal:

- Office Partitions: Enabling light flow while maintaining privacy.

- Shower & Bath Enclosures: Superior water and stain resistance with hygienic surface.

- Residential Decor: Cabinet doors, bedroom dividers, sliding walls for stylish ambiance.

- Hotel & Retail Spaces: Storefronts, display windows, and gallery panels.

- Custom Graphics: Logos, signs, or patterns etched into the glass.

- Hospitals & Clinics: Sanitary, easy-to-clean surface for privacy screens.

- Public Buildings: Balustrades, partitions, or windows balancing transparency and obscurity.

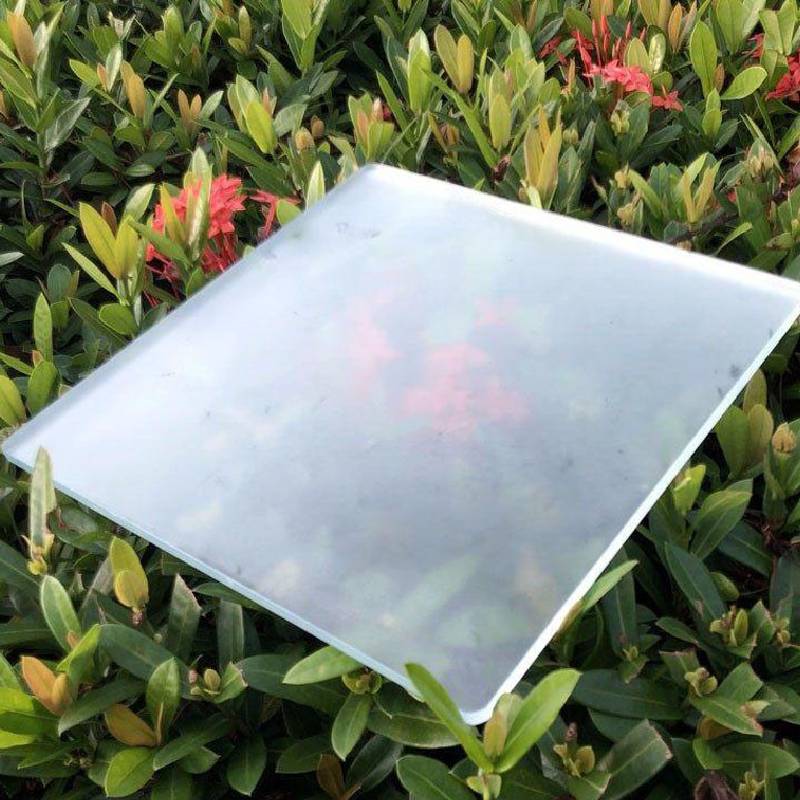

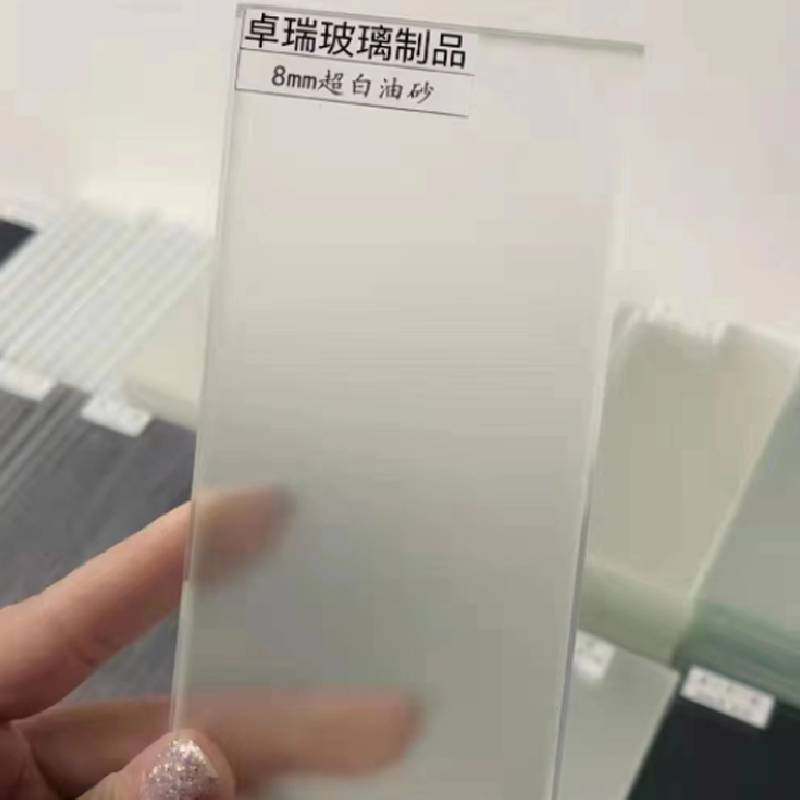

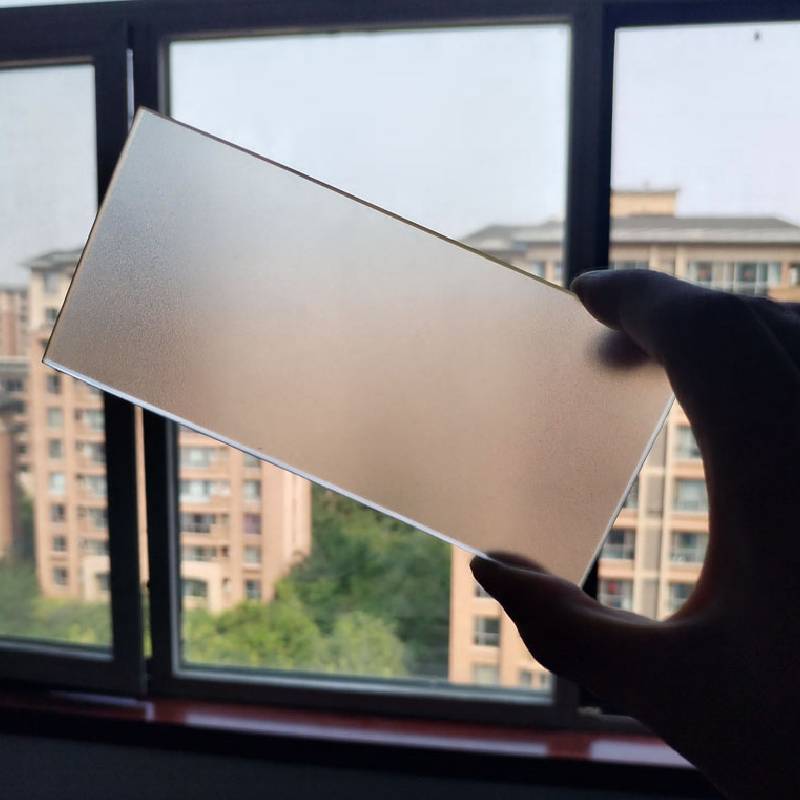

Product Showcase: Acid Etched Frosted Glass Customization Wholesale

Key Features:

- Matte & Smooth Surface

- High Light Diffusion

- Excellent Uniformity

- Fingerprint & Stain Resistant

- Multiple Thicknesses (3–19mm)

- Fully Customizable (Shape, Size, Logo, Pattern)

Available Specifications:

- Material: Soda-lime Glass (Clear/Ultra-clear)

- Finish: One/Both Sides Etched

- Edge: Flat/Arris/Polished/Laminated

- Maximum Panel: 3300mm x 2100mm

- Thickness: 3mm / 4mm / 6mm / 8mm / 10mm / 12mm / 15mm / 19mm

- Custom Patterns: Yes

Professional FAQ: Common Technical Inquiries on Acid Etched Frosted Glass

Frequently Asked Technical Questions

Q1: What material is typically used for acid etched frosted glass?

A1: Acid etched frosted glass is mainly fabricated from high-quality soda-lime float glass or ultra-clear float glass, which ensures optical clarity and uniform frosting outcomes.

Q2: What are the standard and maximum panel sizes?

A2: Standard production sizes include 2440×1830mm, 3300×2100mm & customizable dimensions, with thicknesses ranging from 3mm to 19mm. Large panels up to 3300×2100mm can be supplied upon request.

Q3: How does acid etched glass differ from sandblasted glass?

A3: While both achieve a frosted appearance, acid etched frosted glass typically produces a smoother, more uniform matte finish with better stain and fingerprint resistance compared to sandblasted glass, which may feel rougher and accumulate more dust over time.

Q4: Is there an industry standard for the acid used in frosting?

A4: Yes, hydrofluoric acid (HF) is the common etchant, used according to international safety guidelines (see OSHA Guidelines). Exclusive recipes ensure consistency and depth for frosted glass acid etching.

Q5: What installation standards should be followed?

A5: Installation must adhere to codes such as EN 12150 and ASTM C1048 for safety glass, requiring proper support frames, protected edges, tested adhesives, and, where required, use of tempered or laminated acid etched panels.

Q6: Can acid etched glass support custom artwork and patterns?

A6: Absolutely. Acid etched frosted glass can be precisely patterned using masking techniques and selective etching to realize logos, graphics, and repeat motifs—with high consistency even in large batches.

Q7: What is the maintenance protocol for acid frosted glass?

A7: Clean gently using mild detergent and water; avoid abrasive pads. Acid frosted surfaces are highly resistant to fingerprints and smudging, requiring less maintenance than sandblasted alternatives.

Q8: Is acid etched frosted glass suitable for load-bearing or safety-critical installations?

A8: When produced from tempered or laminated glass, acid etched panels meet the requirements for certain load-bearing roles, such as balustrades, but always consult local codes and structural engineers for safety compliance.

SEO Optimization Strategy: Acid Etched Frosted Glass & Related Keywords

All references to acid etched frosted glass, acid frosted glass, and frosted glass acid etching are optimized throughout this page with natural, contextual density to maximize organic traffic and ranking for related queries. Technical data, authoritative citations, and detailed FAQ are all structured to support Google E-E-A-T (Experience, Expertise, Authoritativeness, Trustworthiness) signals.

Industry Authority & Resources

Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu