Understanding Clear Annealed Float Glass Properties, Uses, and Benefits

Clear annealed float glass is a fundamental material widely used in the construction, automotive, and furniture industries, among others. Its production, characteristics, and applications highlight its versatility and importance across various sectors. This article will explore the properties, manufacturing process, and benefits of clear annealed float glass.

What is Clear Annealed Float Glass?

Clear annealed float glass is a type of glass that is produced through the float glass process. During this process, molten glass is floated on top of molten tin, resulting in a smooth, flat surface. The term annealed refers to the controlled cooling process that helps relieve internal stresses within the glass, leading to improved durability and uniformity. As a result, clear annealed float glass offers excellent optical clarity, high transparency, and a flawless finish.

Properties of Clear Annealed Float Glass

One of the standout properties of clear annealed float glass is its exceptional clarity. The glass is free from any significant tint, allowing maximum light transmission. This characteristic makes it ideal for applications where visibility is crucial. Moreover, clear annealed float glass has a uniform thickness, which contributes to its aesthetic appeal and functional performance.

The glass is also relatively easy to cut, shape, and fabricate, making it a preferred choice for a wide variety of applications. Its surface is smooth and can be enhanced with coatings to improve insulation, UV protection, or energy efficiency. Additionally, clear annealed float glass has good resistance to environmental factors like moisture and humidity, making it a suitable option for both indoor and outdoor applications.

Manufacturing Process

The float glass manufacturing process involves several key steps. Initially, raw materials such as silica sand, soda ash, and limestone are combined and melted at high temperatures in a furnace. Once this mixture forms molten glass, it is poured onto a surface of molten tin. The glass spreads out and flattens due to gravity, creating a uniform thickness.

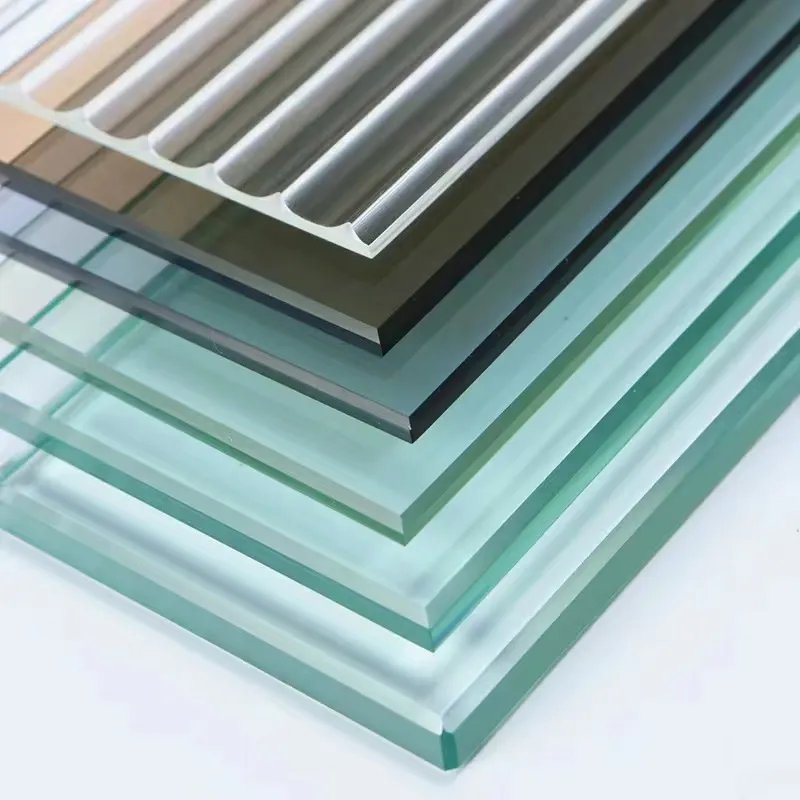

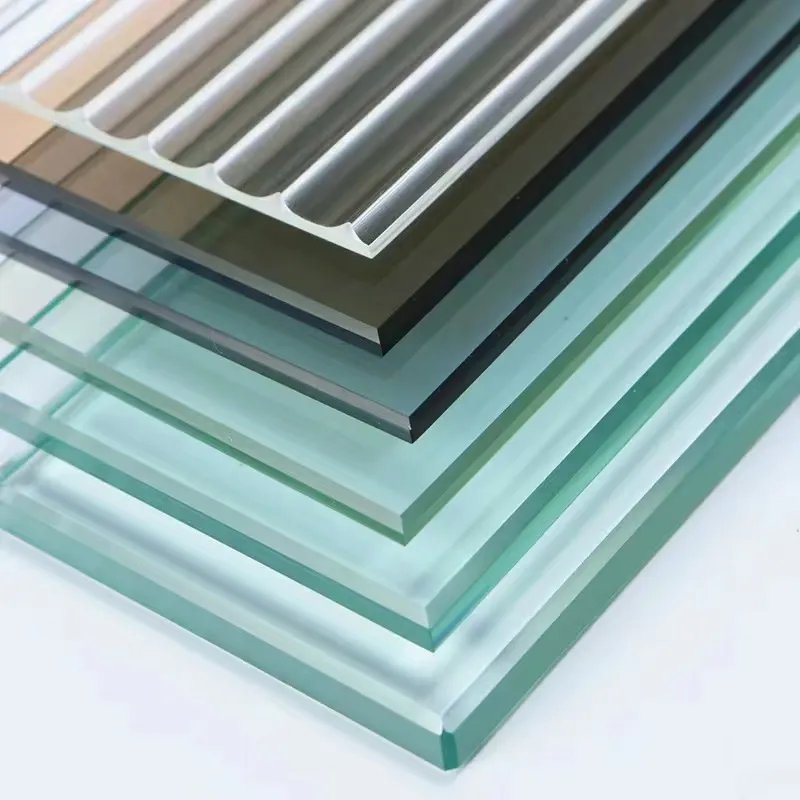

clear annealed float glass

The next stage is annealing, where the glass is slowly cooled in a controlled environment to prevent thermal shocks. This process enhances the physical properties of the glass, including its strength and resistance to breakage. Finally, the glass is cut to size and may undergo additional processing based on customer specifications, such as polishing or coating.

Applications of Clear Annealed Float Glass

Clear annealed float glass is utilized in numerous applications due to its desirable properties. In commercial and residential construction, it is commonly used for windows, facades, and interior partitions. The glass allows natural light to penetrate while providing a clear view of the outside, enhancing the aesthetic appeal of buildings.

In the automotive industry, clear annealed float glass is employed in windshields and side windows, where visibility and safety are paramount. Its clarity and durability make it suitable for demanding environments.

Additionally, the glass is widely used in furniture design, such as tabletops and display cases, where a sleek appearance is desired. It can also be found in various decorative applications, including mirrors and glass doors.

Benefits of Clear Annealed Float Glass

The benefits of clear annealed float glass are numerous. Its excellent optical properties ensure that spaces are bright and welcoming. The glass is also cost-effective, making it an economical option for both large-scale and small projects. Furthermore, its ease of maintenance allows for straightforward cleaning and care over time, ensuring long-lasting transparency and beauty.

In conclusion, clear annealed float glass is an essential material with broad applications across various industries. Its clarity, durability, and versatility make it a preferred choice for architects, designers, and manufacturers alike. As technology advances, it is likely that the production methods and applications of this remarkable material will continue to evolve, increasing its significance in modern construction and design.

Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu