The Future of Low Iron Glass Manufacturing

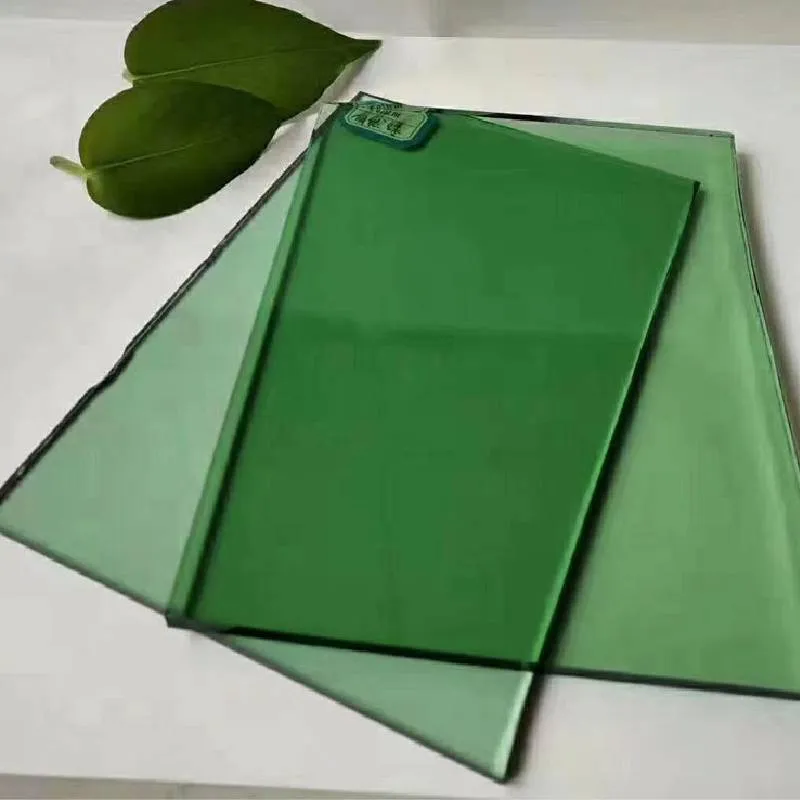

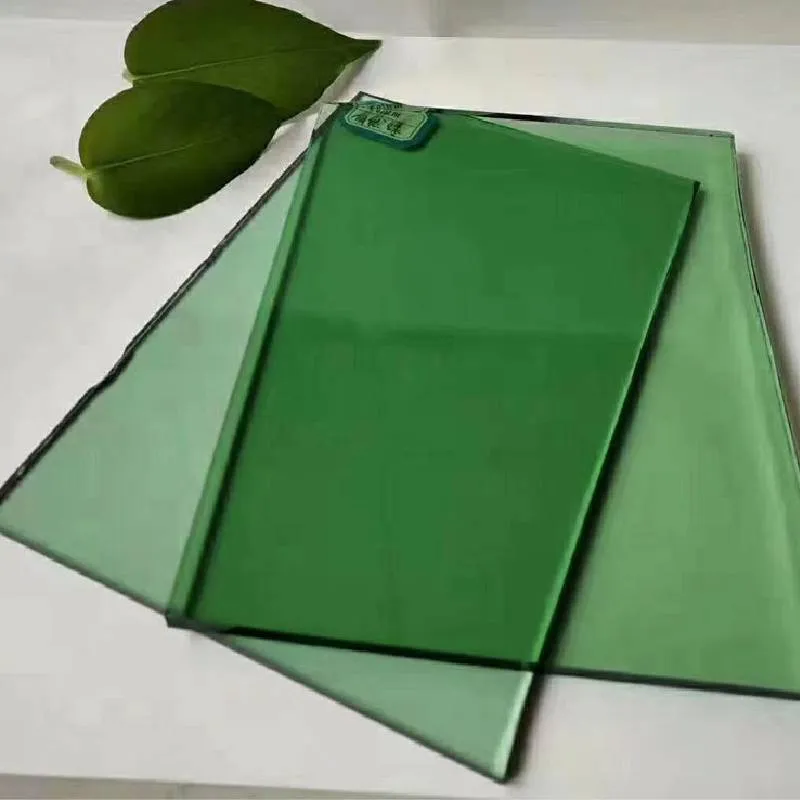

In today’s rapidly evolving industrial landscape, the demand for high-quality materials is at an all-time high. Among these, low iron glass has emerged as a vital component across various sectors including architecture, automotive, and solar energy. Unlike standard glass, low iron glass contains significantly reduced iron content, allowing for superior transparency and clarity. This unique property makes it an ideal choice for applications that require optimal light transmission and aesthetic appeal.

The Future of Low Iron Glass Manufacturing

Once mixed, the materials undergo high-temperature melting in large furnaces. These furnaces are designed to reach temperatures exceeding 1,600 degrees Celsius. Such extreme heat is essential to dissolve the raw ingredients completely, resulting in a molten glass that can be easily shaped. Following the melting stage, the glass is formed into sheets through processes such as floating or pressing, depending on the desired thickness and dimensions. The float glass method, notably, allows for large, flat panels that are crucial in construction and design.

low iron glass factory

After formation, the glass undergoes rigorous annealing, a critical step that involves cooling the glass slowly to relieve internal stresses, ensuring structural integrity. Quality control is paramount throughout the manufacturing process. Advanced inspection technologies are employed to detect any defects, such as bubbles or impurities. This stringent quality assurance guarantees that only the finest low iron glass leaves the factory, meeting the exacting standards of clients across various industries.

The applications of low iron glass are vast and varied. In the construction sector, it allows architects to design visually striking buildings that maximize natural light, while also enhancing energy efficiency. Solar panels, utilizing low iron glass, achieve higher energy conversion efficiencies due to improved light transmission. Additionally, the automotive industry benefits from using low iron glass in windshields and windows, offering improved visibility and aesthetic appeal.

In conclusion, low iron glass factories stand at the forefront of innovation in the glass manufacturing industry. By prioritizing purity and quality, these facilities not only cater to current market demands but also contribute to sustainable practices by promoting energy efficiency and aesthetic architecture. As the world moves towards more environmentally conscious and visually appealing designs, the role of low iron glass will undoubtedly continue to grow, shaping the future of modern construction and technology.

Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu